Tool for grinding S-shaped bent pipe

A technology for bending pipes and tools, which is applied in the field of grinding S-shaped pipe bending tools, which can solve the problems that the smoothness of the inner wall cannot be guaranteed and the pipes are small, and achieve the effects of simple structure, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

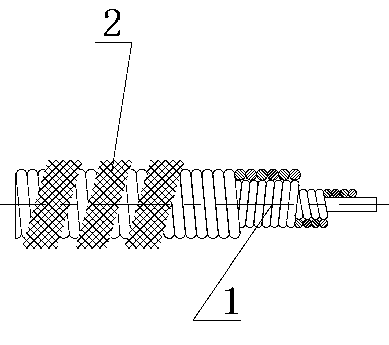

[0015] A kind of grinding S-shaped pipe bending tool of the present embodiment, such as figure 1 As shown, it includes a grinding head 2 and a flexible shaft 1, the grinding head 2 is covered on one end of the flexible shaft, and the other end of the flexible shaft 1 is connected to the driving device. The grinding head 2 is a non-woven abrasive flat belt with a nylon base layer, and the non-woven abrasive flat belt with a nylon base layer is glued and coated on the surface of one end of the flexible shaft 1; the flexible shaft 1 includes 4 layers of steel wire winding layers, each The steel wire winding layer is formed by winding 4 to 12 steel wires side by side, and the steel wires are either flat steel wires or round steel wires.

[0016] The grinding S-shaped pipe bending tool in this embodiment utilizes the characteristics of the flexible shaft 1, and the grinding head 2 is equipped with a nylon-based non-woven abrasive flat belt combined with the flexible shaft 1, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com