Black phosphorus and phosphinidene preparing methods

A technology of black phosphorus and red phosphorus, applied in the preparation of phosphorus and other directions, can solve the problems of extremely high requirements for experimental instruments and equipment, and achieve the effects of cheap raw materials, simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

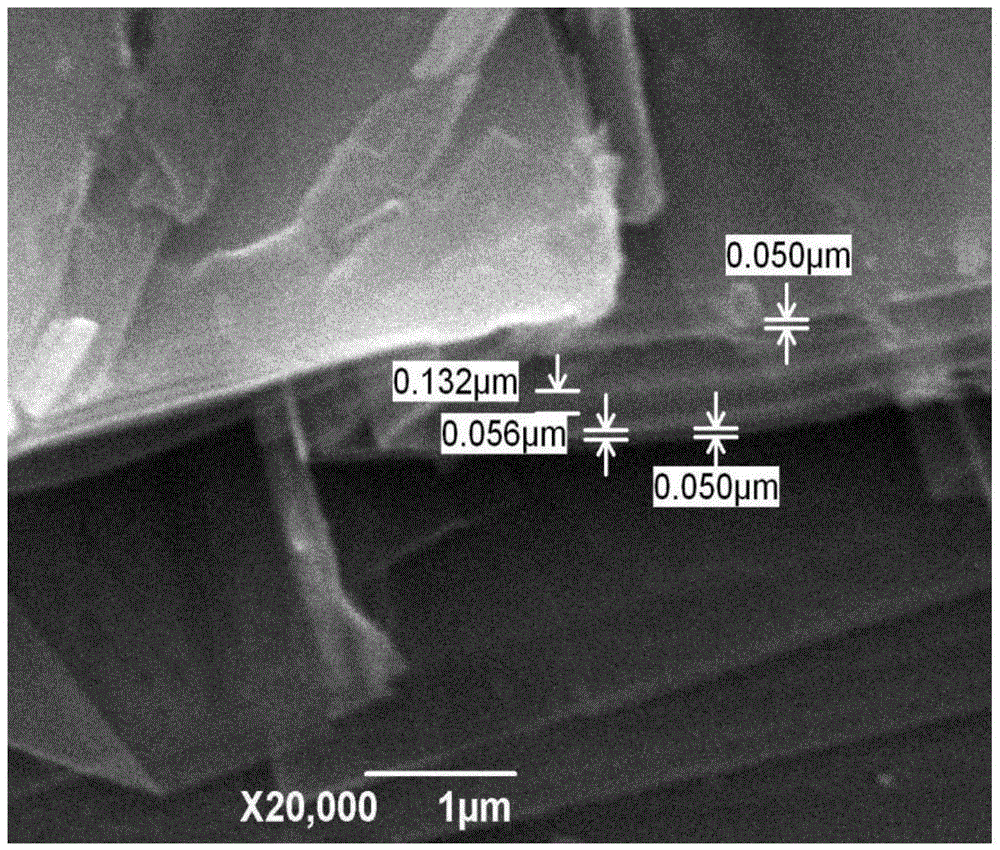

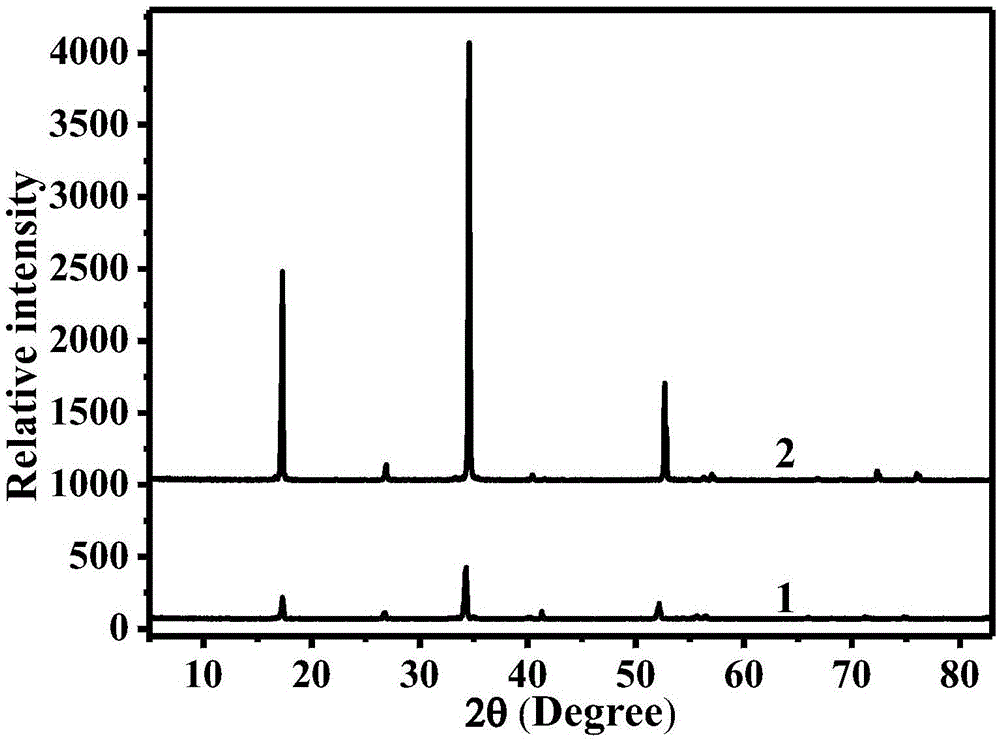

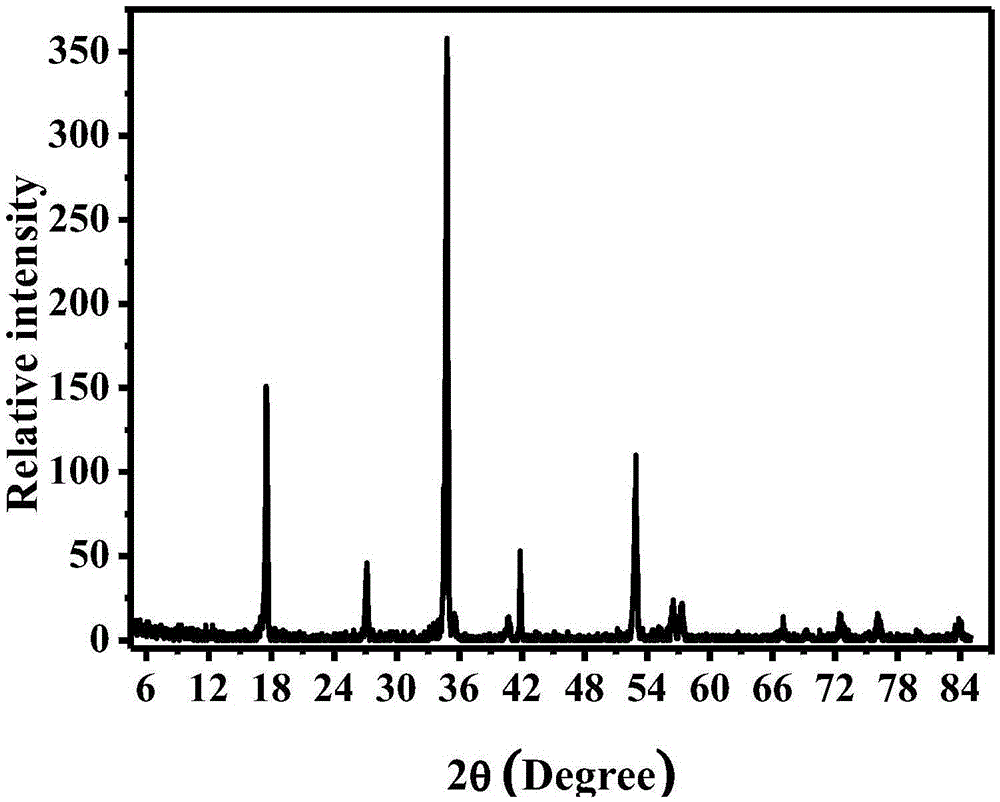

[0027] Add 0.5g red phosphorus, 0.02g tin, 0.01g tin tetraiodide into the glass quartz tube, then vacuum the quartz tube, when the vacuum degree reaches 10 -3 Fill a certain amount of argon at mbar, and encapsulate a quartz tube (inner diameter 0.8cm, length 8cm). Then set the following heating program in the muffle furnace:

[0028] Room temperature-320min-650℃-60min-650℃-450min-500℃-100min-500℃-330min-room temperature.

Embodiment 2

[0030] Add the target product obtained in Example 1 to 100ml of C 7 H 8 In the solvent, a water bath heating method is used for purification at a temperature of 90°C for 2 hours. After the purification is completed, it is dried in a vacuum drying oven at 80°C to obtain high-purity black phosphorus.

Embodiment 3

[0032] Add 0.5g red phosphorus, 0.02g tin, 0.01g tin tetraiodide into the glass quartz tube, then vacuum the quartz tube, when the vacuum degree reaches 10 -7 Fill a certain amount of argon at mbar, and encapsulate a quartz tube (inner diameter 0.8cm, length 8cm). Then set the following heating program in the muffle furnace: room temperature-320min-650℃-60min-650℃-450min-500℃-100min-500℃-330min-room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com