Sheet producer for masks

A mask and body technology, applied in the field of mask processing equipment, can solve the problems of poor aesthetics, low production efficiency, and many production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

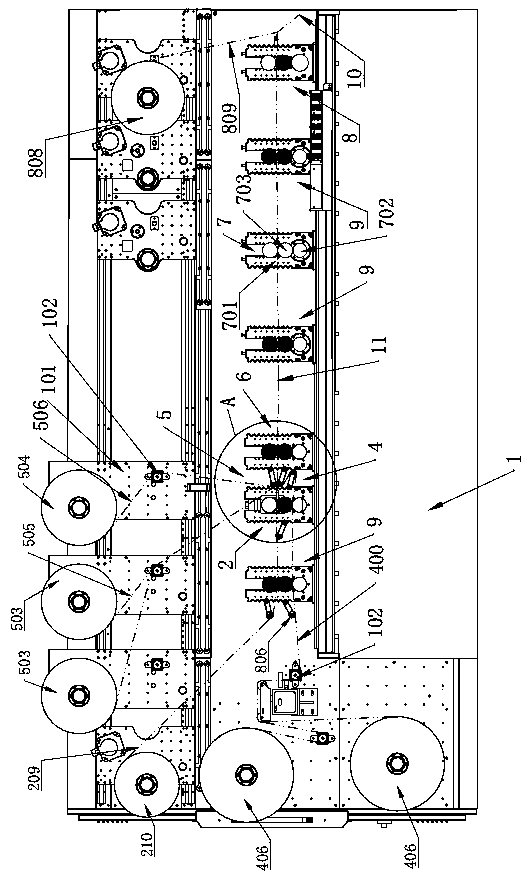

[0050]Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and cannot be used to limit the protection scope of the present invention.

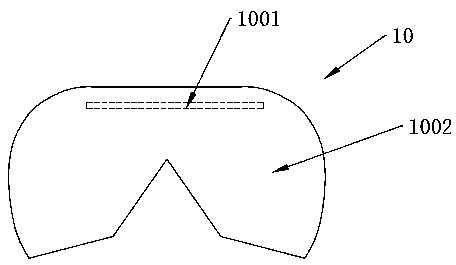

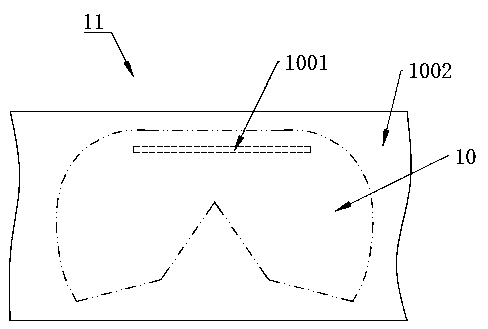

[0051] For ease of description, the double dotted lines shown in the figure are various materials (nose bridge line 209, first cloth layer 400, second non-woven fabric 506, melt-blown cloth 505, composite body 11, waste material 809 and mask body 10 ) delivery route.

[0052] Such as Figure 3 to Figure 6 Commonly shown, a mask punching machine includes a body 1, the body 1 is provided with a nose bridge line material cutting mechanism 2, and the downstream of the nose bridge line material cutting mechanism 2 is provided with a nose bridge strip guide mechanism 3; The body 1 is also provided with a first clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com