Monoalkyl/dialkyl phosphinate and preparation method thereof

A technology of alkyl phosphinate and mono-alkyl, applied in the field of mono-alkyl/di-alkyl phosphinate and its preparation, can solve the problem that it is difficult to obtain mono-alkyl phosphinate or hypophosphorous acid , to achieve the effect of high yield, low salt content and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

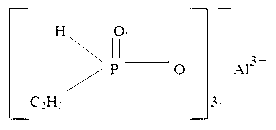

[0046] Embodiment 1: Structure and preparation of aluminum ethyl phosphinate

[0047] Add 444.1g (2mol) of aluminum hypophosphite, 500mL of water, 500mL of ethanol and 10.0g, 0.044mol of ammonium persulfate into the high-pressure reactor, seal it, and replace it with nitrogen (0.5MPa) for 5 times while stirring, and then pass ethylene through the regulator Adjust the pressure regulator to 2.5MPa and fill it in, heat it to 72°C, uniformly heat up to 75°C within 4h and use a metering pump to inject 5.0g, 0.022mol ammonium persulfate and 30mL water into the solution, and then at 75°C Insulate for 1 hour, cool and vent to obtain a mixed system of 1559.6g, which is equivalent to 175.5g of ethylene absorption (104.5% of the theoretical amount);

[0048] The resulting mixed system was filtered, washed twice with 1000 mL of water, and the obtained filter cake was vacuum-dried at 130° C. for 5 hours to obtain aluminum ethyl phosphinate: 583.7 g, with a yield of 95.37%, wherein the stru...

Embodiment 2

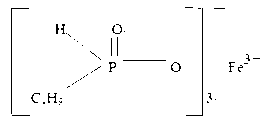

[0053] Example 2: Structure and preparation of aluminum diethylphosphinate

[0054] Add 444g (2mol) of aluminum hypophosphite, 300mL of water, 700mL of ethanol and 10.0g, 0.044mol of ammonium persulfate into the high-pressure reactor, seal it, replace it with nitrogen (0.5MPa) for 5 times while stirring, and then pass ethylene through the pressure regulator Adjust to 2.5MPa and fill it in, heat to 72°C, uniformly heat up to 75°C within 4 hours and use a metering pump to continuously inject 5.0g, 0.022mol of ammonium persulfate and 30mL of water into the solution; after 4.5 hours, Heat up to 95°C, uniformly heat up to 110°C within 4 hours, and use a metering pump to continuously inject a solution prepared by 15.0g ammonium persulfate and 90mL water, then keep warm at 110°C for 1 hour, cool and vent to obtain a mixed system 1794.1g, equivalent to 347.1g of ethylene absorption (103.3% of theoretical amount);

[0055] The resulting mixed system was filtered, washed twice with 100...

Embodiment 3

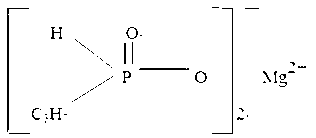

[0061] Example 3: Structure and preparation of aluminum diethylphosphinate

[0062] Add 444.0g (2.00mol) of aluminum hypophosphite, 500mL of water and 500mL of methanol into the high-pressure reactor, seal it, and replace it with nitrogen (0.5MPa) for 5 times while stirring, then adjust the ethylene to 2.5MPa through a pressure regulator and fill it with 20.0 g, 0.088 mol of ammonium persulfate and 120 mL of water are evenly poured into the solution within 9 hours with a metering pump, and the temperature is evenly raised to 110 ° C, and then kept at 110 ° C for 1 hour, cooled Vented to obtain 1832.1g of the mixed system, which is equivalent to 353.1g of ethylene absorption (105.1% of the theoretical amount);

[0063] The resulting mixed system was filtered, washed twice with 1000 mL of water, and the obtained filter cake was vacuum-dried at 130°C for 5 hours to obtain aluminum diethylphosphinate: 751.0 g, yield 96.27%, wherein, aluminum diethylphosphinate The structural form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com