Long-distance large-diameter cable laying system and method under complex terrain

A complex terrain and long-distance technology, applied in the field of power transmission and transformation engineering, can solve problems such as cables being impacted or squeezed by foreign objects, cable protective layer wear, and construction personnel squeezed, etc., to improve safety, improve work efficiency, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

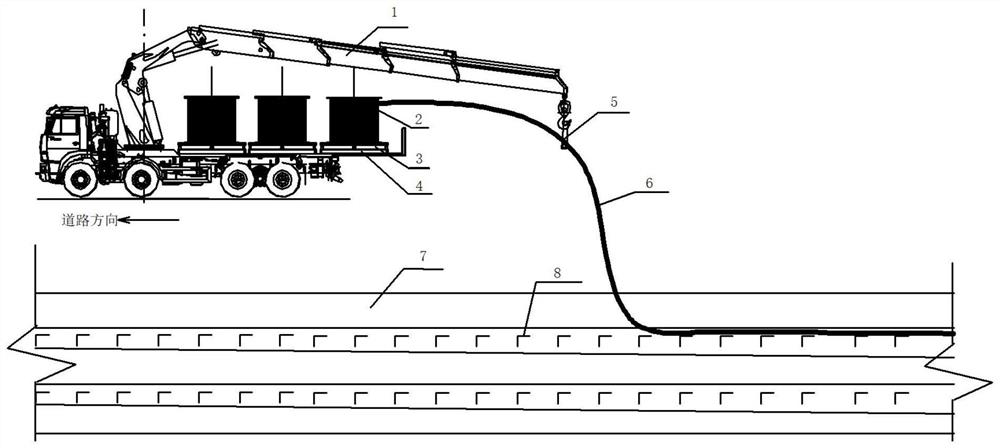

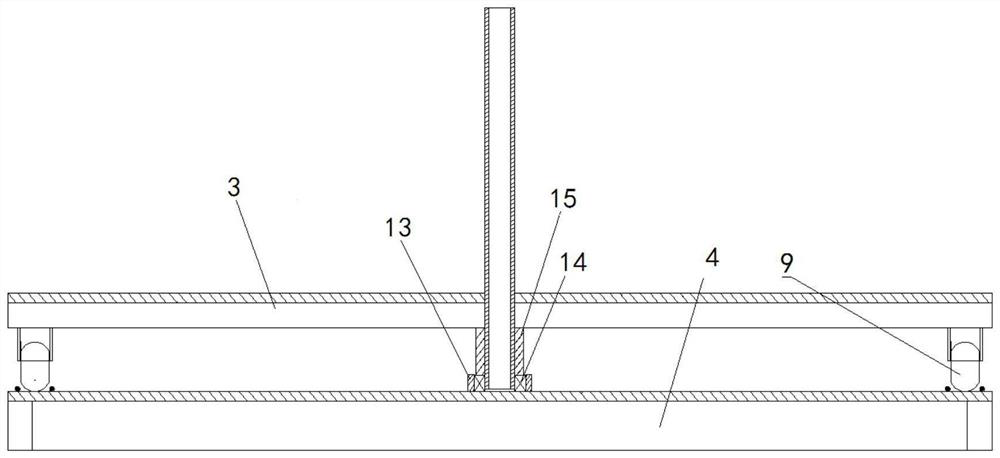

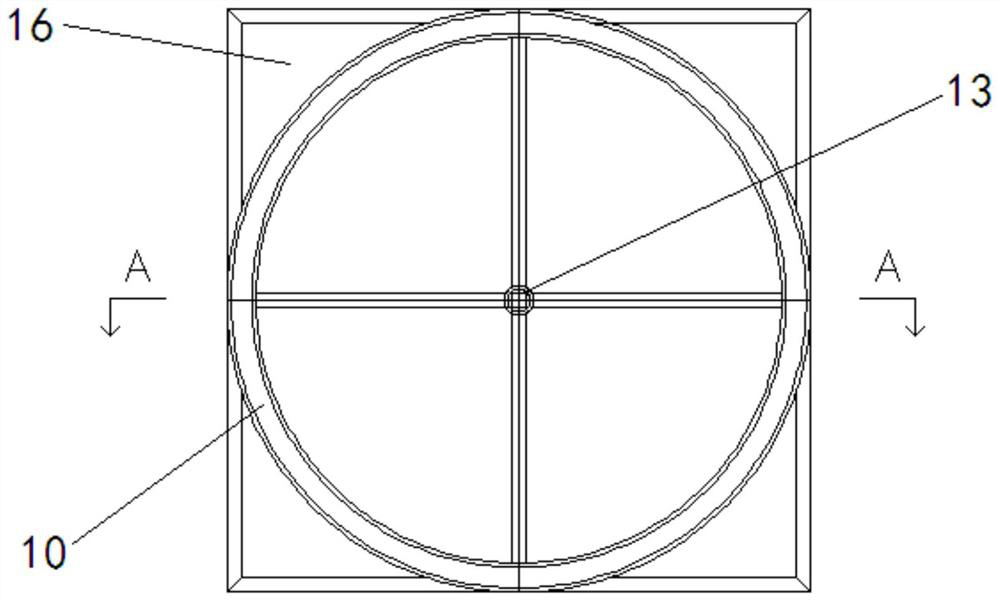

[0038] In a typical embodiment of the present invention, such as Figure 1-Figure 6 As shown, a long-distance and large-diameter cable deployment system under complex terrain is proposed, including a vertical cable deployment device, an auxiliary engineering vehicle 1 and a guide pulley block 5 .

[0039] Among them, the vertical cable deployment device is set on the flat plate of the auxiliary engineering vehicle 1, mainly used for the support of the cable reel 2, the guide pulley block 5 is arranged at the end of the boom of the auxiliary engineering vehicle 1, and the cable 6 wound on the cable reel 2 Through the guiding effect of the guide pulley group 5, it is laid in the excavated cable trench 7, and the cable bracket 8 is also provided in the cable trench 7, which not only facilitates the classified laying of the cables 6, but also effectively prevents the heat released by the cables from affecting the performance of the cables. Ampacity.

[0040] Such as figure 2 As...

Embodiment 2

[0061] In another typical embodiment of the present application, the method for using the long-distance and large-diameter cable deployment system under complex terrain as described in Embodiment 1 is provided, specifically as follows:

[0062] Step 1: Design according to the size of the cable reel 2, make and process one piece each of the base 4 and the rotating bracket 3, except for the assembly surface, the outer surface of the parts is treated with paint and anticorrosion; the CE standard thrust bearing is used, and the assembly is completed Vertical cable deployment device;

[0063] Step 2: Place the assembled vertical cable deployment device on the center of the auxiliary engineering vehicle 1 flat panel, fix the base 4 on the auxiliary engineering vehicle 1 flat panel, and keep the rotating bracket 3 flexibly rotating in the horizontal direction;

[0064] Step 3: Calculate the length of the deployed cable 6 according to the design drawings, deploy the weight of the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com