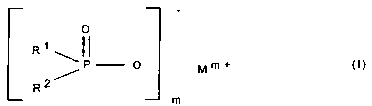

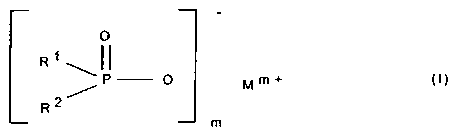

Monoalkyl/dialkyl phosphinate and preparation method thereof

A technology of alkyl phosphinate and mono-alkyl is applied in the field of mono-/di-alkyl phosphinate and its preparation, and can solve the problem that it is difficult to obtain mono-alkyl phosphinate or hypophosphorous acid and the like , to achieve the effect of high yield, low salt content and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

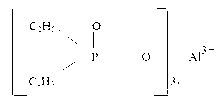

[0047] Embodiment 1: Structure and preparation of aluminum ethyl phosphinate

[0048] Add 444.0g (2mol) of aluminum hypophosphite, 1000mL of toluene and 9.7g (0.04mol) of dibenzoyl peroxide into the high-pressure reactor, seal it, and replace it with nitrogen (0.5MPa) for 5 times while stirring, and then pass ethylene through Adjust the pressure regulator to 2.5MPa and fill it in, heat to 72°C, uniformly heat up to 75°C within 4 hours and inject a solution prepared by 4.8g (0.02mol) dibenzoyl peroxide and 50mL toluene with a metering pump, Then keep the temperature at 75°C for 1 hour, cool and vent to obtain 1538.8 g of aluminum ethylphosphinate-toluene mixed system, which is equivalent to ethylene absorption of 171.0 (equivalent to 101.8% of the theoretical amount).

[0049]The resulting mixed system was filtered, washed once with 1000 mL of hot ethanol, and washed twice with 1000 mL of water, and the resulting filter cake was vacuum-dried at 130°C for 5 hours to obtain alum...

Embodiment 2

[0054] Example 2: Structure and preparation of aluminum diethylphosphinate

[0055] Add 444.2g (2mol) of aluminum hypophosphite, 800mL of toluene and 9.7g (0.04mol) of benzoyl peroxide into the high-pressure reactor, seal it, replace it with nitrogen (0.5MPa) for 5 times while stirring, and then pass ethylene through the regulator Adjust the pressure to 2.5MPa and fill it in, heat to 72°C, uniformly heat up to 75°C within 4 hours and continuously pour in a solution prepared by 4.8g (0.02mol) of benzoyl peroxide and 30mL of toluene with a metering pump; After 4.5 hours, heat up to 105°C, uniformly heat up to 115°C within 4 hours and continuously inject a solution of 11.7g (0.06mol) tert-butyl peroxybenzoate and 100mL toluene with a metering pump; It was kept at ℃ for 1 hour, cooled and evacuated to obtain 1621.2 g of aluminum diethylphosphinate-toluene mixed system, which is equivalent to 345.4 g of ethylene absorption (equivalent to 102.8% of the theoretical amount).

[005...

Embodiment 3

[0062] Example 3: Structure and preparation of aluminum diethylphosphinate

[0063] Add 444.0g (2.00mol) of aluminum hypophosphite and 1000mL of benzene into the high-pressure reactor, seal it, and replace it with nitrogen (0.5MPa) for 5 times while stirring, then adjust ethylene to 2.5MPa through a pressure regulator and fill it in, heat to 105°C, within 11 hours, use a metering pump to evenly inject a solution prepared by 19.4g (0.10mol) tert-butyl peroxybenzoate and 100mL of benzene, and uniformly heat up to 115°C, and then keep it at 115°C for 1 hour , cooled and vented to obtain 1623.3g of aluminum diethylphosphinate-benzene mixed system, which is equivalent to 347.5g of ethylene absorption (equivalent to 103.4% of the theoretical amount).

[0064] The resulting mixed system was filtered, washed once with 1000 mL of ethanol, and then washed twice with 1000 mL of water, and the obtained filter cake was vacuum-dried at 130 °C for 5 hours to obtain aluminum diethylphosphin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com