Grinding disc and high-speed rail bridge grinder provided with same

A grinding machine and grinding disc technology, which is applied to machine tools, grinding/polishing equipment, grinding machines, etc., which are suitable for grinding workpiece planes, and can solve problems such as the easy breakage of the positioning pin of the grinding block, the influence of the lower knife, and the easy upward jump of the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

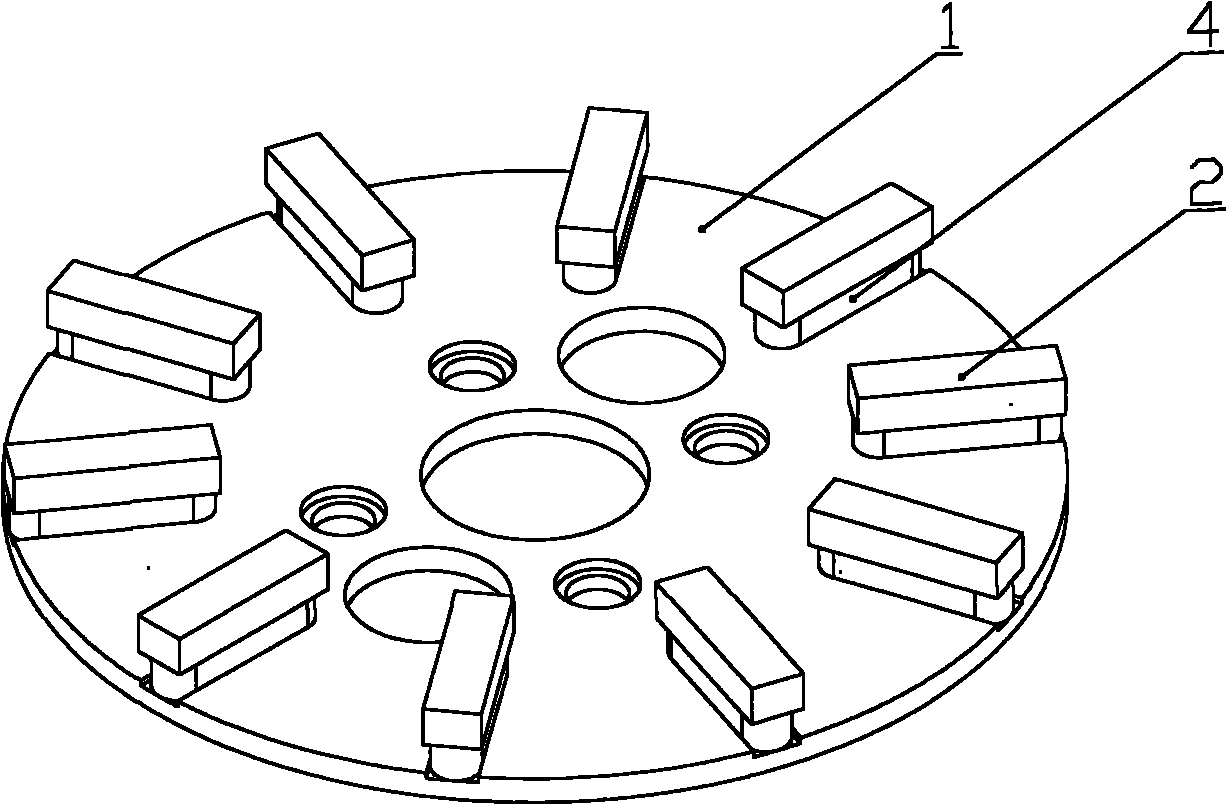

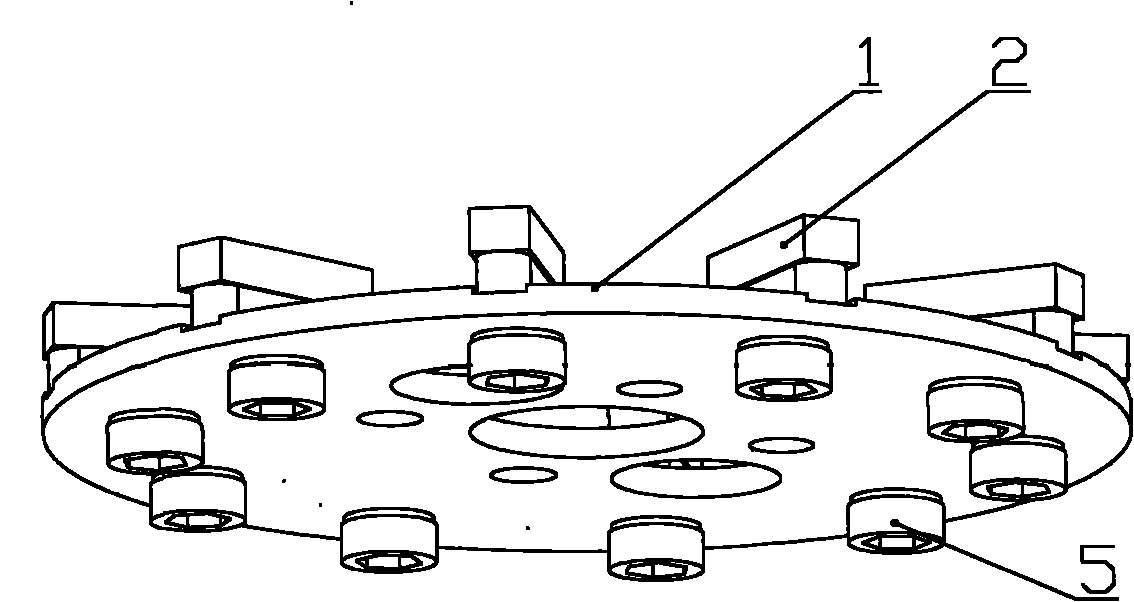

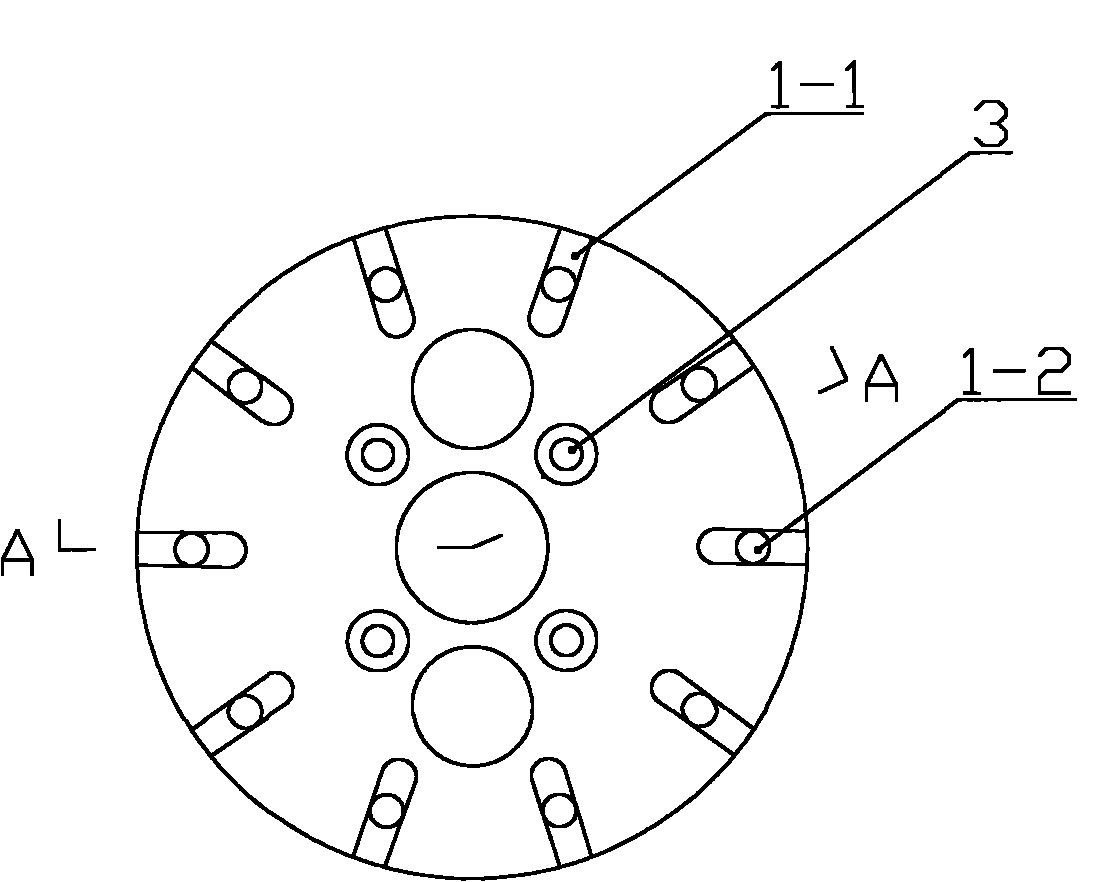

[0039] The core of the invention is to provide a grinding disc. The grinding disc adopts a split design, no welding is required between the grinding block and the disc body, the installation is simple, and the operation is convenient. When the grinding block is completely worn out, only the grinding block needs to be replaced instead of the disc body, which saves costs; The wear of the disc body prevents the sliding of the grinding block to the greatest extent and ensures the effective working performance of the grinding block. Another core of the present invention is to provide a high-speed rail bridge grinding machine provided with the above-mentioned grinding disc.

[0040] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] The words "upper, lower, inner, outer" in this article ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com