Flue plate laying machine applicable to large-diameter flue plate and laying method thereof

A flue board and laying machine technology, which is applied in mining equipment, earth-moving, mine/tunnel ventilation, etc., can solve the problems of low work efficiency and the inability of the flue board laying device to be tunneled at the same time, so as to improve construction safety. , The effect of improving laying efficiency and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

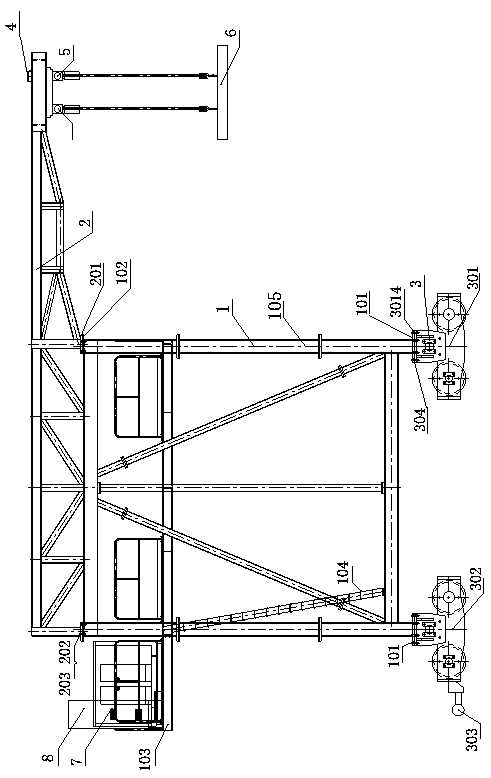

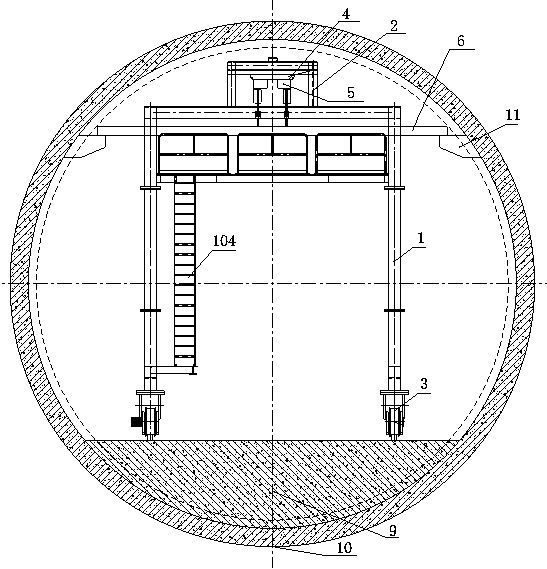

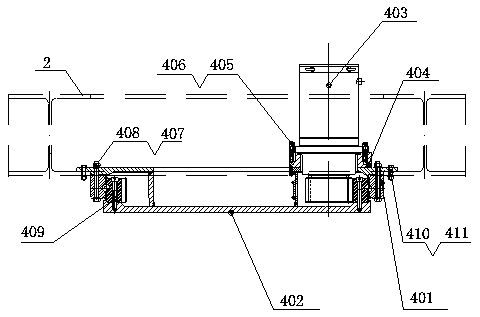

[0033] Embodiment 3, a kind of laying method applicable to the flue plate laying machine of large diameter, the steps are as follows: as Figure 1~2 Shown as: S1: The active trailer 1 is located at the rear of the backstage trailer of the roadheader. During the tunneling process of the roadheader, the active trailer 1 moves in the same direction with the roadheader under the action of the wheel set driving mechanism 3 .

[0034] S2: The rotation angle of the slewing system 4 is at 0°. The electric hoist crane 501 of the hoisting system 5 lifts the flue plate 6 in the axial direction and slowly rises. When hoisting the flue plate 6, it is controlled by the load cell Lift the weight to prevent overloading.

[0035] S3: When the flue plate lifting height is higher than the flue plate support base 11 fixed on the upper part of the segment, the slewing system 4 rotates 90° in the forward direction or 90° in the reverse direction, so that the slewing angle of the slewing system 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com