Flame resistant semiaromatic polyamide resin composition and articles therefrom

A technology of semi-aromatic polyamide and polyamide resin, applied in the field of non-halogenated flame-retardant thermoplastic semi-aromatic polyamide composition, which can solve the problems of poor surface appearance of molded products

Inactive Publication Date: 2010-08-04

EI DU PONT DE NEMOURS & CO

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Degradation products of halogenated flame retardants can also contribute to poor surface appearance of molded articles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to 5 and comparative Embodiment 1 to 3

[0052] The compositions of Examples 1 to 5 and Comparative Examples 1 to 3 were prepared by melt blending the components shown in Table 1 in a twin-screw extruder. After exiting the extruder, the blended composition was cooled and cut into pellets. The pellets were surface coated with 0.1% by weight calcium montanate.

[0053] Each sample was rated V-0 according to the UL-94 flammability test on 1 / 16" and 1 / 32" thick rod stock.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

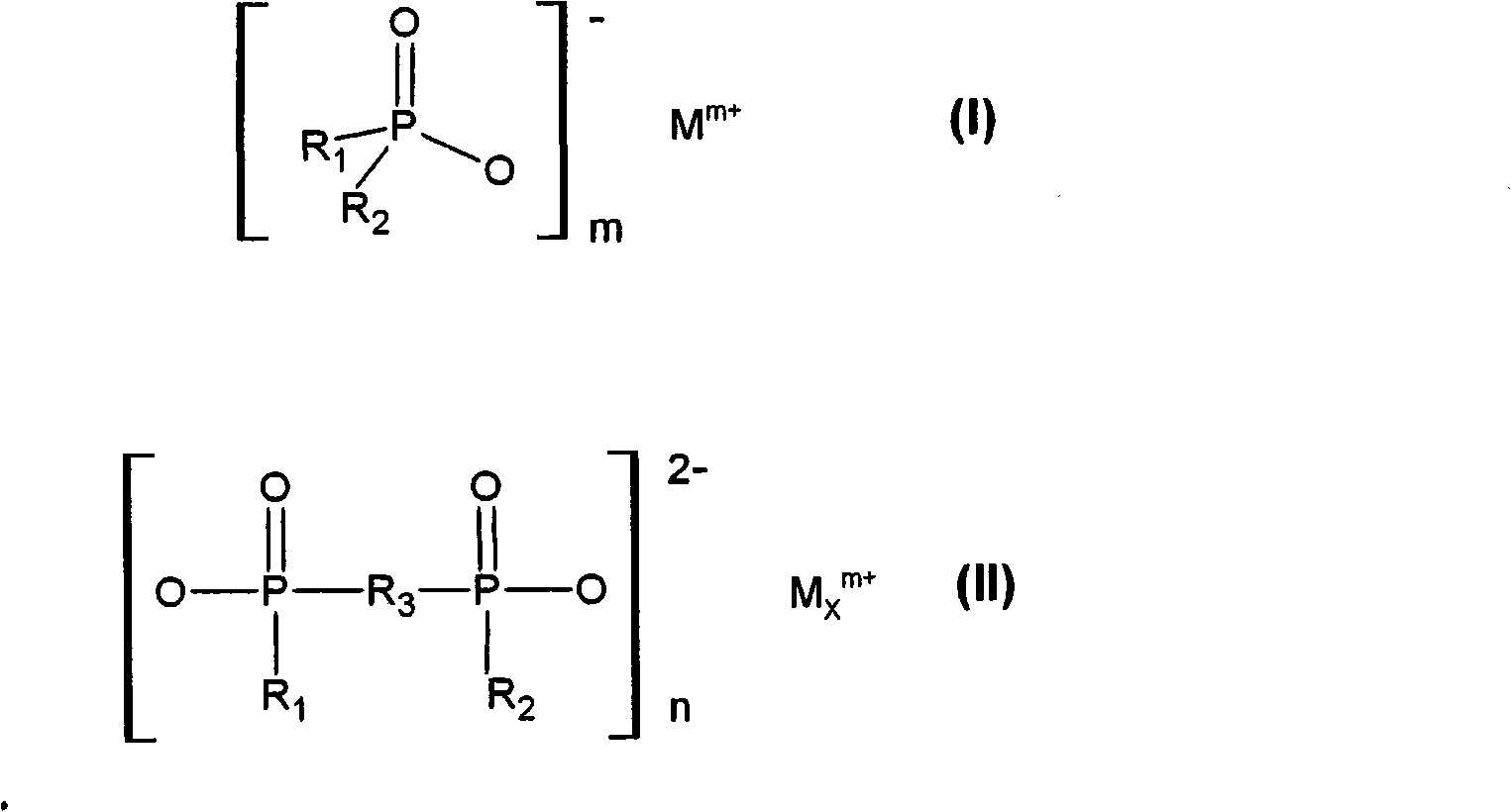

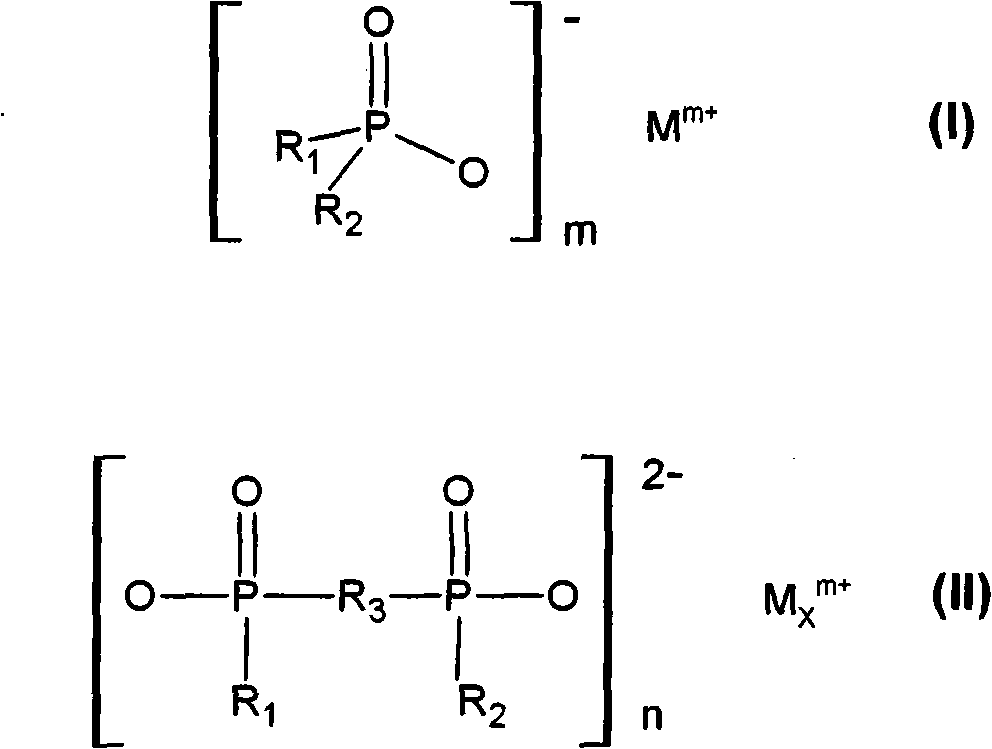

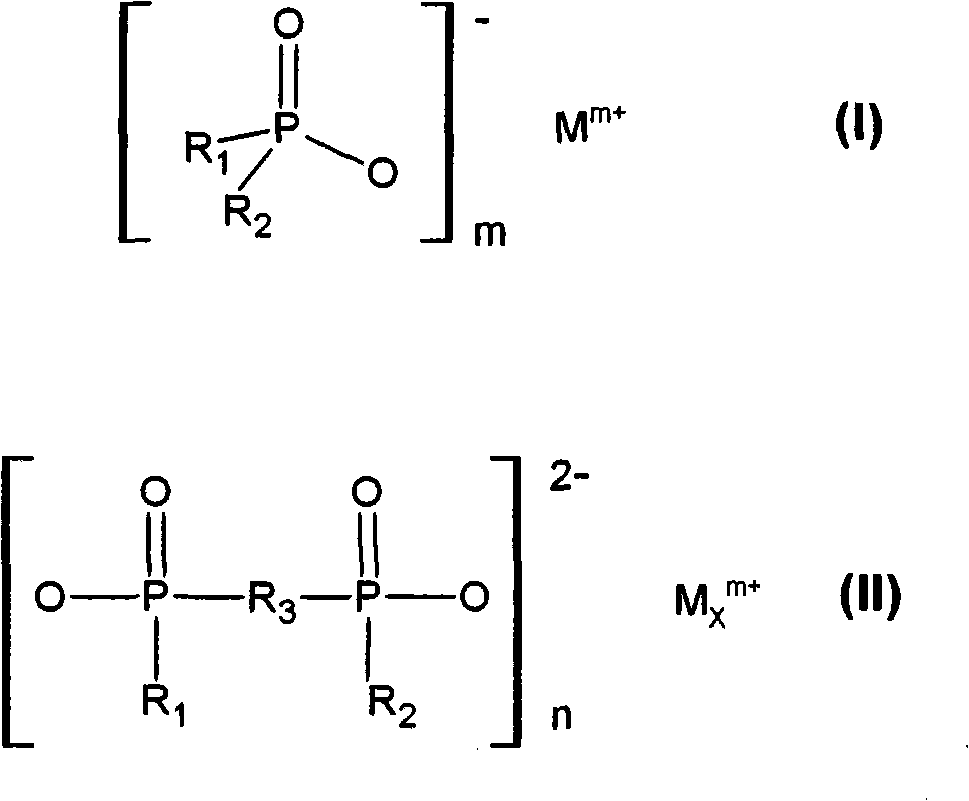

Disclosed are polyamide compositions containing a polyamide component comprising 20 to 100 weight percent of at least one semiaromatic polyamide, non-halogenated flame retardant comprising one or more of a phosphinate, a disphosphinate and polymers thereof, and zinc borate that have reduced corrosion effects on melt processing equipment.

Description

field of invention [0001] The present invention relates to non-halogenated flame retardant thermoplastic semiaromatic polyamide compositions that reduce the effects of corrosion on melt processing equipment. Background of the invention [0002] Polyamide resins have excellent mechanical properties, moldability, and chemical resistance, and thus have been used in automotive parts, electrical / electronic components, mechanical assemblies, and many other applications. Articles made from polyamide resins can have extremely desirable physical properties. However, in certain applications, it is desirable that the polyamide resin composition be flame retardant and comply with the UL-94 standard for high flame retardancy. This requirement has prompted the development of various methods for imparting flame retardancy to polyamide resins. A common method of imparting flame retardancy to thermoplastic resin compositions involves the incorporation of halogenated organic compounds such ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L77/06C08K5/5313C08K3/38

CPCC08K3/22C08K3/38C08K5/5313C08K7/14C08K2201/014

Inventor Y·殷

Owner EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com