Rhodococcus ruber and method for preparing 5-cyanovaleramide by utilizing same

A technology of cyanovaleramide and Rhodococcus erythrococcus, which is applied in the field of biochemical engineering, can solve the problems of waste of raw materials, harsh reaction conditions, and many by-products, and achieve the effects of simplified separation and purification process, high catalytic efficiency, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

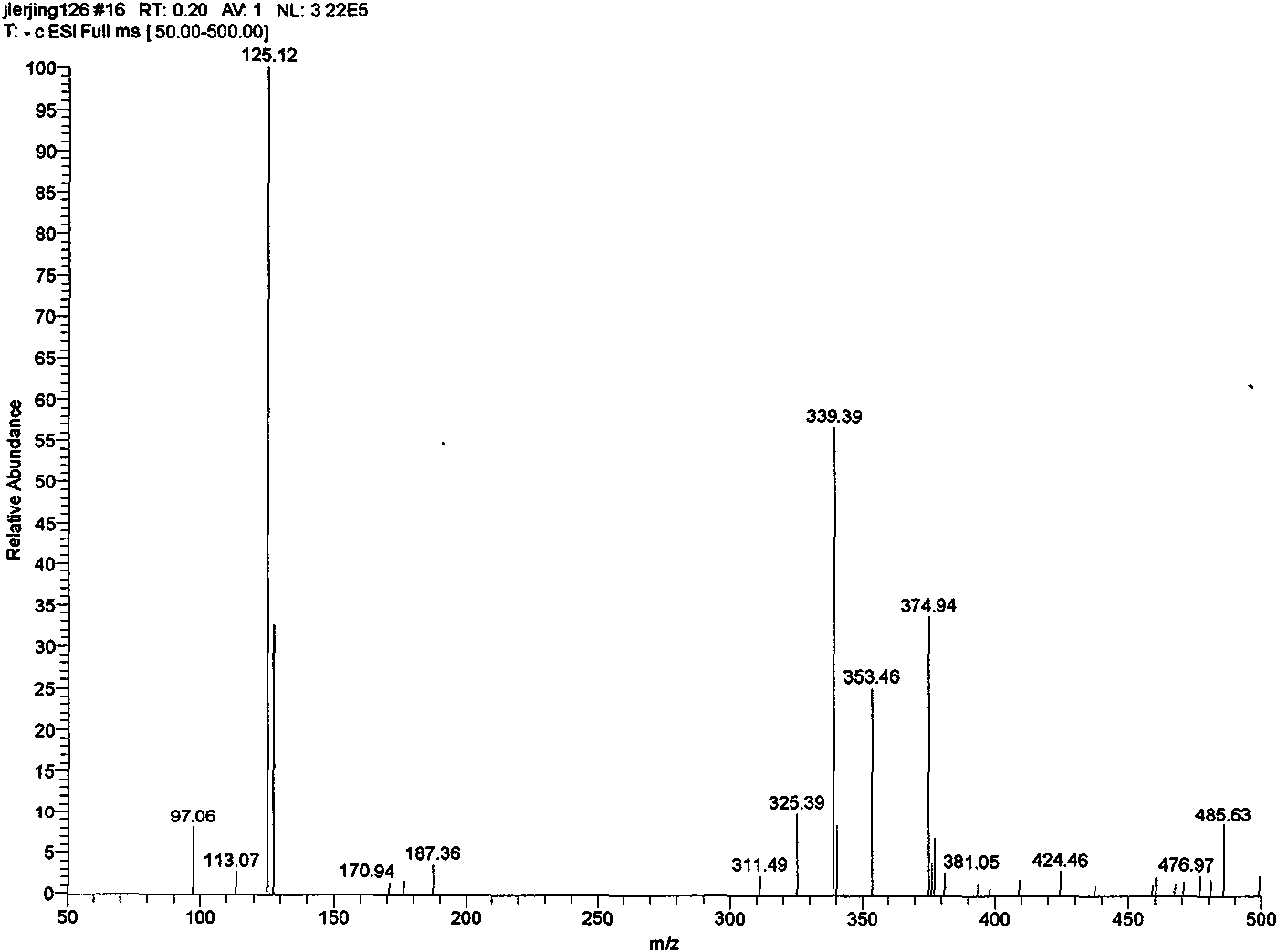

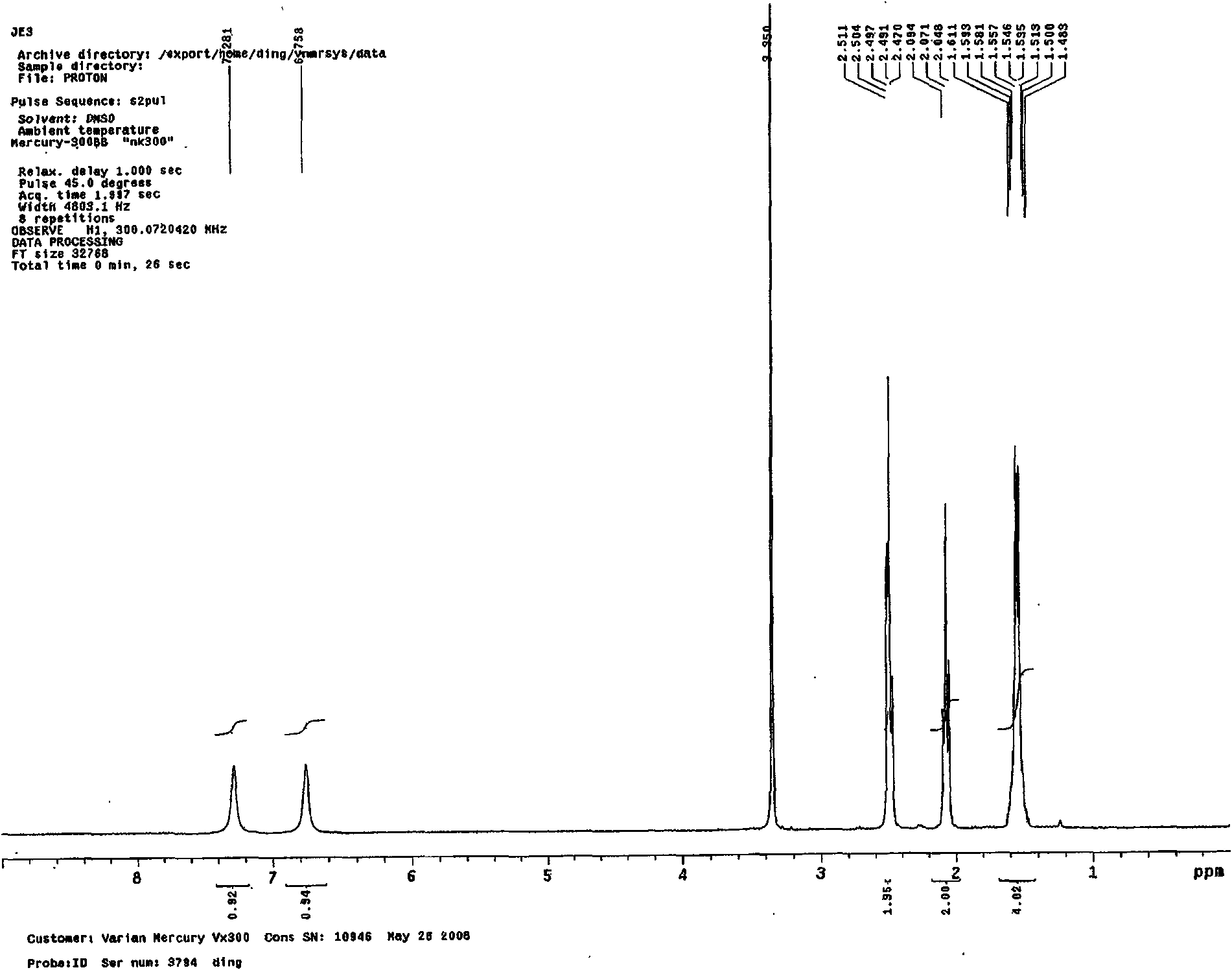

Image

Examples

Embodiment 1

[0031] A kind of method utilizing Rhodococcus rubrum to prepare 5-cyanopentanamide, the preparation steps are:

[0032] (1) Seed culture: add 30mL seed medium to a 250mL shake flask, pick a ring from the preserved slant strains and inoculate it into the seed medium, cultivate at 30°C and 180rpm for 28 hours to obtain a seed solution;

[0033] Seed medium: 1% glycerol, 0.5% peptone, 0.3% malt powder, 0.3% yeast powder, 0.1% NaCl, pH 7.2, sterilized at 121°C for 20 minutes.

[0034] (2) Fermentation culture: Add 30mL fermentation medium into a 250mL shake flask, insert the seed solution according to the inoculum size of 3%, and cultivate at 28°C and 180rpm for 48h;

[0035] Fermentation medium: 2% glucose, 0.5% yeast powder, 0.05% K 2 HPO 4 , 0.05% KH 2 PO 4 , 0.4% MgSO4 ·7H 2 O, 0.7% urea, 0.2% NaCl, 0.002% CoCl 2 , 0.1% sodium glutamate, pH 7.2, sterilized at 115°C for 20min; the inducer CoCl 2 and urea are sterilized separately, CoCl 2 Sterilize at 121°C for 20 minut...

Embodiment 2

[0045] Steps (1), (2), (3) and (5) in this embodiment are all the same as in Embodiment 1, and only step (4) is described below.

[0046] (4) Preparation of the crude product of 5-cyanovaleramide: the substrate adiponitrile concentration is 0.5mol / L, the reaction volume is 30mL, the cell concentration of Rhodococcus erythrococcus is 0.53g / L, 2.5% methanol is added, and the transformation system is 20mmol / L pH7.5 Tris-HCl buffer solution, the temperature is 30°C, the whole reaction is carried out in a water bath reactor, the rotation speed is 180rpm, and the conversion time is 120min. After the transformation, the transformation solution was centrifuged to remove the bacterial cells, and 20% ethanol was added to remove the water by rotary evaporation to obtain the crude product of 5-cyanovaleramide;

[0047] It is detected that the conversion rate of adiponitrile in this step reaches 100%, and the selectivity to 5-cyanovaleramide is 100%.

Embodiment 3

[0049] Steps (1), (2), (3) and (5) in this embodiment are all the same as in Embodiment 1, and only step (4) is described below.

[0050] (4) Preparation of the crude product of 5-cyanovaleramide: the substrate adiponitrile concentration is 0.8mol / L, the reaction volume is 30mL, the cell concentration of Rhodococcus erythrococcus is 0.53g / L, 2.5% methanol is added, and the transformation system is 20mmol / L pH7.5 Tris-HCl buffer solution, the temperature is 30°C, the whole reaction is carried out in a water bath reactor, the rotation speed is 180rpm, and the conversion time is 240min. After the transformation, the transformation solution was centrifuged to remove the bacterial cells, and 20% ethanol was added to remove the water by rotary evaporation to obtain the crude product of 5-cyanovaleramide;

[0051] It is detected that the conversion rate of adiponitrile in this step reaches 100%, and the selectivity to 5-cyanovaleramide is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com