Flame-retardant polyester composition

A composition and polymer technology, applied in the field of flame retardant polyester composition, can solve the problems of lack of good flame retardancy of thin sheets and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

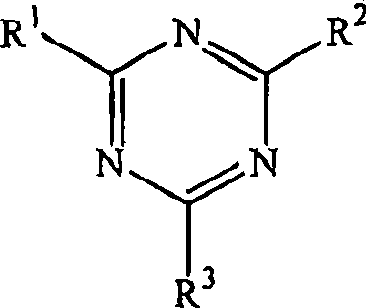

[0007] According to one embodiment, a composition comprises a polyester such as polybutylene terephthalate; a nitrogen-containing flame retardants; phosphinates of formula I and / or diphosphonates of formula II and / or polymers thereof as described below; and charred polymers.

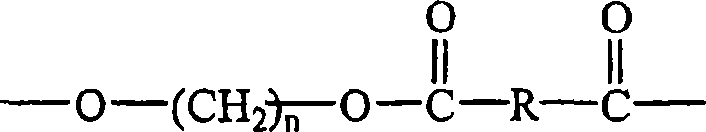

[0008] Preferred polyesters are obtained by copolymerization of a diol component and an acid component comprising at least about 70 mole percent, preferably at least about 80 mole percent, of terephthalic acid or a polyester-forming derivative thereof. The preferred diol (butanediol) component may contain up to about 30 mol%, preferably up to about 20 mol%, of another glycol such as ethylene glycol, propylene glycol, 2-methyl-1,3-propanediol, hexamethylene glycol Alcohols, decanediol, cyclohexanedimethanol, neopentyl glycol, etc., and mixtures comprising at least one of the above diols. A preferred acid component may contain up to about 30 mol%, preferably up to about 20 mol%, of another acid such as is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com