Monoalkyl/dialkyl phosphinate and preparation method thereof

A technology of alkyl phosphinate and mono-alkyl is applied in the field of mono-/di-alkyl phosphinate and its preparation, and can solve the problem that it is difficult to obtain mono-alkyl phosphinate or hypophosphorous acid and the like , to achieve the effect of high yield, easy washing and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

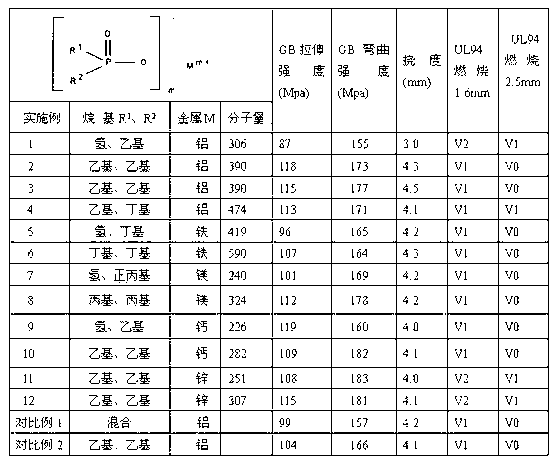

Examples

Embodiment 1

[0051] Embodiment 1: Structure and preparation of aluminum ethyl phosphinate

[0052] Add 444.0g (2mol) of aluminum hypophosphite, 1500mL of water and 10.0g (0.044mol) of ammonium persulfate into the high-pressure reactor, seal it, and replace it with nitrogen (0.5MPa) for 5 times while stirring, and then pass ethylene through the pressure regulator Adjust to 2.5MPa and fill in, heat to 72°C, uniformly heat up to 75°C within 4h and use a metering pump to pour in a solution made of 5.0g (0.022mol) ammonium persulfate and 25mL of water, and then keep warm at 75°C After 1 hour, cool and vent, and obtain 2156.2 g of the aluminum ethylphosphinate-water mixed system, which is equivalent to 172.2 g of ethylene absorption (equivalent to 102.5% of the theoretical amount);

[0053]The obtained aluminum ethylphosphinate-water mixed system was heated to 95°C and filtered, washed once with 1000 mL of hot water at 95°C, and the solid was vacuum-dried at 130°C for 5 hours to obtain aluminum...

Embodiment 2

[0058] Example 2: Structure and preparation of aluminum diethylphosphinate

[0059] Add 444g (2mol) of aluminum hypophosphite, 1500mL of water and 10.0g (0.044mol) of ammonium persulfate into the high-pressure reactor, seal it, replace it with nitrogen (0.5MPa) for 5 times while stirring, and then adjust the ethylene through a pressure regulator Charge to 2.5MPa, heat to 72°C, uniformly heat up to 75°C within 4 hours and continuously inject a solution of 5.0g (0.022mol) ammonium persulfate and 25mL water with a metering pump; after 4.5 hours, heat Raise the temperature to 95°C, uniformly raise the temperature to 110°C within 4 hours, and use a metering pump to continuously inject a solution prepared by 15.0g ammonium persulfate and 75mL water, then keep it at 110°C for 1 hour, cool and vent to obtain the diethyl The aluminum-based phosphinate-water mixed system is 2416g, which is equivalent to 342.0g ethylene absorption (101.8% of the theoretical amount).

[0060] The resul...

Embodiment 3

[0066] Example 3: Structure and preparation of aluminum diethylphosphinate

[0067] Add 444.0g (2.00mol) of aluminum hypophosphite and 1500mL of water into the high-pressure reactor, seal it, and replace it with nitrogen (0.5MPa) for 5 times while stirring, then adjust ethylene to 2.5MPa through a pressure regulator and fill it in, heat to 95°C, within 11 hours, use a metering pump to evenly inject a solution prepared by 20.0g (0.088mol ammonium persulfate) and 100mL water, and evenly raise the temperature to 110°C, then keep it at 110°C for 1 hour, cool and vent. The obtained aluminum diethylphosphinate-water mixed system is 2417.2g, which is equivalent to 343.2g of ethylene absorption (102.1% of the theoretical amount);

[0068] The resulting aluminum diethylphosphinate-water mixed system was filtered, washed once with 1000 mL of water, and the solid was vacuum-dried at 130°C for 5 hours to obtain aluminum diethylphosphinate: 756.1 g, with a yield of 96.93%. The structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com