Roasted eel continuous processing production line system and roasted eel processing method

A processing method and production line technology, which are applied in the direction of processing fish, baking, special commodity baking, etc., to achieve the effect of high automatic cutting effect, improving flowability, improving processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

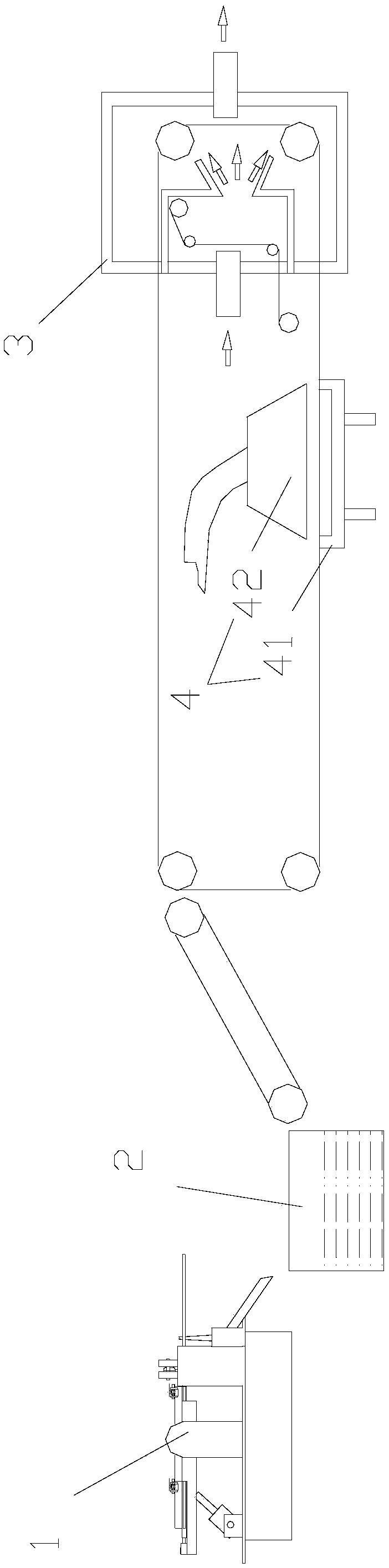

[0058] Such as figure 1 As shown, this embodiment discloses a continuous processing production line system for grilled eel, which includes a slicing mechanism 1, a fish removal tank 2, an air drying device 3, and a barbecue device 4 in the sequence of the process flow.

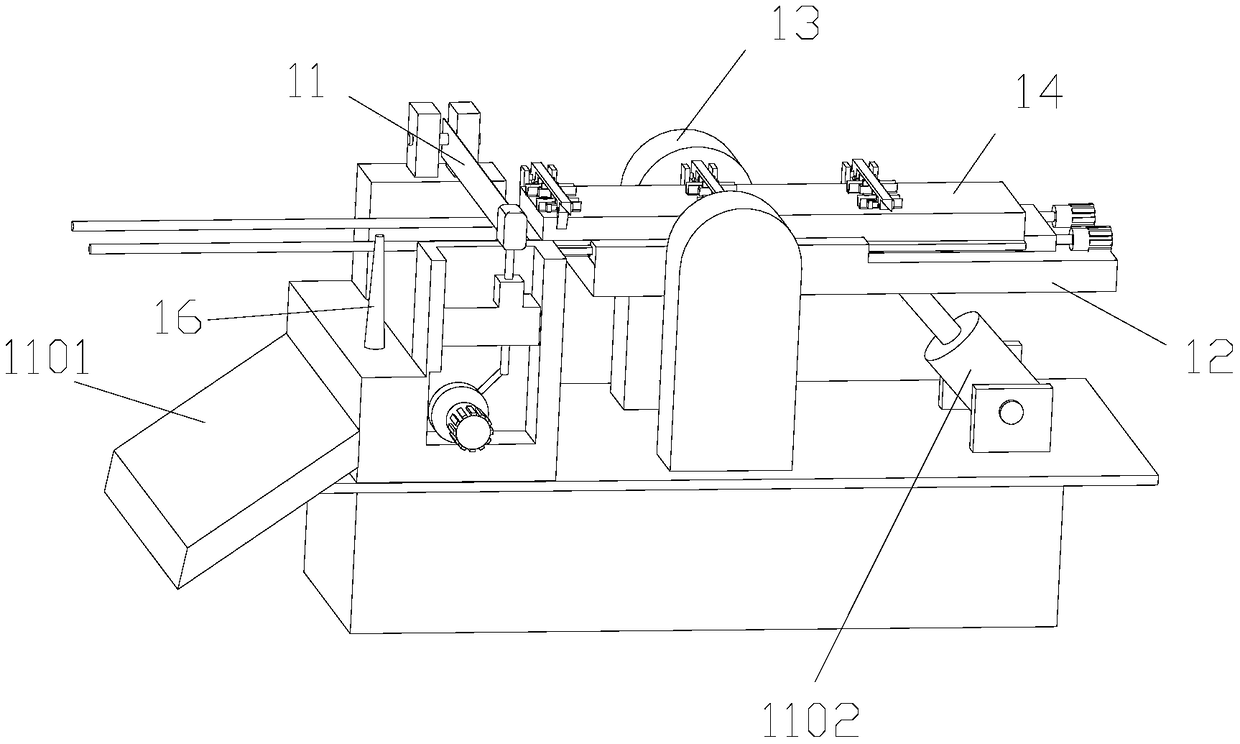

[0059] Such as figure 2 As shown, the slicing mechanism 1 includes a cutting device 11, a bottom plate 12, a pivot seat 13, a sliding plate 14, a movable clamping and limiting device, and a top rod 16.

[0060] Such as Figure 3-5 As shown, the middle section of the bottom plate 12 is pivotally connected to the pivot seat 13, and the sliding plate 14 can slide back and forth on the bottom plate 12. There are multiple movable clamping and limiting devices, which are arranged equidistantly from front to back along the length direction of the sliding plate 14. Each movable clamping and limiting device includes a fixed seat 151, a cantilever 152, a first screw 153, a left limiting member 154, and a right limiting memb...

Embodiment 2

[0075] Such as Picture 11 , 12 As shown in Figure 13, the difference between this embodiment and the above-mentioned embodiment is that the bottom surface of the free end of the cantilever 152 is an inclined surface 1521 with a low front and a high rear. When the rear edge of the bottom surface of the free end of the cantilever 152 contacts the top rod 16, the rear edge is flush with the top surface of the top rod 16 or the rear edge is slightly higher than the top surface of the top rod 16. Figure 19 The direction of the middle arrow is the direction of the skateboard 14.

[0076] In this way, when the rear edge of the bottom surface of the free end of the cantilever 152 moves to the position where it is in contact with the top rod 16, the bottom surface of the free end of the cantilever 152 is an inclined surface 1521 that is low in the front and high in the back. When moving diagonally, the top rod 16 can continue to give an upward vertical component to the free end of the ca...

Embodiment 3

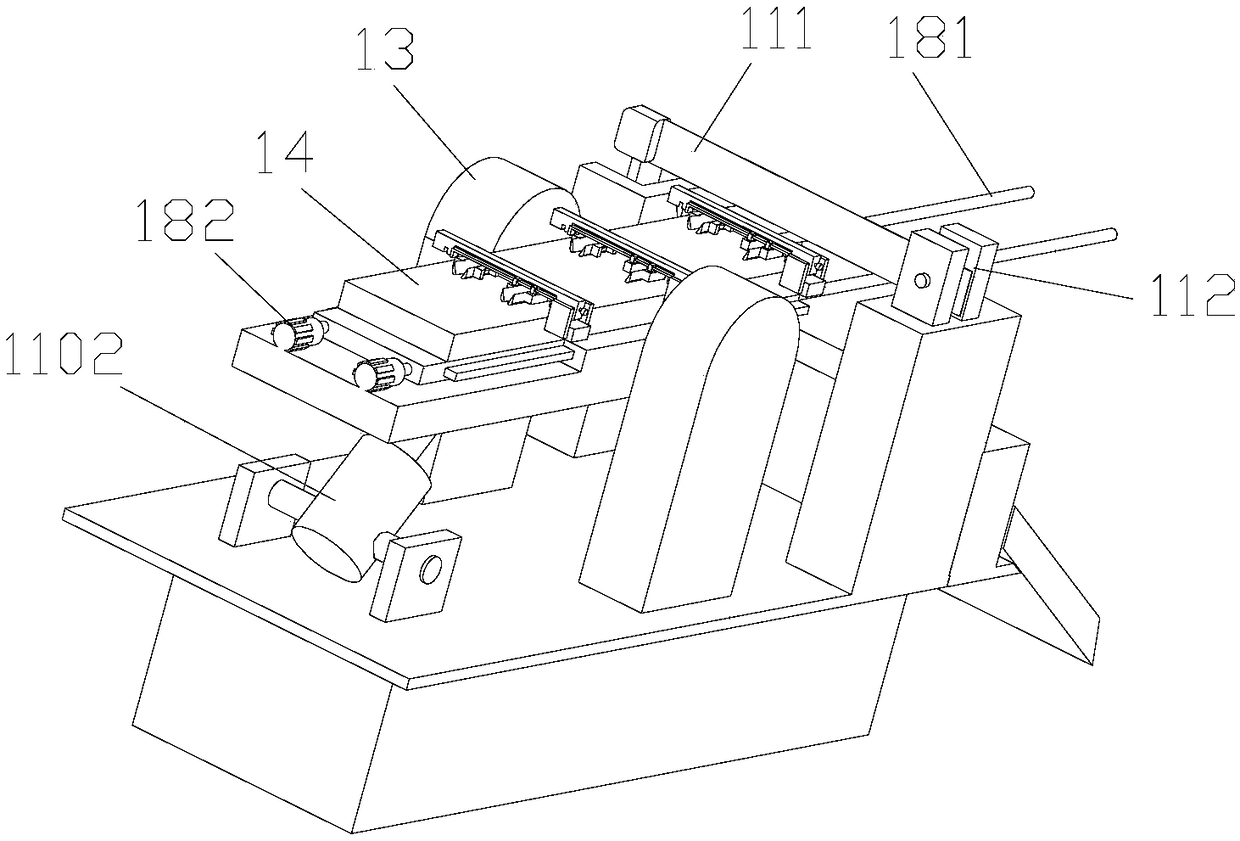

[0078] Such as Figure 15 As shown, the difference between this embodiment and the above-mentioned embodiment is that the ejector rod 16 drives it to reciprocate vertically through the first transmission mechanism, and the upward movement of the ejector rod 16 can push the free end of the cantilever 152 in the engaged state to Separate from the bottom plate 12. The cutting device 11 includes a cutting knife 111, a cutting knife base 112, and a second transmission mechanism. One end of the cutting knife 111 is hinged with the cutting knife base 112, the other end of the cutting knife 111 is a free end, and the free end of the cutting knife 111 is from the left The sliding track across the sliding plate 14 to the right or from right to left is connected to the second transmission mechanism, and the cutting knife 111 is driven to swing up and down through the second transmission mechanism. The first transmission mechanism includes a first guide sleeve 171, a first connecting rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com