Patents

Literature

301 results about "Phosphinidene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry phosphinidenes (IUPAC: phosphanylidenes, or in older chemistry phosphinediyls) are the phosphorus analogs of carbenes and nitrenes, having the general structure RP. The name originated from the parent compound, phosphinidene (HP). They can exist in either a singlet state or triplet state, with the triplet state being lower in energy.

Halogen-free flame retardant polyamide composition with improved electrical properties

Owner:SABIC GLOBAL TECH BV

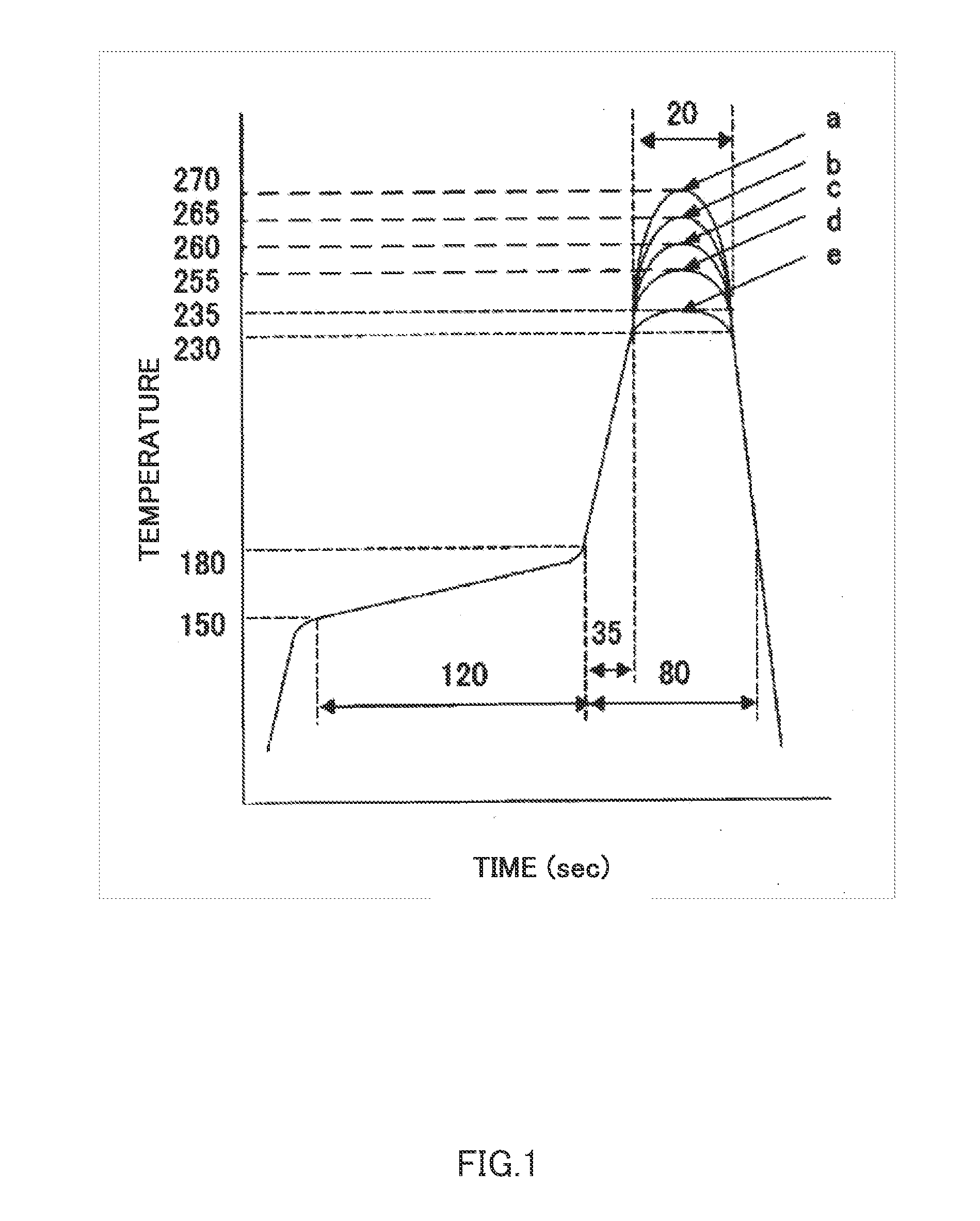

Process for preparing thermoplastic vulcanizates

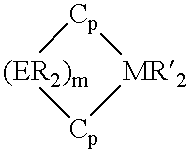

This invention includes a process for forming a thermoplastic vulcanizate comprising: (a) admixing a C-H insertion curing agent with at least one elastomeric phase polymer to form a first admixture; (b) admixing at least one non-elastomeric polyolefin with the first admixture to form a second admixture; and (c) heating the second admixture to a temperature at least the decomposition temperature of the curing agent to crosslink the elastomeric phase while mixing the admixture to an extent sufficient to result in the formation of a thermoplastic material, hereinafter referred to as a thermoplastic vulcanizate, and optionally including an additional step (d) of shaping the resulting thermoplastic vulcanizate, especially by heating and foaming or molding the TPV. The C-H insertion curing agent is preferably selected from alkyl and aryl azides (R-N3), acyl azides (R-C(O)N3), azidoformates (R-O-C(O)-N3), sulfonyl azides (R-SO2-N3), phosphoryl azides ((RO)2-(PO)-N3), phosphinic azides (R2-P(O)-N3) and silyl azides (R3-Si-N3), with poly(sulfonyl azide) most preferred. Additionally, the invention includes a thermoplastic vulcanizate comprising a blend of: (1) an elastomeric phase crosslinked using a C-H insertion curing agent dispersed in; (2) at least one non-elastomeric thermoplastic polyolefin. The invention also includes a foamable composition comprising (1) an elastomeric phase crosslinked using a C-H insertion curing agent dispersed in; (2) at least one non-elastomeric thermoplastic polyolefin; and (3) from about 0.1 to about 25 percent by weight based on the combined weight of components (1) and (2) of at least one foaming agent as well as a fabricated part, cable jacket, cable insulation, or foam comprising the thermoplastic vulcanizate or the invention or resulting from the process of the invention.

Owner:THE DOW CHEM CO

Halogen-free flame retardant polyamide composition with improved electrical and flammability properties

Flame retardant polyamide compositions are provided containing a polyamide; a flame retardant system including a metal phosphinate or diphosphinate salt and a nitrogen compound; an aromatic polymer, and optionallly untreated nanoclay having an aspect ratio of about 100 to about 1000.

Owner:SHPP GLOBAL TECH BV

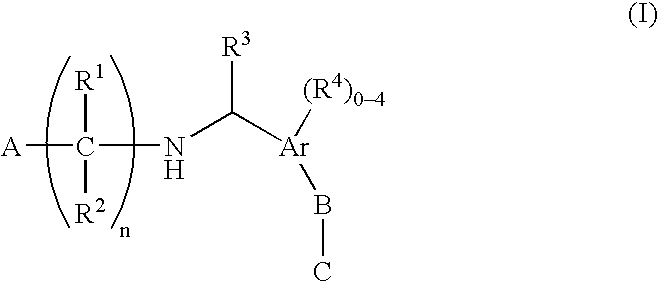

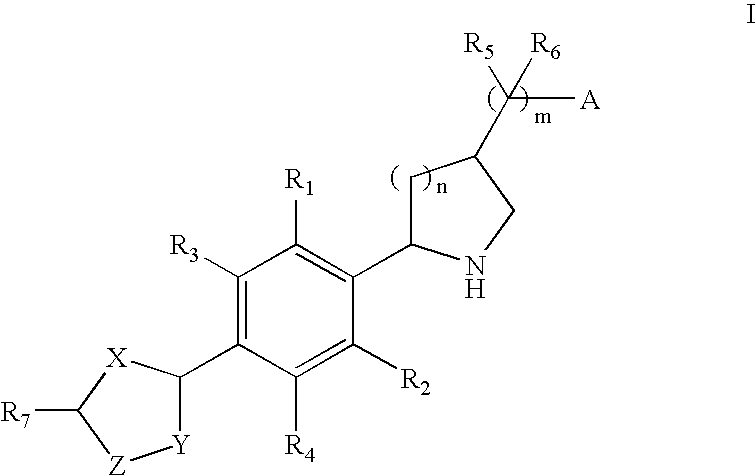

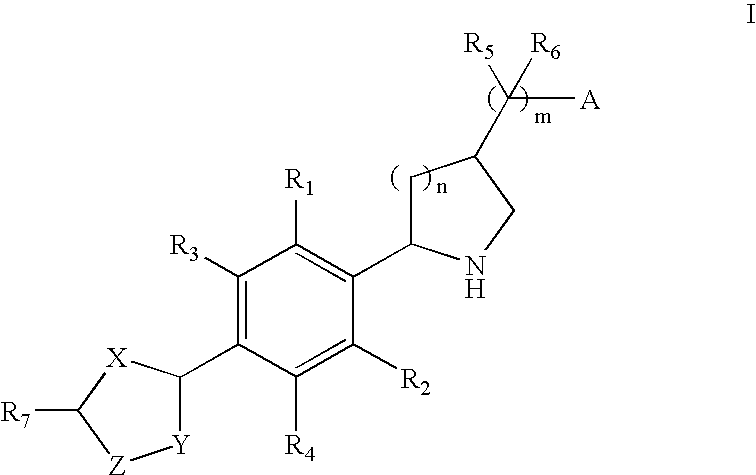

N-(benzyl)aminoalkylcarboxylates, phosphinates, phosphonates and tetrazoles as edg receptor agonists

The present invention encompasses compounds of Formula (I) as well as the pharmaceutically acceptable salts and hydrates thereof. The compounds are useful for treating immune mediated diseases and conditions, such as bone marrow, organ and tissue transplant rejection. Pharmaceutical compositions and methods of use are included.

Owner:MERCK SHARP & DOHME CORP

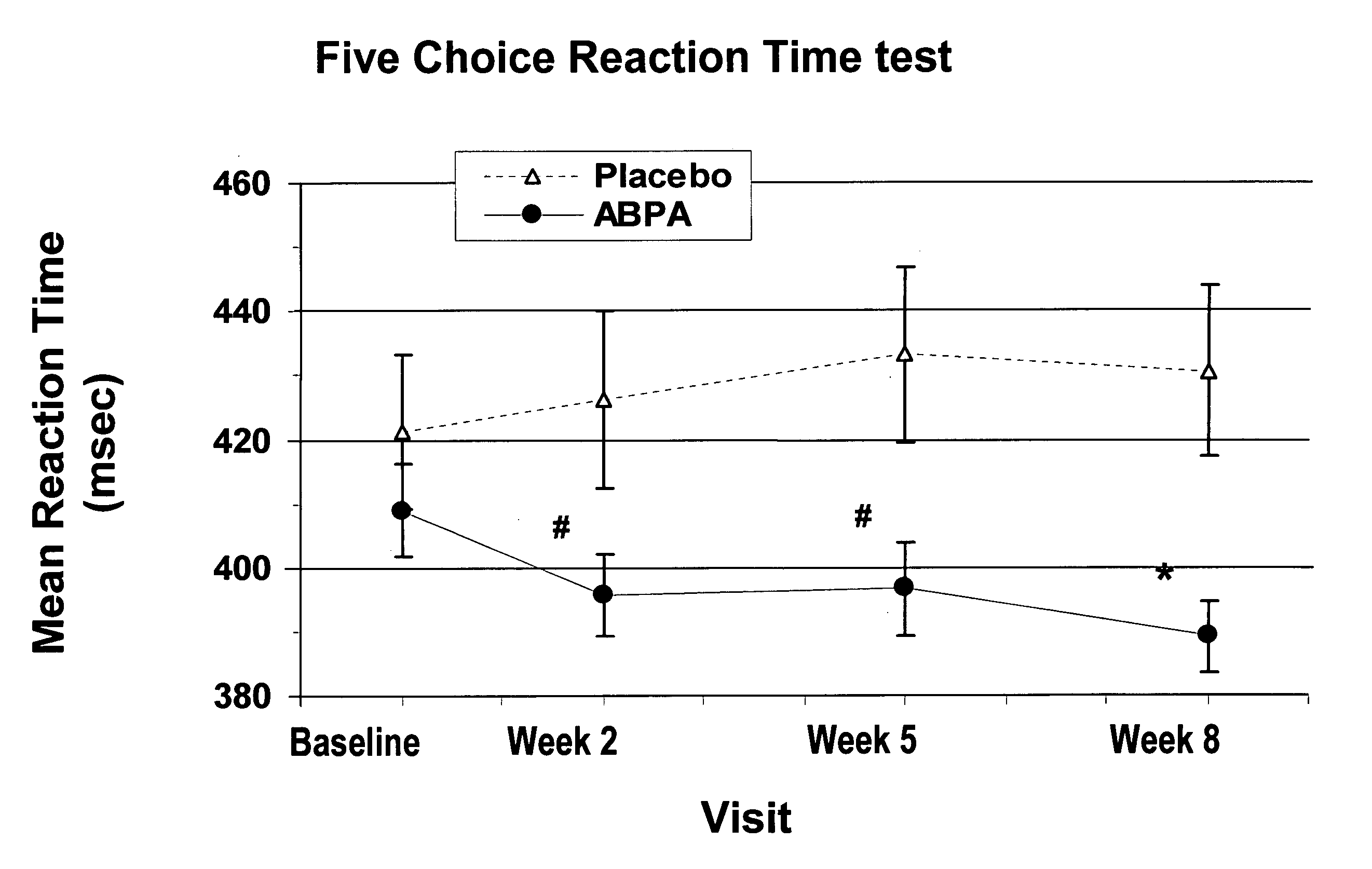

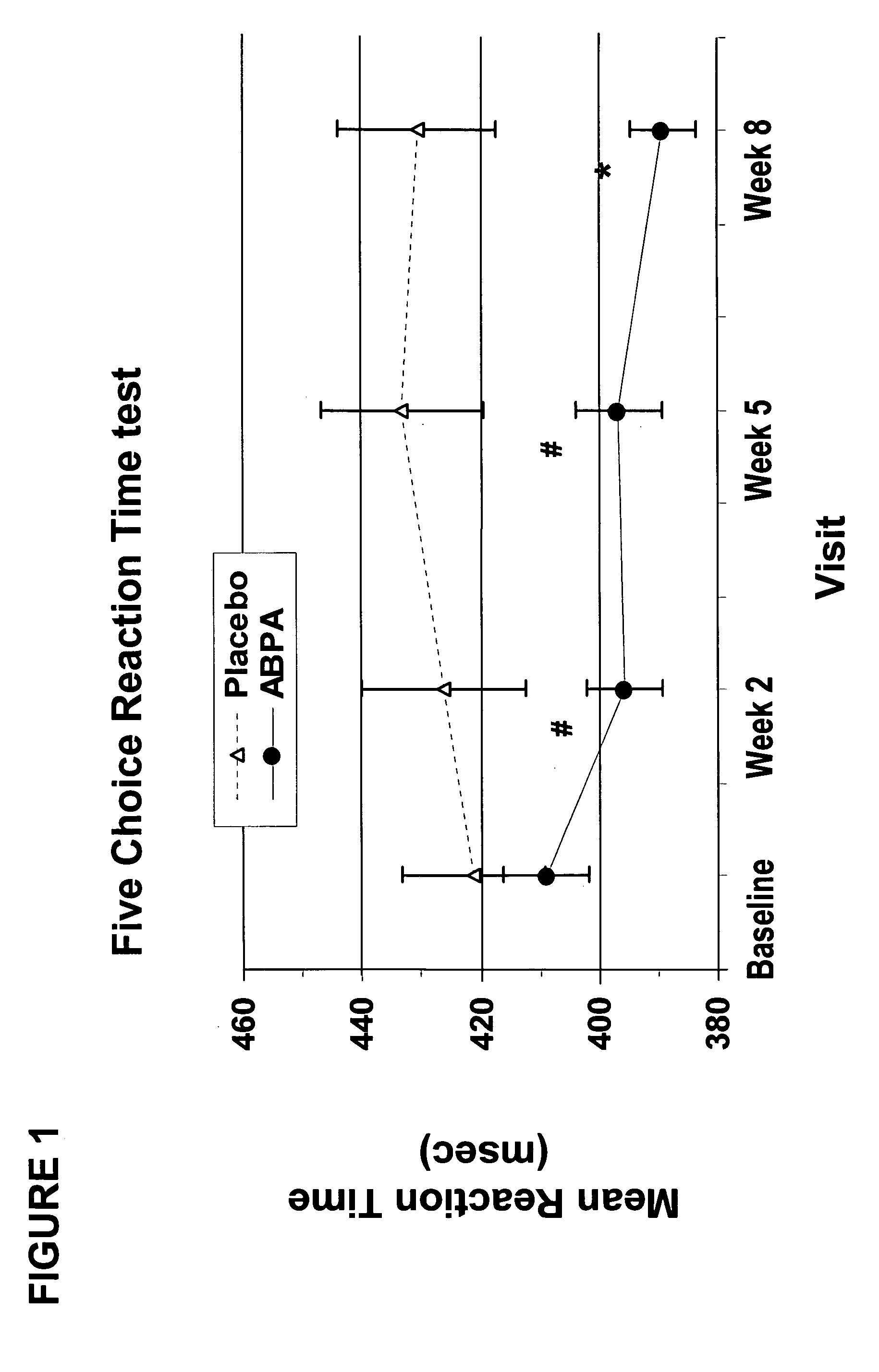

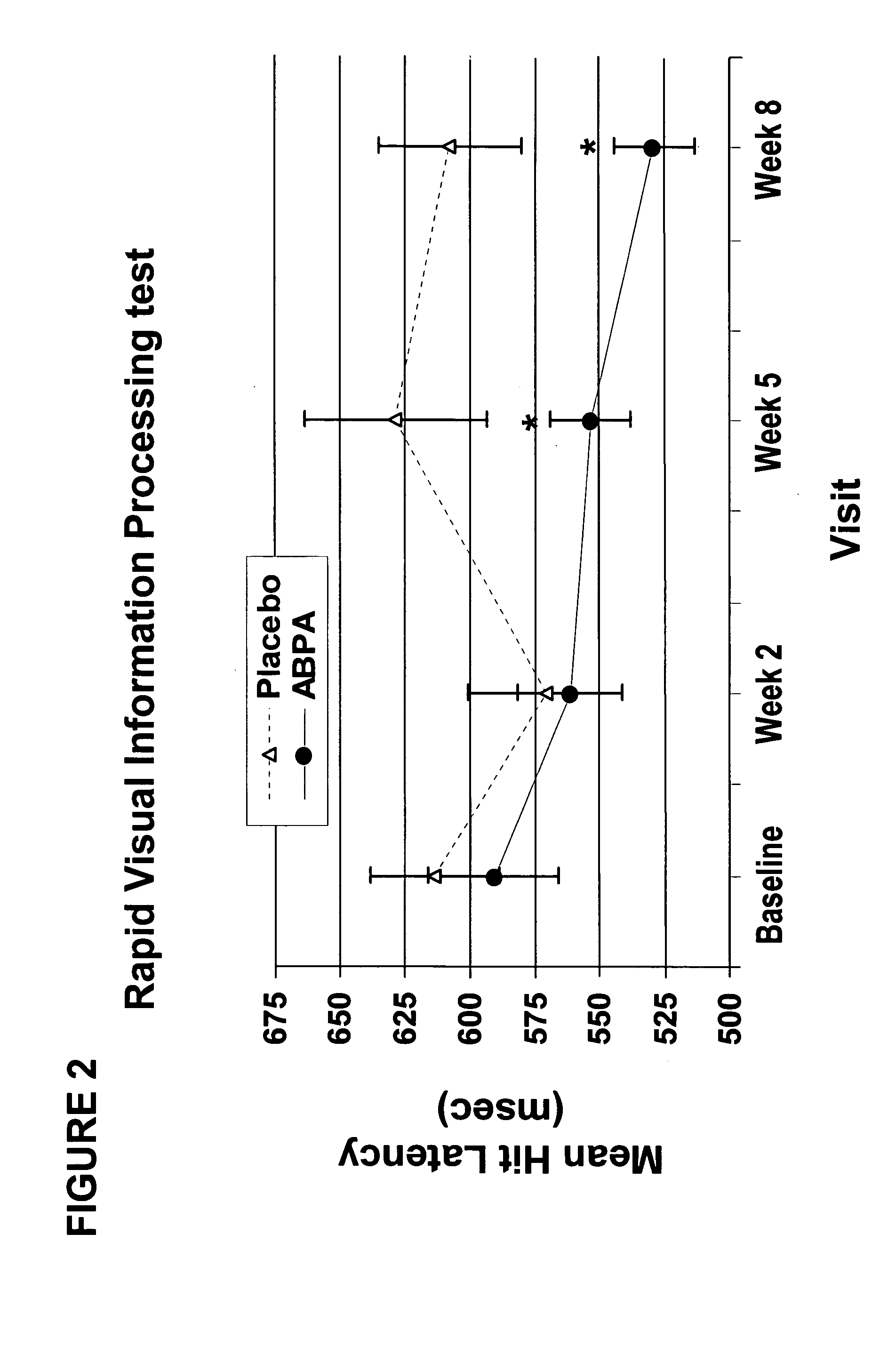

Treatment of attention disorders

InactiveUS20050187196A1Raise attentionBiocidePhosphorous compound active ingredientsPhosphinic AcidsAttention disorders

The invention provides methods and medicaments for improving attentiveness in humans, including subjects diagnosed with attention disorders. In one aspect, a GABAB receptor antagonist, such as 3-aminopropyl-(n-butyl)-phosphinic acid (ABPA), is used to improve attention.

Owner:SAEGIS PHARMA

Flame-retardant resin composition

ActiveUS20080167406A1Improve flame retardant performanceImprove machinabilityGroup 5/15 element organic compoundsPolytetramethylene terephthalateElastomer

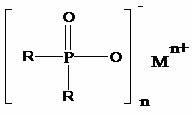

A flame-retardant resin composition comprises 25 to 150 parts by weight of (B) a thermoplastic polyester elastomer, 5 to 40 parts by weight of (C) a phosphinic acid compound comprising a salt of at least one member selected from the group consisting of a phosphinic acid, a diphosphinic acid, and a polymerized product thereof, and 0.5 to 20 parts by weight of (D) an epoxy compound, relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin. Such a flame-retardant resin composition is useful for various molded products and for covering the surface of an electric wire, or the like. The present invention provides a halogen-free flame-retardant resin composition which has a high heat resistance and a high flame retardancy and is excellent in hydrolysis resistance, abrasion resistance, and moldability (e.g., extrusion properties).

Owner:WIN TECH POLYMER LTD

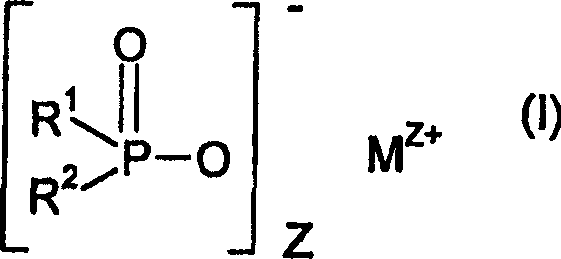

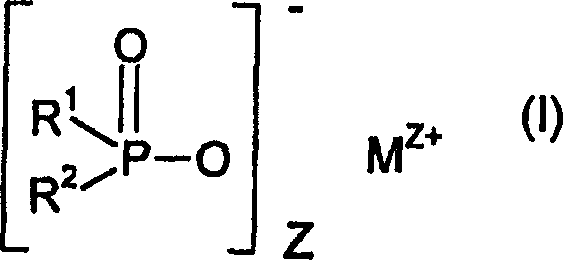

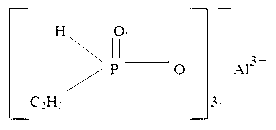

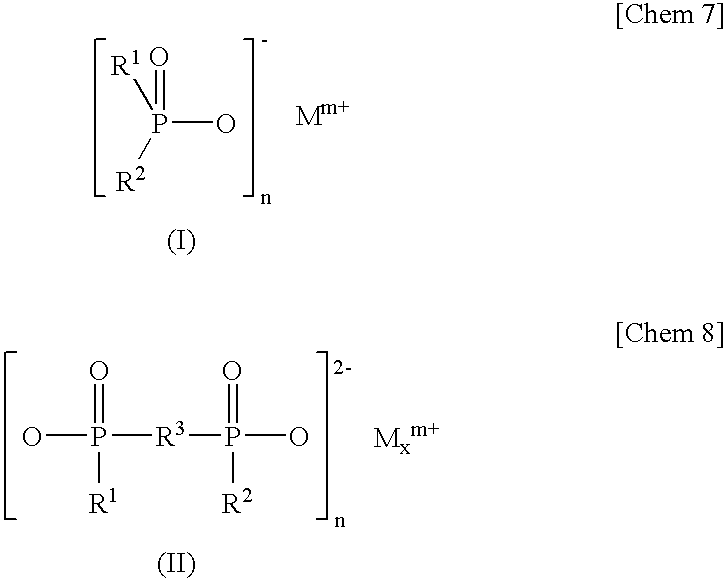

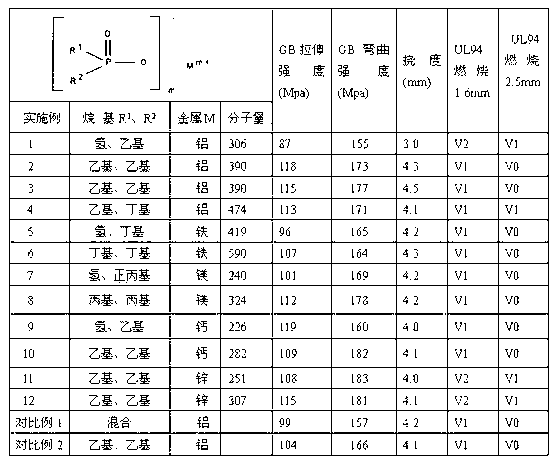

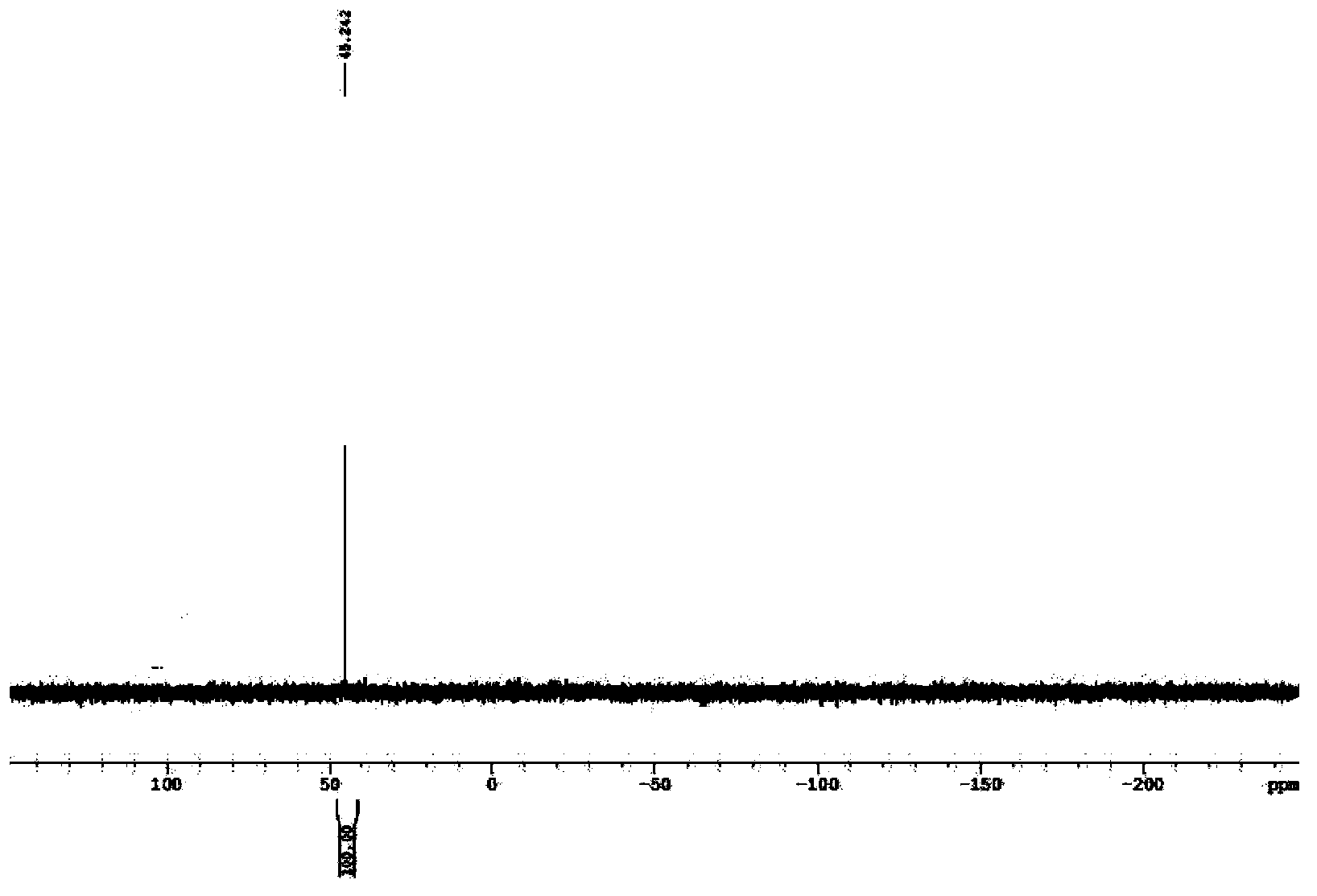

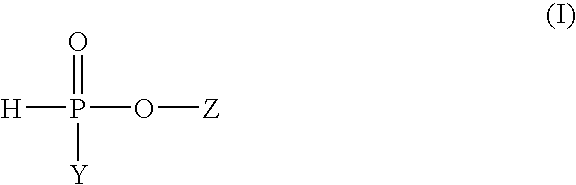

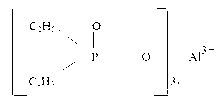

Preparation method of dialkyl hypophosphite

InactiveCN102050835AHigh purityAvoid it happening againGroup 5/15 element organic compoundsPhosphorous acidOrganic solvent

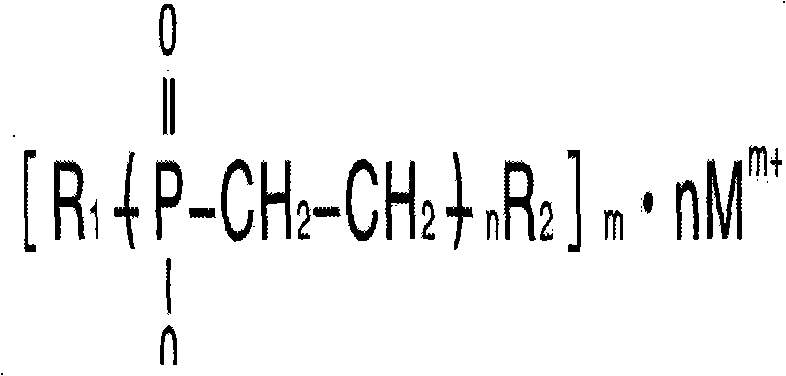

The invention discloses a preparation method of dialkyl hypophosphite. The structure of the dialkyl hypophosphite is disclosed as a Formula (I). The preparation method of the dialkyl hypophosphite comprises the following steps: preparing a Grignard reagent from alkylogen, magnesium powder and organic solvent, preparing dialkyl phosphorus oxide from the Grignard reagent and diethylester phosphite,carrying out reaction on the dialkyl phosphorus oxide and an oxidant, acidifying to obtain a dialkyl phosphinic acid solution, and carrying out reaction on the dialkyl phosphinic acid solution and a metal salt to obtain the corresponding dialkyl hypophosphite. The preparation method of dialkyl hypophosphite has the advantages of high yield and simple synthesis technique, is convenient to operate,greatly lowers the production cost, simplifies the production equipment and enhances the safety of the production process.(I).

Owner:GUANGZHOU KINGSKY MATERIAL

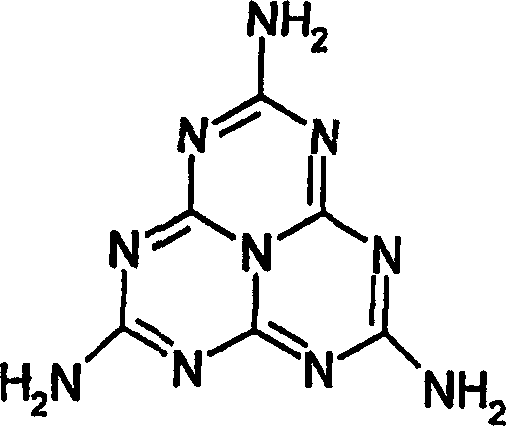

Antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and preparation method thereof

InactiveCN103351618AGood modification effectImprove antistatic performanceZinc borateAntistatic agent

The invention relates to an antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and a preparation method thereof. The fire-retardant master batch is composed of following components in parts by weight: 25 to 50 parts of PA, 15 to 30 parts of alkyl phosphinate fire-retardant, 15 to 30 parts of melamine polyphosphate fire retardant, 8 to 15 parts of zinc borate fire retardant, 4 to 6 parts of CTI improver, 1 to 1.5 parts of antistatic agent, 3 to 8 parts of flexibilizer, 0.5 to 1 part of coupling agent, 0.7 to 1.5 parts of lubricant, and 0.3 to 1 part of anti-oxidant. The sum of the weight ratio of components mentioned above is 100 wt%. The fire-retardant master batch is used to produce fire-retardant enhanced and modified nylon, meets standards of the United States underwriters laboratories (UL)-941.6mm and a higher V-0 grade, simultaneously achieves that glowing wire temperature (GWIT) is equal to or larger than 750 DEG C and the CTI value is equal to or larger than 600 V, also has a antistatic performance, meets European Union RoHS, International Electrotechnical Commission (IEC) halogen-free and Reach rule requirements, is easy to use and excellent in comprehensive performance, and does not affect color matching.

Owner:GUANGDONG WAYLAM ENG PLASTICS

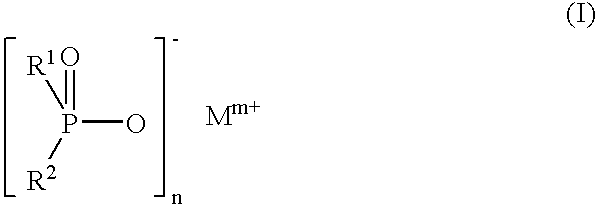

Resin Composition Excellent in Flame Retardance

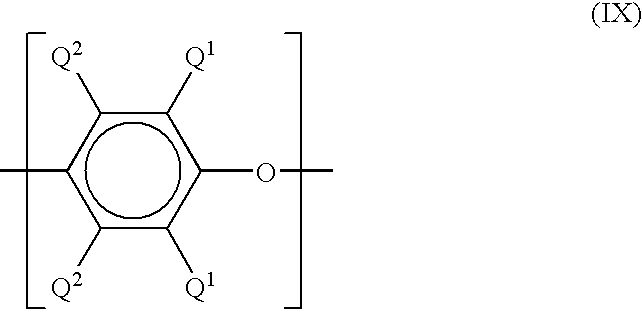

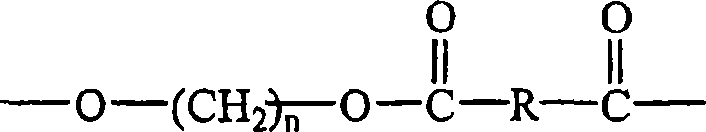

InactiveUS20090275682A1Improve flame retardant performanceImprove impact resistanceGroup 5/15 element organic compoundsEtherPolyamide

The present invention relates to a resin composition containing (A) a polyamide having a viscosity number (as measured in the 96% sulfuric acid according to ISO 307 (1997)) of from 50 ml / g to 250 ml / g; (B) a polyphenylene ether; and (C) a phosphinate represented by a particular formula. The resin composition according to the present invention is excellent in flame retardancy, impact resistance and thin-wall moldability and can significantly suppress gas generation during the molding process and substantially inhibit the generation of deposits on a mold during injection molding. As a result, a molded product thereof excellent in surface appearance can be provided.

Owner:ASAHI KASEI CHEM CORP

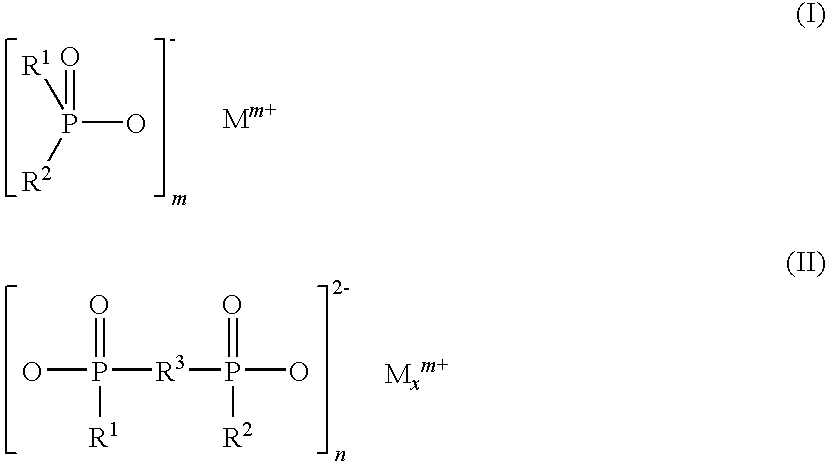

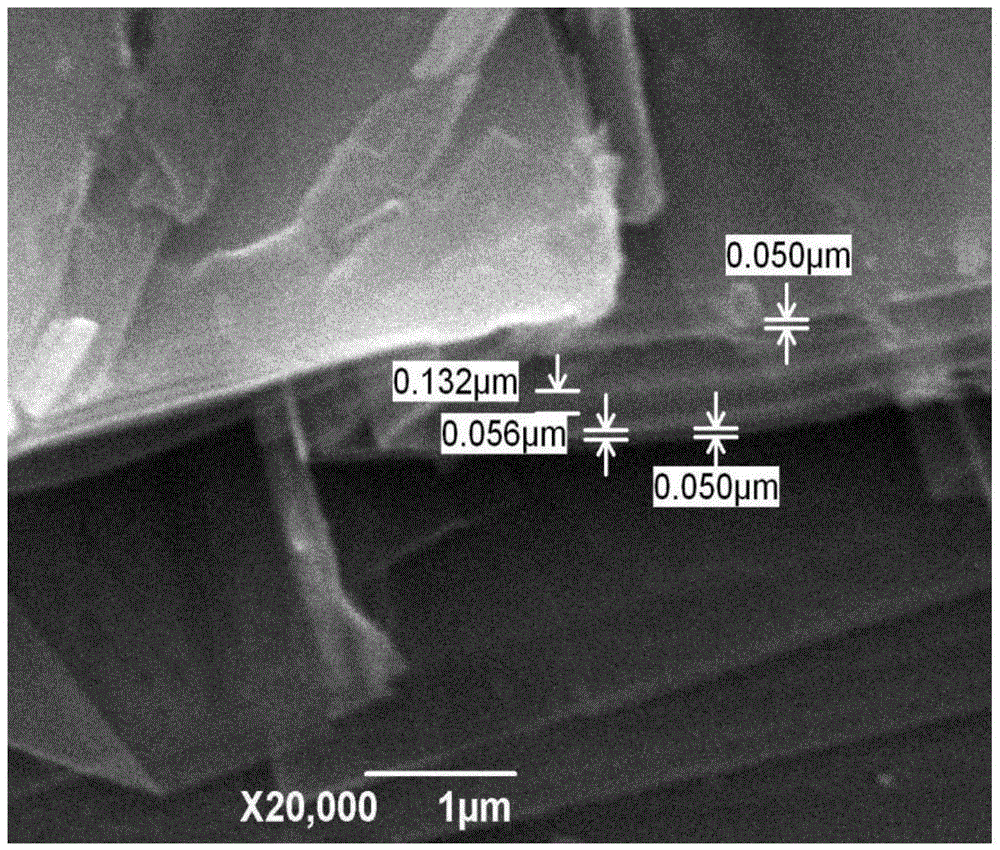

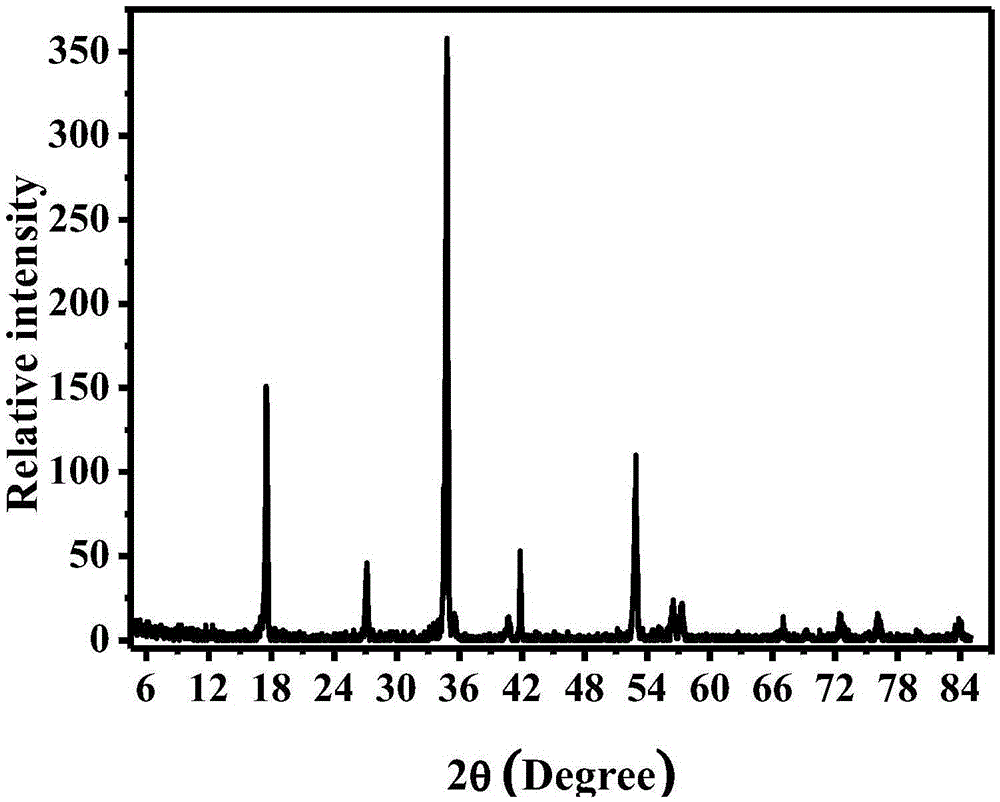

Black phosphorus and phosphinidene preparing methods

The invention relates to black phosphorus and phosphinidene preparing methods. According to the black phosphorus preparing method, tin tetraiodide, tin and red phosphorus are used as raw materials to prepare black phosphorus through reaction. According to the phosphinidene preparing method, the prepared black phosphorus is treated in N-methyl pyrrolidone, absolute ethyl alcohol or N-cyclohexyl-2-pyrrolidone for a proper period of time under the stirring and ultrasonic condition at 20-50 DEG C. Reasonable preparing raw materials and reaction conditions are adopted, and synthesis can be achieved within 21-32 h only. Few-layer black phosphorus is prepared successfully by means of the liquid-phase stripping method. According to the preparing methods, the technology is simple, raw materials are cheap, and repeatability is high.

Owner:NORTHWEST UNIV(CN)

Fireproof composition based on thermoplastic matrix

The present invention relates to a thermoplastic flame retardant composition comprising a specific flame retardant system based on phosphinates and melamine derivatives. Such compositions are especially useful in the preparation of articles for use in the field of electrical or electronic connectors.

Owner:POLYAMIDE HIGH PERFORMANCE

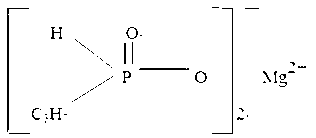

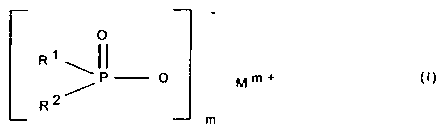

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172668AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsOrganic solventPhosphate

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: organic solvent-water is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, organic solvent-water is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, the reaction period is short, obtained monoalkyl / dialkyl phosphinate can be precisely controlled, a total yield is high, and product purity is high. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:GUANGZHOU KINGSKY MATERIAL

Flame-retardant polyamide composition

InactiveUS20110257313A1Improve mechanical propertiesImprove thermal stabilityGroup 5/15 element organic compoundsThermoplasticHalogen

A halogen-free flame-retardant polyamide composition which generates no halogen compound during combustion. The composition has excellent thermal stability during high-temperature molding and is capable of showing high flame retardancy when burned. The composition is effective in inhibiting steel materials, such as the screw or cylinder of an extruder or molding machine, from corroding or wearing. The flame-retardant polyamide composition in a preferred embodiment comprises 20-60 mass % polyamide resin (A), 5-40 mass % thermoplastic resin (B) other than (A), 3-15 mass % flame retardant (C) having no halogen radicals in the molecule, and 0-50 mass % reinforcement (D), wherein the thermoplastic resin (B) satisfies the UL94V-0 standards, the flame retardant (C) is a phosphinic acid salt compound, and the sum of the thermoplastic resin (B) and the flame retardant (C) is 16-45 mass %.

Owner:MITSUI CHEM INC

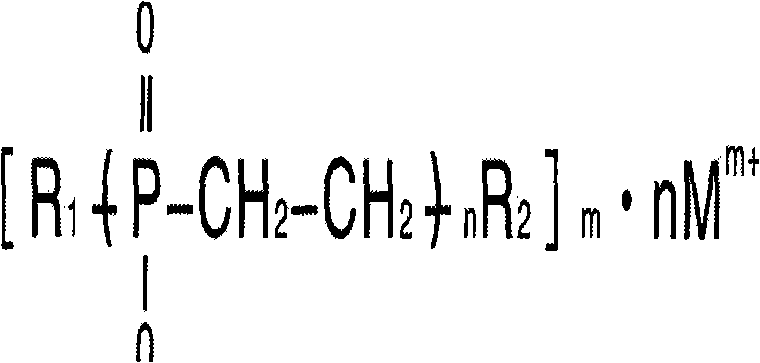

Reinforced polyester compositions, methods of manufacture, and articles thereof

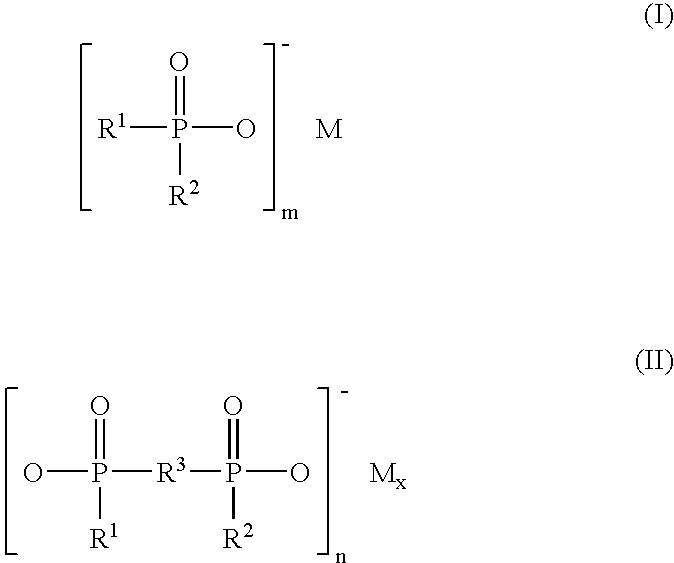

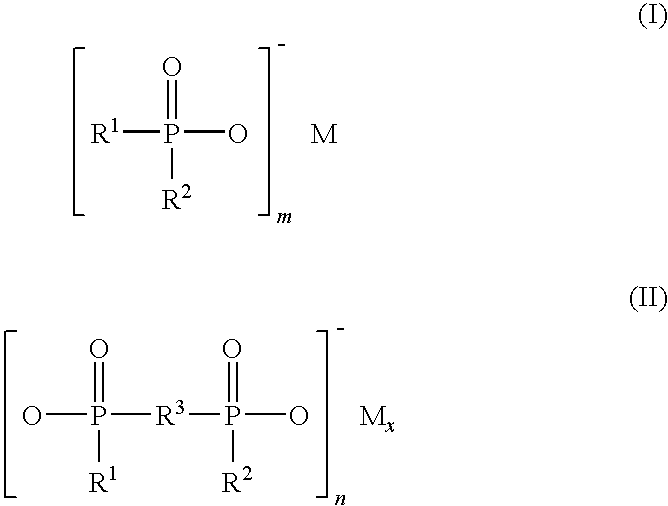

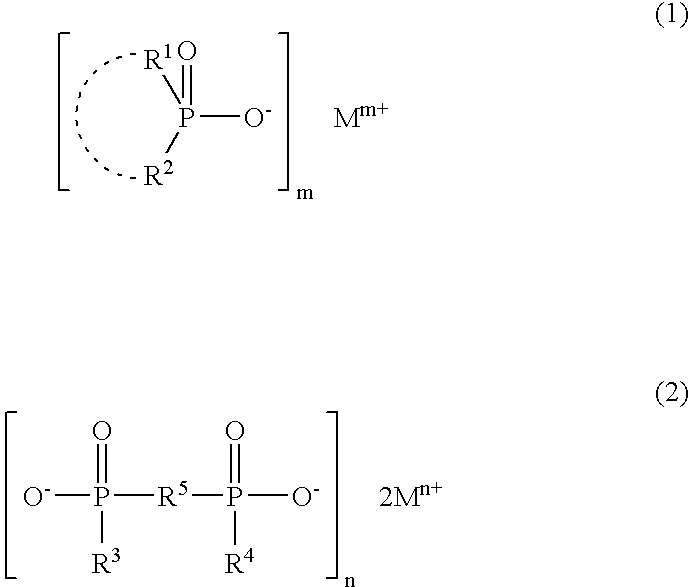

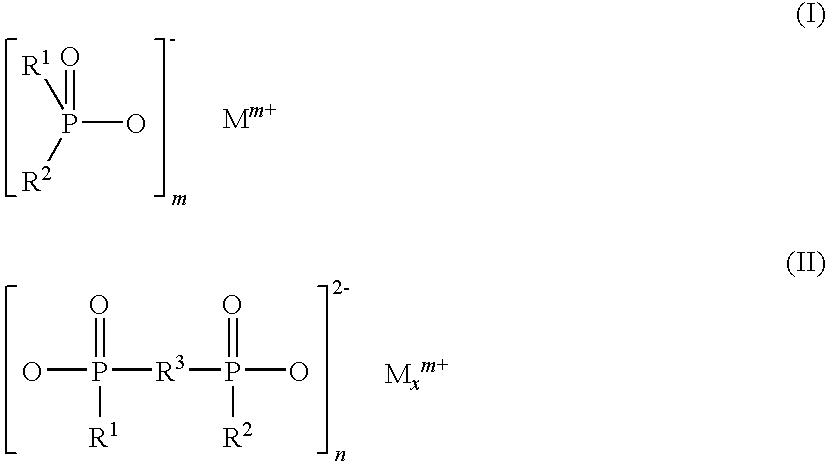

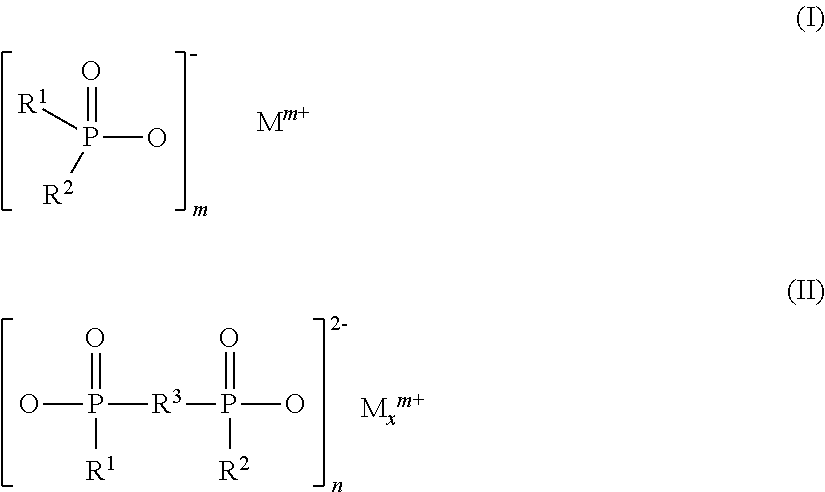

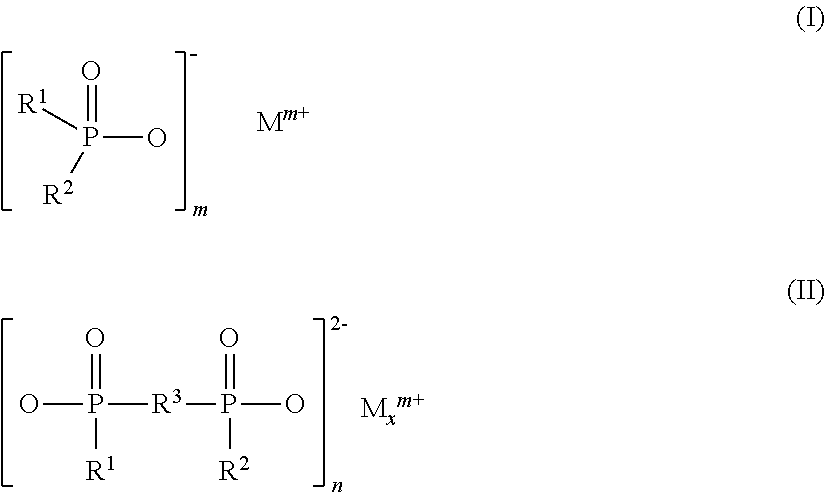

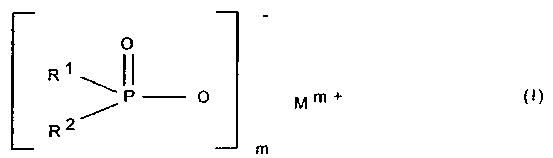

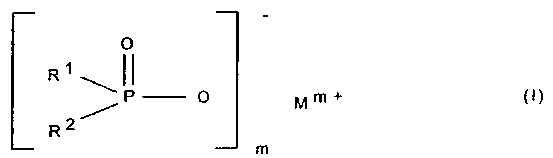

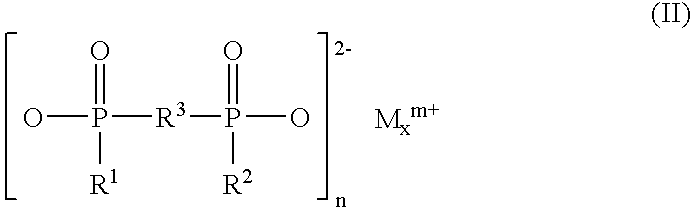

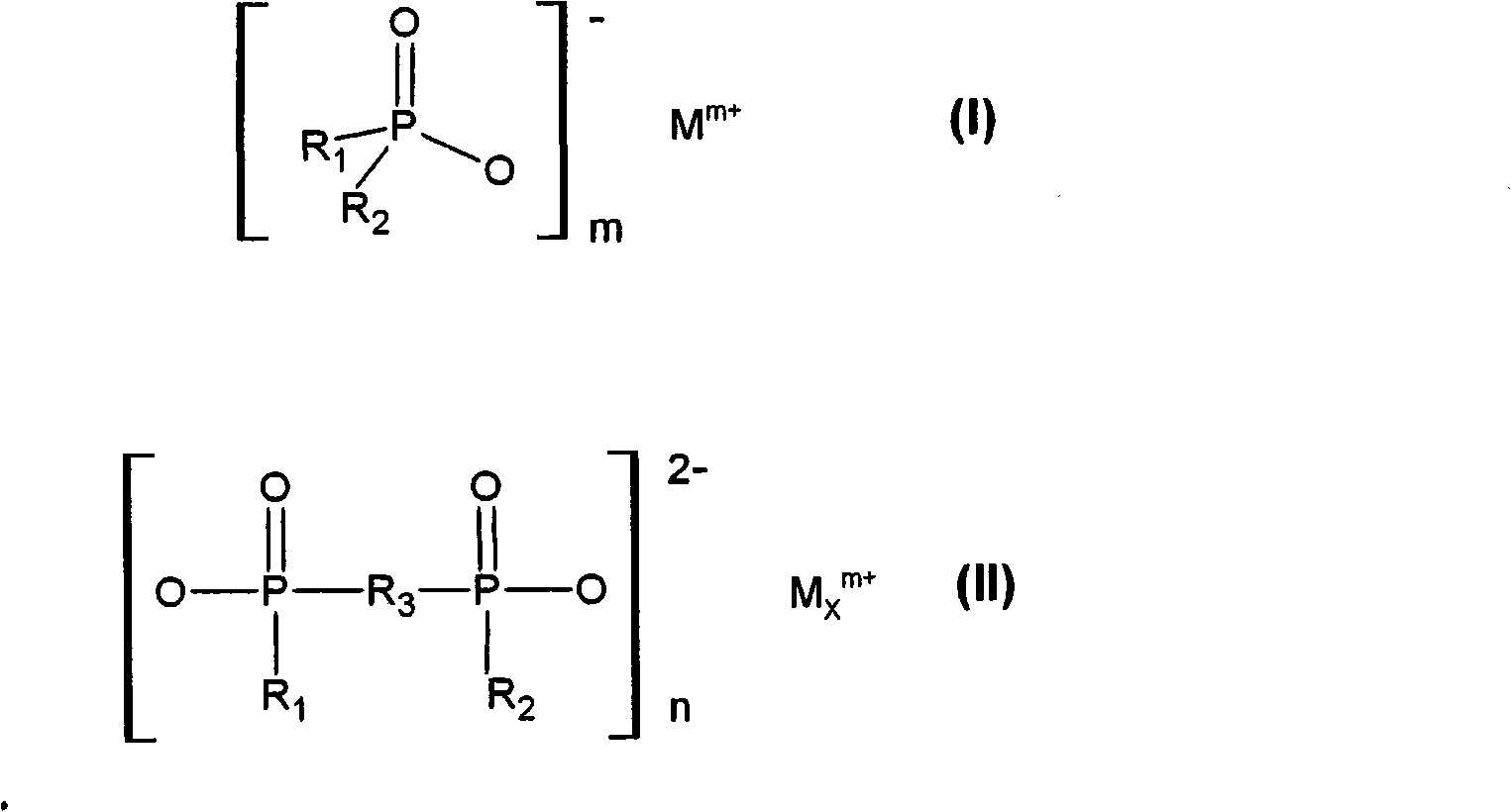

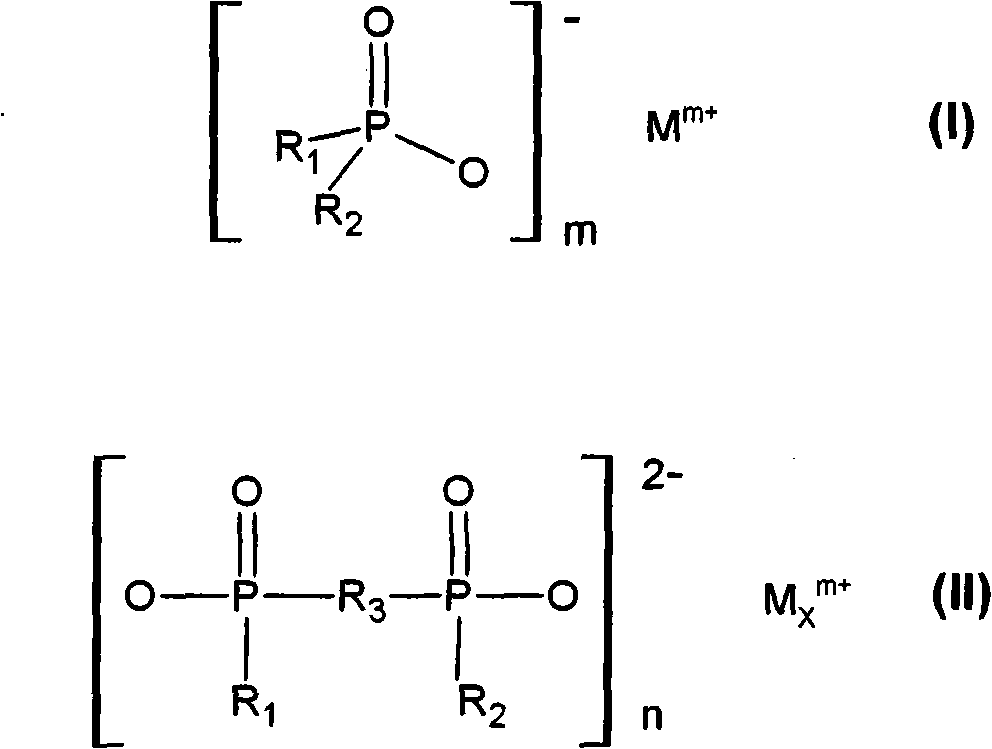

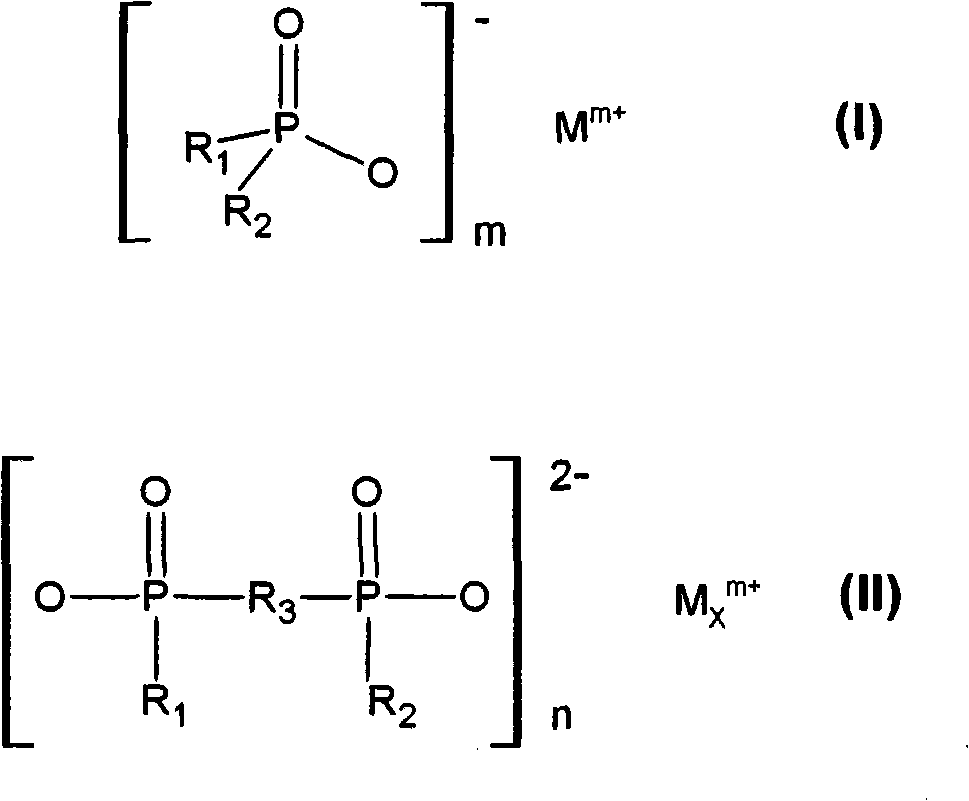

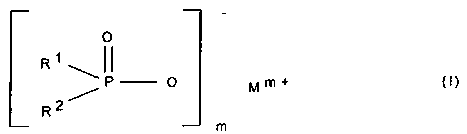

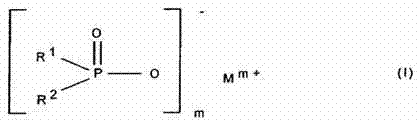

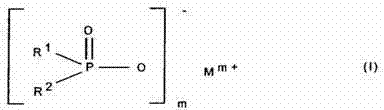

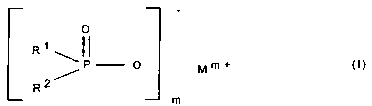

A composition comprises, based on the total weight of the composition: from 20 to 90 wt. % of a polyester component comprising a poly(butylene terephthalate);from 5 to 35 wt. % of a flame retardant phosphinate of the formula (I)[(R1)(R2)(PO)—O]−mMm+ (I)a flame retardant diphosphinate of the formula (II)[(O—POR1)(R3)(POR2—O)]2−nMm+x (II),and / or a flame retardant polymer derived from the flame retardant phosphinate of the formula (I) or the flame retardant diphosphinate of the formula (II); from 1 to 25 wt. % of a melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, and / or melamine phosphate; from greater than zero to 50 wt. % of a glass fiber having a non-circular cross-section; and from 0 to 5 wt. % of an additive selected from the group consisting of a mold release agent, an antioxidant, a thermal stabilizer, an antioxidant, and a UV stabilizer; wherein the components have a combined total weight of 100 wt. %.

Owner:SABIC GLOBAL TECH BV

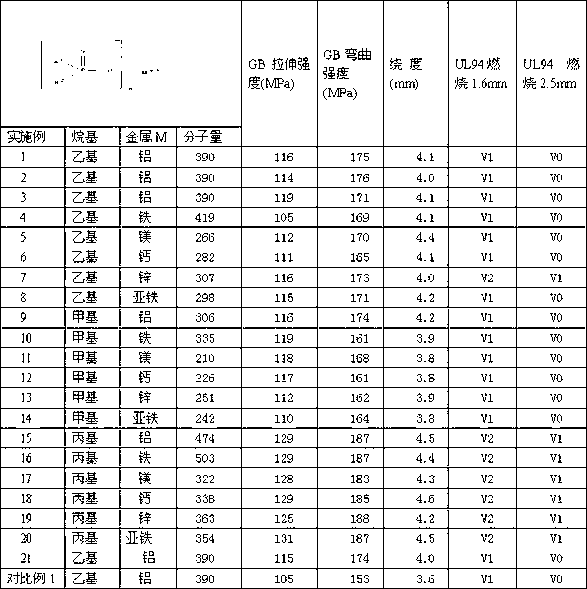

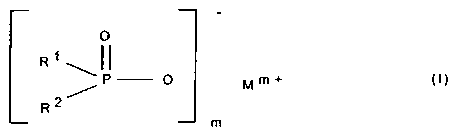

Preparation method and application of dialkyl phosphinate with high density and large diameter

InactiveCN103102367ALarge particle sizeHigh bulk densityGroup 5/15 element organic compoundsHigh densityEthyl group

The invention discloses a preparation method and application of dialkyl phosphinate with high density and large diameter. The method comprises steps of: a) adding an alkali compound aqueous solution into a dialkyl phosphinic acid and / or dialkyl phosphinic acid alkali metal salt aqueous solution, and adjusting the solution to an alkaline state to obtain a dialkyl phosphinate aqueous solution under alkaline conditions; b) reacting the metal compound aqueous solution with the dialkyl phosphinate aqueous solution under alkaline conditions; and c) neutralizing the solution with acid to obtain the dialkyl phosphinate shown such as a formula (I). R1, R2 are the same or different, and represent methyl, ethyl, butyl, pentyl, cyclopentyl, cyclohexyl or octyl; M represents Mg, Ca, Al, Fe, Zn, Sb, Sn, Ge, Ti, Zr or Sr; and m is 2-4. The prepared dialkyl phosphinate has large diameter and high bulk density; the method has simple process, convenient operation and easy product packaging, and can greatly reduce dust pollution during the production process; and the product can be used as an environment-friendly, efficient, halogen-free flame retardant in polymer materials.

Owner:ZHUHAI WANTONG CHEM

Flame-Retardant Resin Composition

InactiveUS20070054992A1Improve flame retardant performanceSmall size changeGroup 5/15 element organic compoundsO-Phosphoric AcidPolyamide

There is provided a flame-retardant resin composition which is excellent in flame retardancy and excellent in low water-absorbing property and exhibits a small dimensional change and a small decrease in insulating properties. A flame-retardant resin composition containing: (A) an aliphatic polyamide resin; (B) an aromatic polyamide resin; (C) a flame retardant containing (c1) a phosphinic acid salt represented by the following formula (I) and / or (c2) a diphosphinic acid salt represented by the following formula (II) and / or a polymer containing at least one of these (c1) and (c2) as a component C1 and containing (c3) a melamine condensation product and / or (c4) a reaction product of melamine with phosphoric acid and / or (c5) a reaction product of a melamine condensation product with phosphoric acid and / or a mixture containing at least two of these (c3) to (c5) as a component C2; and (D) an inorganic filler.

Owner:UBE IND LTD

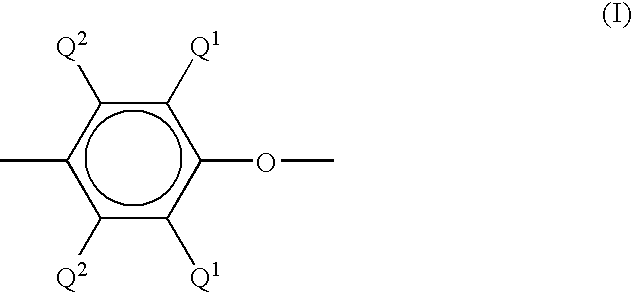

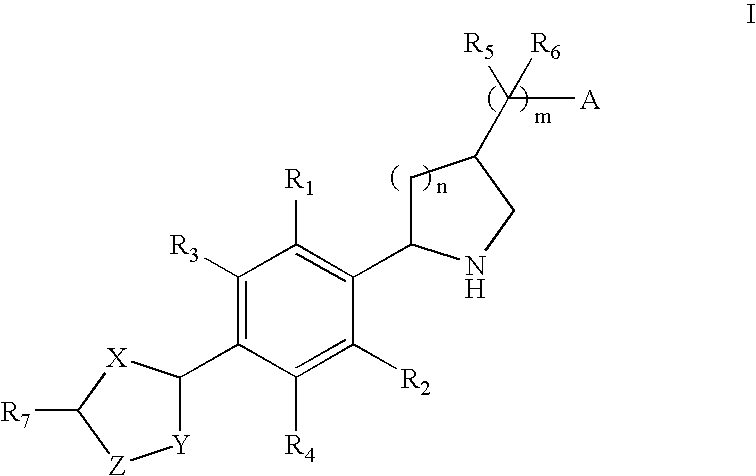

Thyroid receptor ligands

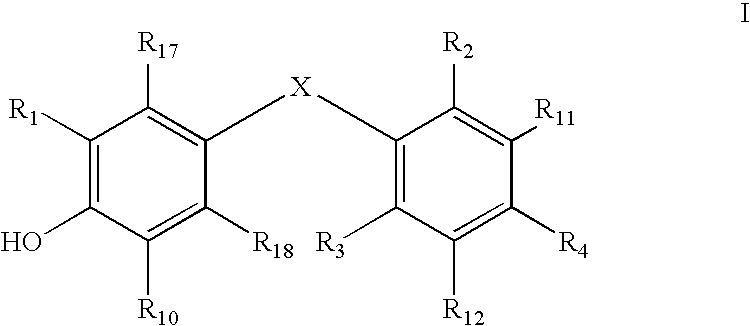

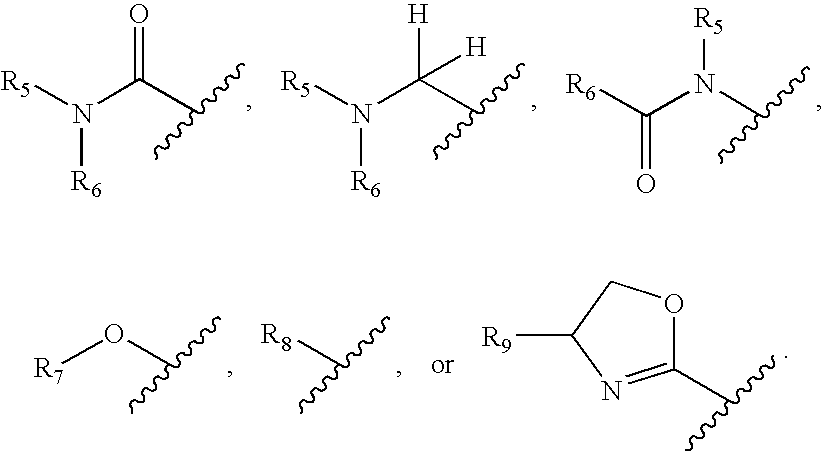

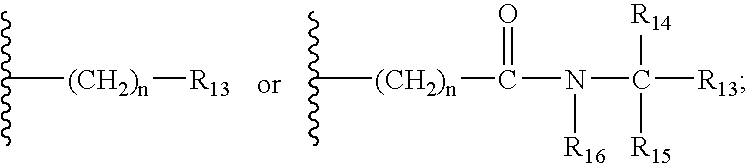

Thyroid receptor ligands are provided which have the general formula I wherein: R1 is R2 and R3 are the same or different and are hydrogen, halogen, alkyl of 1 to 4 carbons or cycloalkyl of 3 to 5 carbons, provided that at least one of R2 and R3 is other than hydrogen; R4 is R5 and R6 are the same or different and are selected from hydrogen, aryl, heteroaryl, alkyl, cycloalkyl, aralkyl or heteroaralkyl. R7 is aryl, heteroaryl, alkyl, aralkyl, or heteroaralkyl; R8 is aryl, heteroaryl, or cycloalkyl; R9 is R7 or hydrogen; R10 is hydrogen, halogen, cyano or alkyl; R11 and R12 are each independently selected from the group consisting of hydrogen, halogen, alkoxy, hydroxy (—OH) cyano, and alkyl; R13 is carboxylic acid (COOH) or esters thereof, phosphonic and phosphinic acid or esters thereof, sulfonic acid, tetrazole, hydroxamic acid, thiazolidinedione, acylsulfonamide, or other carboxylic acid surrogates known in the art; R14 and R15 may be the same or different and are selected from hydrogen and alkyl, or R14 and R15 may be joined together forming a chain of 2 to 5 methylene groups [—(CH2)m-, m=2, 3, 4 or 5], thus forming 3- to 6-membered cycloalkyl rings; R16 is hydrogen or alkyl of 1 to 4 carbons; R17 and R18 are the same or different and selected from hydrogen, halogen and alkyl; n is 0 or an integer from 1 to 4; X is oxygen (—O—), sulfur (—S—), sulfonyl (—SO2—), sulfenyl (—SO—) selenium (—Se—), carbonyl (—CO—), amino (—NH—) or methylene (—CH2-); wherein the substituents are as described herein. In addition, a method is provided for preventing, inhibiting or treating diseases or disorders associated with metabolism dysfunction or which are dependent upon the expression of a T3 regulated gene, wherein a compound as described above is administered in a therapeutically effective amount.

Owner:BRISTOL MYERS SQUIBB CO

Flame resistant semiaromatic polyamide resin composition and articles therefrom

Disclosed are polyamide compositions containing a polyamide component comprising 20 to 100 weight percent of at least one semiaromatic polyamide, non-halogenated flame retardant comprising one or more of a phosphinate, a disphosphinate and polymers thereof, and zinc borate that have reduced corrosion effects on melt processing equipment.

Owner:EI DU PONT DE NEMOURS & CO

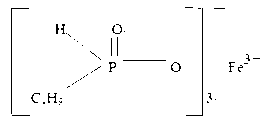

Preparation method of dialkylphosphinate metal salt

InactiveCN103172663ASmall particle sizeImprove fluidityGroup 5/15 element organic compoundsPhosphinic AcidsPhosphinidene

The invention discloses a preparation method of a dialkylphosphinate metal salt. The preparation method comprises the following steps: a) adding a coupling agent into a water solution of dialkyl phosphinic acid and / or a dialkylphosphinate alkali metal salt to get the water solution of dialkyl phosphinic acid and / or the dialkylphosphinate alkali metal salt containing the coupling agent; and b) adding the coupling agent or not adding the coupling agent into a mixture of a metal compound and water, and further reacting with the water solution of dialkyl phosphinic acid and / or the dialkylphosphinate alkali metal salt containing the coupling agent to generate the dialkylphosphinate metal salt. The dialkylphosphinate metal salt obtained by the preparation method disclosed by the invention has small particle size and good flowability; and furthermore, when the particle size is less than 90 mu m, in particular to 40 mu m, the tap density can still above 600g / L, and the problems that such flame retardants are easy to raise dust during the feeding process and less prone to uniformly mixing with resin can be well solved. The preparation method disclosed by the invention has the advantages of simple process and convenience in operation, and the coupling agent is low in price and easy to obtain; and simultaneously, production equipment is simplified and production cost is reduced.

Owner:ZHUHAI WANTONG CHEM

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172670AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsOrganic solventPhosphate

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: water is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, water is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, hypophosphite is directly adopted as a raw material, and the monoalkyl / dialkyl phosphinate is obtained with a one-step method. The reaction period is short, a total yield is high, product purity is high, process flow is simple, no organic solvent or other solvent is adopted, and no subsequent processing is needed. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:ZHUHAI WANTONG CHEM

Dialkyl phosphinic acid salt and preparation method thereof

InactiveCN103073575AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsBenzenePhosphoric acid

The invention discloses a dialkyl phosphinic acid salt with the following structural formula (I). R1 and R2 are the same or different, and represent C2-C6 alkyls; secondary M represents Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr or Sr; m equals to 1-4; and mole percent of a telomer is 0.1-10mol%. The preparation method comprises steps of: a) reacting hypophosphorous acid with high concentration with olefin under the effect of an initiator by using benzene as a solvent to obtain a dialkyl phosphinic acid-organic phase solution; b) removing the organic solvent by water extraction or vacuum distillation, and diluting with water to obtain a dialkyl phosphinic acid aqueous solution; c) neutralizing with an aqueous solution of an alkaline compound to obtain a dialkyl phosphinic acid alkali metal salt aqueous solution; and d) reacting the dialkyl phosphinic acid alkali metal salt aqueous solution with a metal compound aqueous solution to obtain dialkyl phosphinic acid salt. The method provided by the invention employs hypophosphorous acid with high concentration as a raw material and benzene as the solvent to obtain a product containing part of telomer, has a short reaction period only requiring 4-6 h to complete the process, and has a high total yield; the process is simple; and the organic solvent can be recycled.

Owner:GUANGZHOU KINGSKY MATERIAL

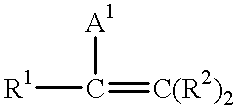

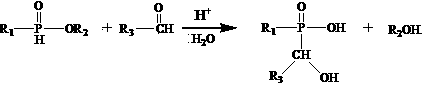

Method for producing phosphorus-containing α-keto acid

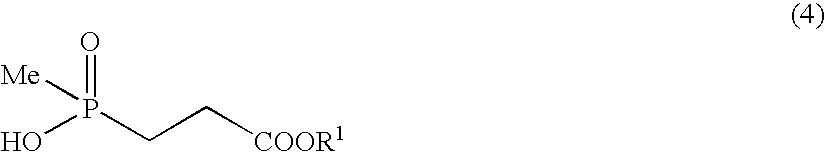

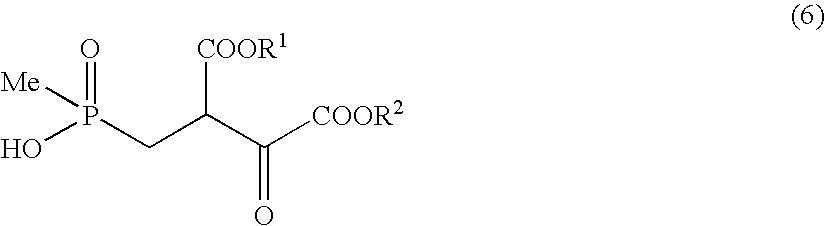

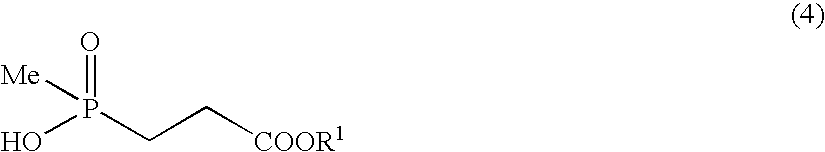

InactiveUS8017797B2Increase productionEfficient productionOrganic compound preparationGroup 5/15 element organic compoundsButyratePhosphinidene

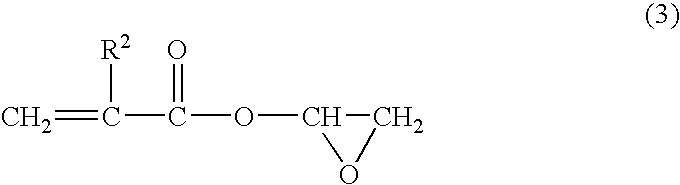

A method for efficiently producing 4-(hydroxymethylphosphinyl)-2-oxobutanoic acid, useful as a production intermediate of herbicide L-AMPB. The method comprises using a compound represented by the below formula (4): (4) where R1 represents a C1-4 alkyl group, arylmethyl group, or substituted arylmethyl group.

Owner:MEIJI SEIKA KAISHA LTD

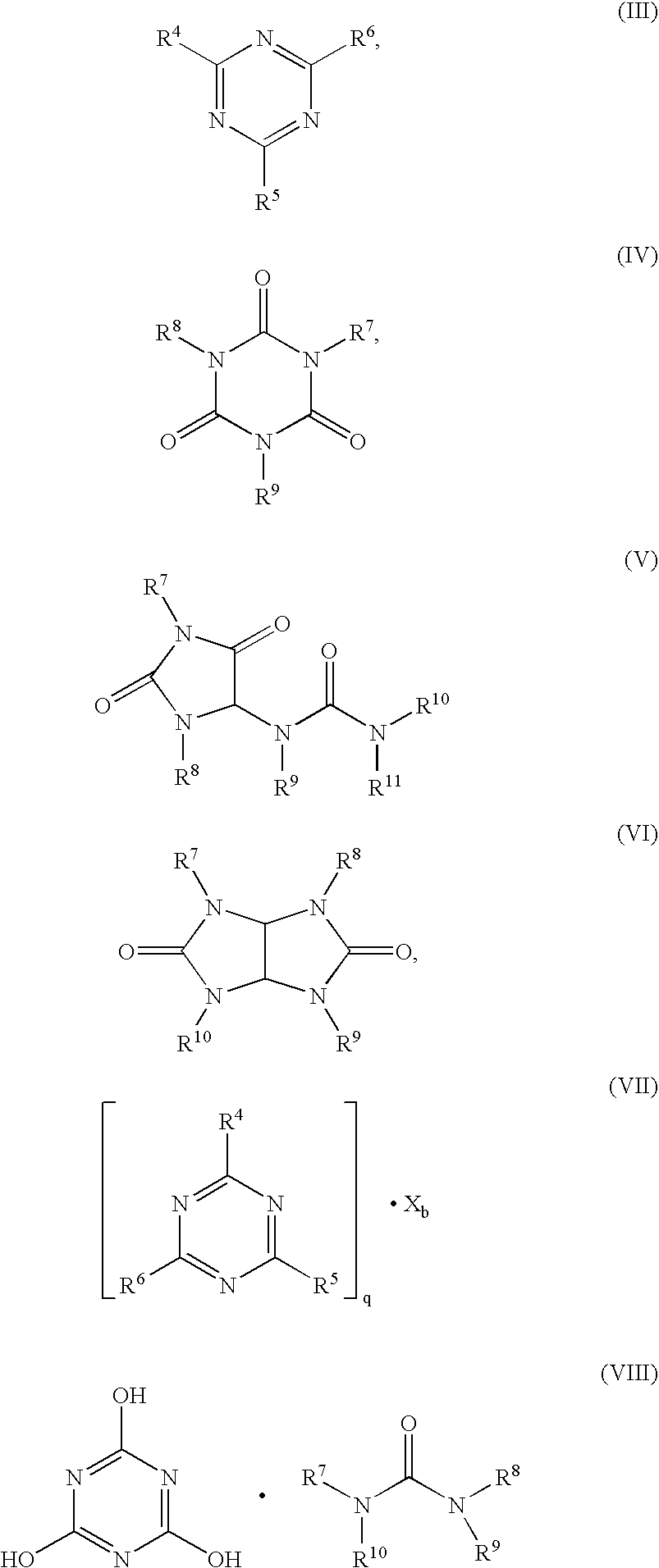

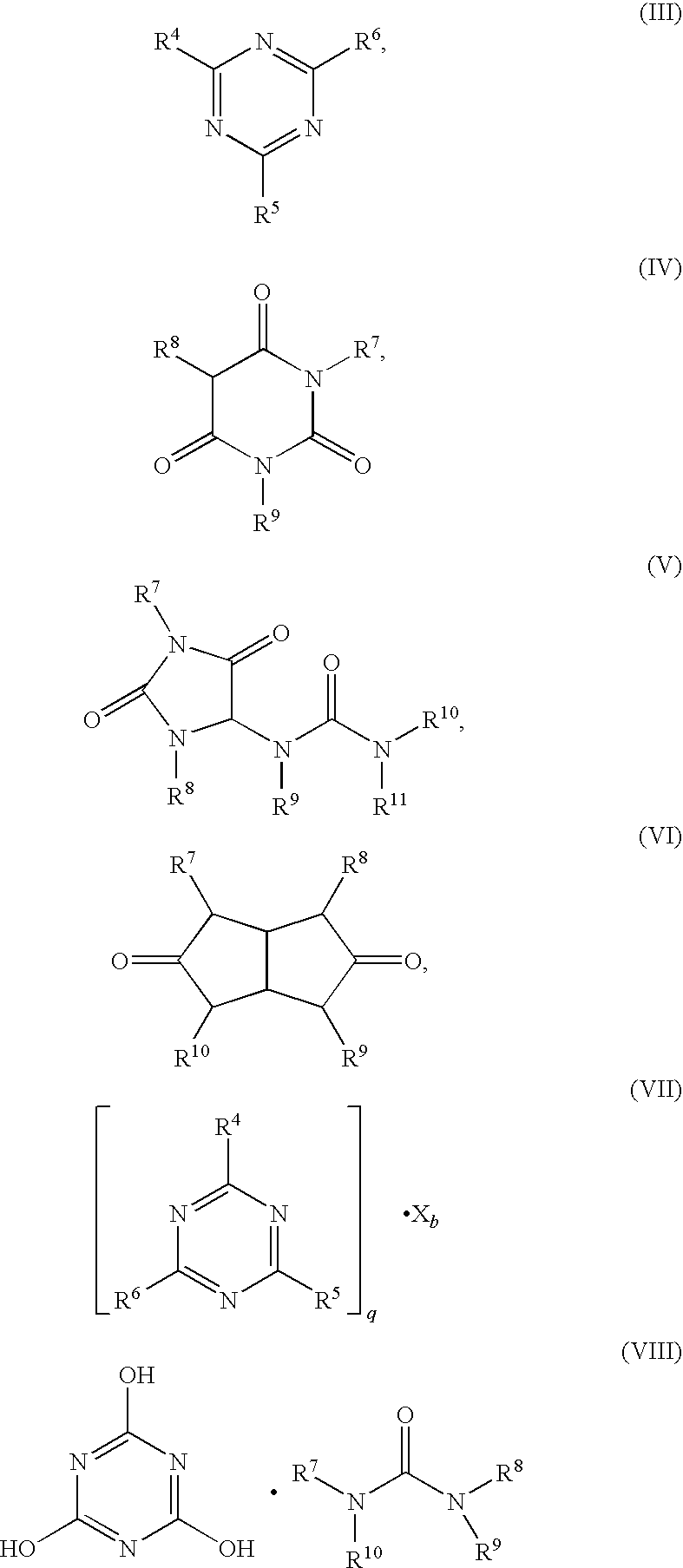

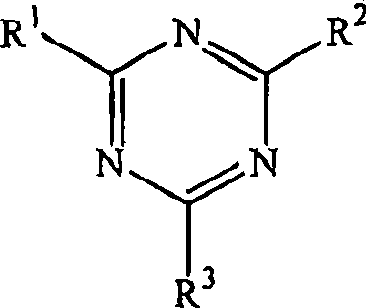

Flame-retardant polyester composition

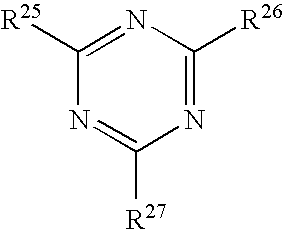

A composition, comprising: a poly(butylene terephthalate); a nitrogen-containing flame retardant selected from the group consisting of triazines, guanidines, cyanurates, isocyanurates, and mixtures comprising at least one of the foregoing nitrogen-containing flame retardants; a phosphinates or diphosphinates; and a charring polymer.

Owner:SABIC GLOBAL TECH BV

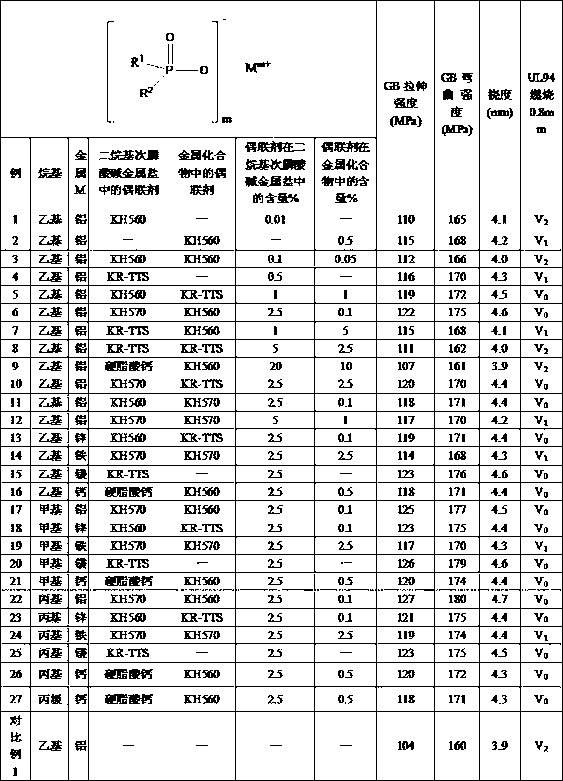

Alkyl phosphinate polymer and preparation method and application thereof

The invention relates to an alkyl phosphinate polymer and a preparation method and application thereof. The method comprises the following steps of: filling a mixture of hypophosphorous acid or phosphinate and water or acetic acid into a pressure reactor with a jacket; when the mixture is heated to between 70 and 110 DEG C, adding alkyne into the pressure reactor through a pressure-reducing valvetill the mixture in the pressure reactor is saturated; uniformly adding aqueous solution of free radical initiator into the obtained mixture with continuous stirring till reaching the required alkynequantity, and then switching the alkyne into olefin; adding the olefin into the pressure reactor through the pressure-reducing valve till the mixture in the pressure reactor is saturated, uniformly adding a catalyst into the mixture, reacting the mixture for 8 to 12 hours, reducing the pressure of the pressure reactor, and cooling the mixture to 80 DEG C; and adding a metal compound into the pressure reactor to perform reaction, centrifuging the obtained solid, washing the solid by using water, and drying the solid in vacuum to obtain the alkyl phosphinate polymer. The invention also relates to the application of the alkyl phosphinate polymer serving as a flame retardant, a flame retardant composition and a flame-retardant polymer molding composition.

Owner:SHANGHAI HUIHAI CHEM TECH

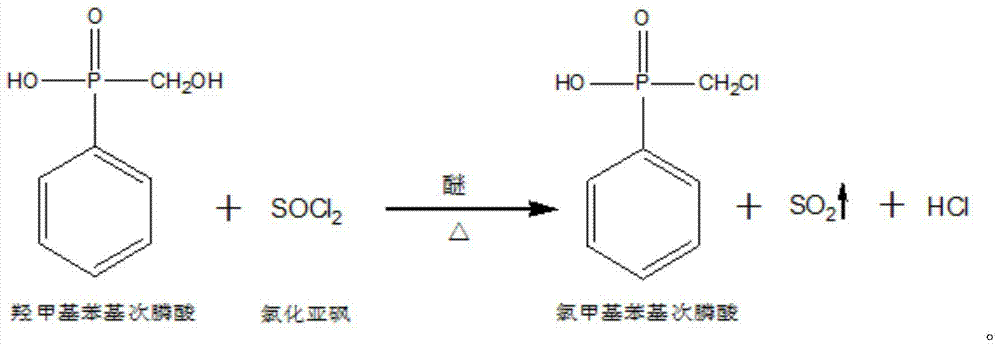

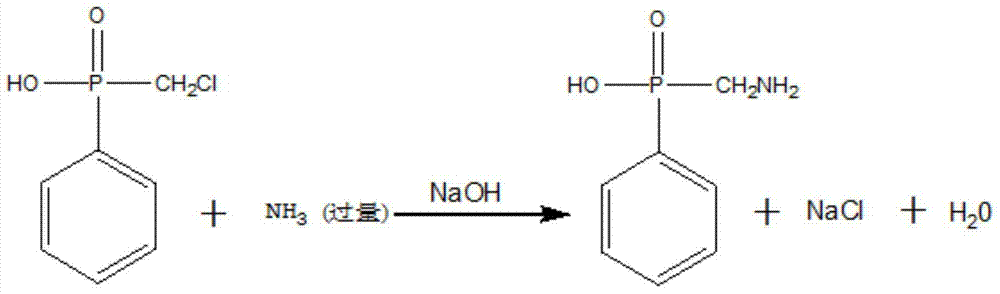

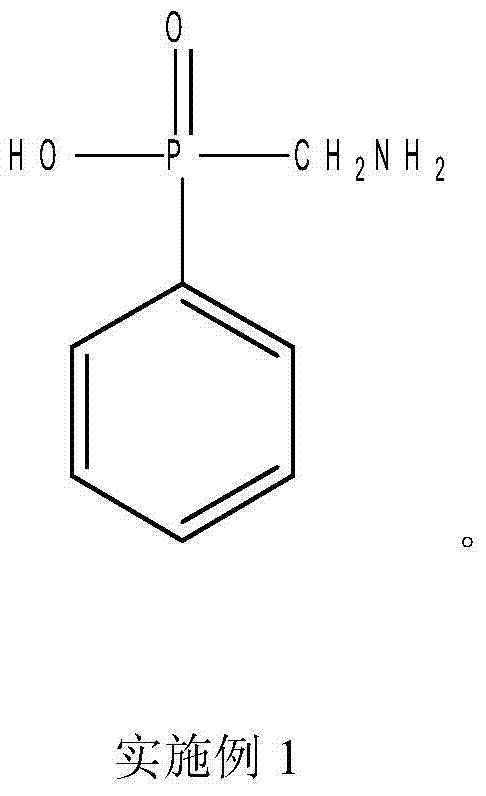

Flame-retardant nylon 6 and preparation method thereof

The invention relates to flame-retardant nylon 6 and a preparation method thereof. The flame-retardant nylon 6 is prepared by performing polymerization on a nylon polymerization monomer namely caprolactam, aminomethyl phenyl phosphinic acid and a polymer catalyst. The preparation method comprises the following steps: performing heating reaction on hydroxymethyl phenyl phosphinic acid, sulfoxide chloride and ether in a reaction kettle according to a certain mole ratio, putting the prepared chloromethyl phenyl phosphinic acid into a sodium hydroxide solution, and introducing ammonia gas into the sodium hydroxide solution to perform ammoniation reaction so as to prepare aminomethyl phenyl phosphinic acid; and performing polymerization on the nylon polymerization monomer namely caprolactam, aminomethyl phenyl phosphinic acid and the polymer catalyst to obtain the flame-retardant nylon 6. According to the flame-retardant nylon 6 provided by the invention, the aminomethyl phenyl phosphinic acid is added into a polymerization system of the flame-retardant nylon 6 to ensure that a flame retardant is perfectly combined with nylon 6, and the flame retardant cannot generate negative influence on the mechanical properties of the nylon 6, and can ensure that the nylon 6 has a very good flame retardant effect under the condition that very little flame retardant is added.

Owner:泰索新材料科技(杭州)有限公司

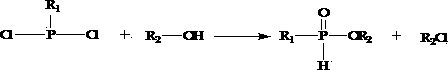

Preparation method of monohydroxy dialkyl phosphinic acid metal salt fire retardant

InactiveCN103435643AAvoid dangerNovel synthetic routeGroup 5/15 element organic compoundsPhosphoniumPhosphoric acid

The invention discloses a preparation method of a monohydroxy dialkyl phosphinic acid metal salt fire retardant. The preparation method comprises the following steps: 1) performing reaction on alkyl phosphonium dichloride and alcohol to obtain monoalkyl phosphonate; 2) in the presence of acid and water, performing reaction on monoalkyl phosphonate obtained from the former step and aldehyde to obtain monohydroxy alkyl phosphinic acid solution; 3) performing reaction on monohydroxy alkyl phosphinic acid solution obtained from the former step and lewis acid in water, generating the monohydroxy dialkyl phosphinic acid metal salt fire retardant solid, separating out solid, washing and drying the solid to obtain the product. According to the preparation method, monosubstituted phosphonium dichloride is taken as a starting material, so that the synthetic route is novel. The risk of using gaseous state raw material such as olefin is avoided. According to the invention, the reaction conditions are mild (normal pressure, and temperature not higher than 100 DEG C); the synthetic steps are few; separate purification is needless; the technology is simple; the production equipment is simplified; the safety of the production process is improved.

Owner:PRESAFER QINGYUAN PHOSPHOR CHEM

Process for the preparation of highly purified, dialkyl phosphinic acids

In a process for the production of dialkylphosphinic acids, especially branched, dialkylphosphinic acids in high purity via the reaction of an alpha olefin with a hypophosphorous acid or a salt thereof, the improvement comprising conducting the reaction in the presence of a stoichiometric excess of the olefin and isolating and purifying the desired dialkylphosphinic acid product by neutralizing the monoalkylphosphinic acid by-product with an aqueous base; removing the aqueous phase in which the neutralized monoalkylphosphinic acid is preferentially solubilized; acidifying the dialkyl product in the organic phase; and isolating the purified product.

Owner:ITALMATCH KEMIKALS SPA

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172669AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsPhosphatePhosphoric acid

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: an organic solvent is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, an organic solvent is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, hypophosphite is directly adopted as a raw material, and the monoalkyl / dialkyl phosphinate is obtained with a one-step method. The reaction period is short, obtained monoalkyl / dialkyl phosphinate can be precisely controlled, a total yield is high, and process floe is simple. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:ZHUHAI WANTONG CHEM

2-(Aryl)Azacyclylmethyl Carboxylates, Sulfonates, Phosphonates, Phosphinates and Heterocycles as S1p Receptor Antagonists

The present invention encompasses compounds of Formula I:as well as the pharmaceutically acceptable salts thereof. The compounds are S1P1 / Edg1 receptor agonists and thus have immunosuppressive, anti-inflammatory and hemostatic activities by modulating leukocyte trafficking, sequestering lymphocytes in secondary lymphoid tissues, and enhancing vascular integrity. The invention is also directed to pharmaceutical compositions containing such compounds and methods of treatment or prevention.

Owner:MERCK SHARP & DOHME CORP

Irradiating crosslinking halogen-free flame-retardant material with non-foaming pipe wall in heating shrinkage and application thereof

ActiveCN103642118AImprove flame retardant performanceReduce dosageFlexible pipesRigid pipesAntioxidantPhosphate

The invention discloses an irradiating crosslinking halogen-free flame-retardant material with a non-foaming pipe wall in heating shrinkage. The irradiating crosslinking halogen-free flame-retardant material comprises the following raw materials in parts by weight: 10-100 parts of ethylene-vinyl acetate copolymer, 0.5-10 parts of organosilicon polymer, 0.1-10 parts of antioxidant, 0.1-50 parts of coated red phosphorus flame retardant, 1-150 parts of aluminium hydroxide and / or magnesium hydrate and / or modified aluminium hydroxide and / or modified magnesium hydrate, 0-50 parts of high molecular weight ammonium polyphosphate (APP) and / or 0-50 parts of phosphate flame retardant and / or 0-50 parts of melamine cyanurate (MCA) and / or 0-50 parts of phosphinates, 0.1-100 parts of carbonate and / or phosphate and / or phosphide and / or calcined clay and / or kaoline and / or clay. The irradiating crosslinking halogen-free flame-retardant material can be applied to a heating shrinkage sleeve and the like, the flame retardant grade achieves the American UL224VW-1 standard, and no halogen is contained.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com