Preparation method and application of dialkyl phosphinate with high density and large diameter

A technology of dialkyl phosphinate and alkyl phosphinate, which is applied in the field of preparation of high density and large particle size dialkyl phosphinate, can solve the problem of low particle size of dialkyl phosphinate, Plastic particles are difficult to mix evenly, which is not conducive to resin molding processing, etc., to achieve the effect of easy feeding, small dust and easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

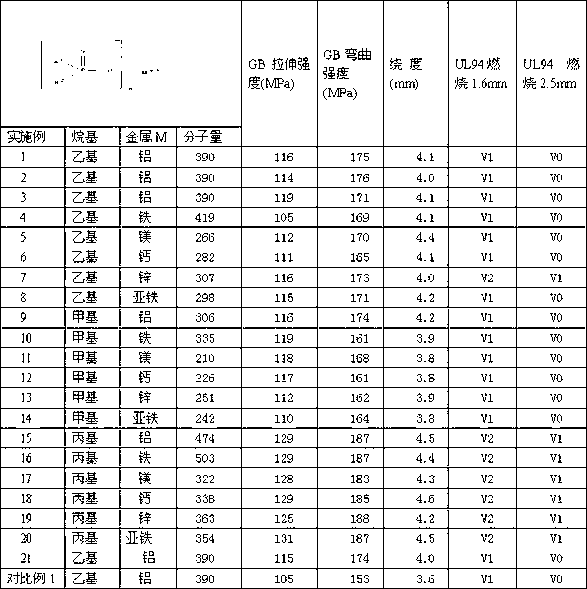

Examples

Embodiment 1

[0040] (1) Synthesis of dialkylphosphinic acid and / or alkali metal salt of dialkylphosphinic acid

[0041] The dialkylphosphinic acid and / or the alkali metal salt of dialkylphosphinic acid used in the examples listed in the method of the present invention are all synthesized with reference to Chinese patent CN 201010613835.6.

[0042] (2) Preparation of aluminum diethylphosphinate

[0043] Add 2711g and 10mol of 45% diethylphosphinic acid aqueous solution into the reactor, add 3000g and 30mol of 40% NaOH aqueous solution into the reactor, stir and heat to 95°C, add 40% octadecadecanoic sulfuric acid Add 2780g and 1.67mol of aluminum aqueous solution within 60min, neutralize with 30% sulfuric acid aqueous solution to obtain solid precipitation, cool, filter, wash with water, and dry; obtain 1253g of aluminum diethylphosphinate, yield 96.4%; bulk tap density It is 610g / L; the product particle size (μm) distribution is: D(10): 34; D(50): 71; D(90): 128;

[0044] IR: 779CM -1 ,...

Embodiment 2

[0046] Same as in Example 1, potassium hydroxide was used as the basic compound, 4200 g and 30 mol of a 40% KOH aqueous solution were added to the reactor to obtain 1246 g of aluminum diethylphosphinate, with a yield of 95.8%; the bulk tap density was 640 g / L; Product particle size (μm) distribution: D(10): 39; D(50): 77; D(90): 122.

Embodiment 3

[0048]Same as in Example 1, aluminum chloride is used for the metal compound, hydrochloric acid is used for the acid solution, 2010 g of an aqueous solution with a mass fraction of 40% aluminum chloride hexahydrate is made, and 3.33 mol is added within 60 minutes, and neutralized with 17% hydrochloric acid to obtain diethyl Aluminum phosphinate 1248g, yield 96.0%; bulk tap density 600g / L; product particle size (μm) distribution: D(10): 38; D(50): 77; D(90): 121.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com