Piston pin grinding device for machining

A technology for mechanical processing and piston pins, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of low efficiency of piston pin grinding and processing, reduce equipment investment costs, save time and cost, and improve grinding efficiency and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

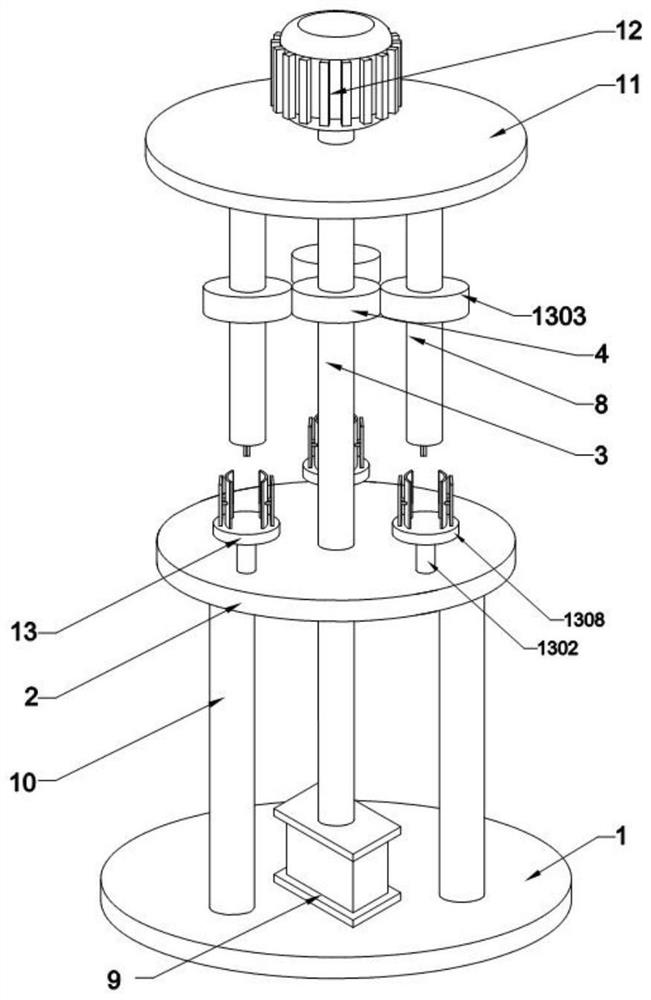

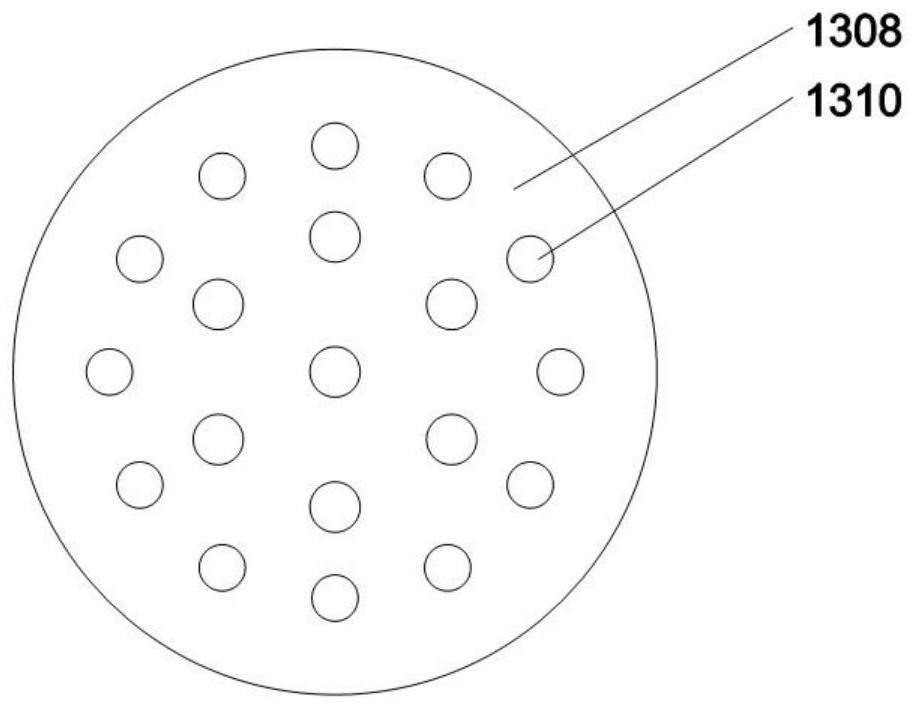

[0031] refer to Figure 1-3 , a piston pin grinding device for mechanical processing, comprising a base 1, an air compressor 9 is fixedly connected directly above the base 1, the exhaust pipe of the air compressor 9 communicates with the gas storage tank, and a second air compressor is arranged directly above the base 1 A support plate 2, the base 1 is fixedly connected to the first support plate 2 through a support rod 10, a second support plate 11 is arranged directly above the first support plate 2, and the first support plate 2 is connected to the second support plate 11 through a transmission rod 3 Connected, between the first support plate 2 and the second support plate 11, there are a number of grinding assemblies 13 distributed in a circular array centered on the central axis of the transmission rod 3; drive gears 4 are provided on the sides of the transmission rod 3; the second support The top bolt of the plate 11 is fixedly connected with the servo motor 12, the outp...

Embodiment Embodiment 1

[0041] When implementing Example 1, the inventor found that the driving gear 4 and the driven gear 1303 on the top of the first support plate 2 are easy to pinch the hair of the staff, causing personal injury to the staff, so the inventors based on Example 1 The following improvements have been made.

[0042] refer to Figure 5 , Figure 6 As shown, the outer side of the first support plate 2 is provided with a protective cover 8, the protective cover 8 is a cylindrical structure compatible with the first support plate 2, the top of the protective cover 8 is an open structure and the bottom is provided with a structure corresponding to the pole 10. Adaptive openings, the inside of the protective cover 8 is fixedly connected with three clips 5, and the outer wall of the first support plate 2 is provided with clip slots 6 that are compatible with the clips 5, and the three clip slots 6 are distributed in a circular array and the array The center is located on the central axis ...

Embodiment 3

[0045] Due to the existence of chamfers in the inner diameter of some existing piston pins, the chamfers of the piston pins cannot be ground according to the method of the above-mentioned embodiment 1, and it needs to be polished manually or using a special grinding equipment alone, which will occupy the workshop space. , and the equipment investment is large, so the inventor made the following further improvements on the basis of Embodiment 1.

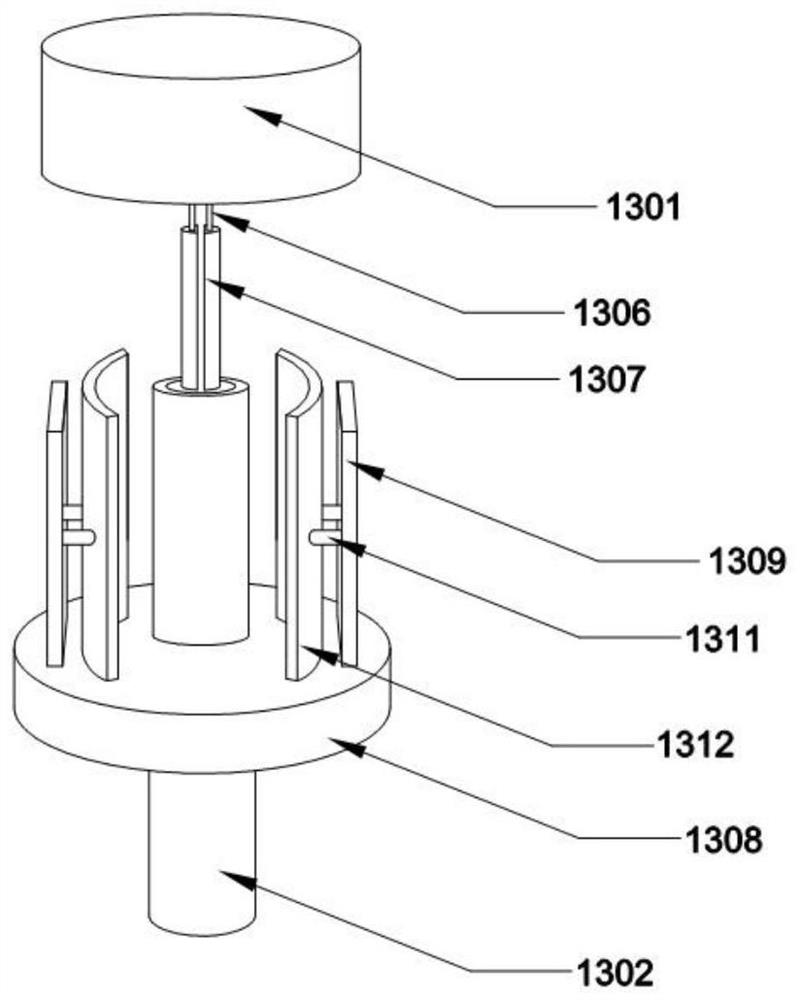

[0046] refer to Figure 7-9 As shown, the sliding assembly 1306 includes two vertical plates, and a "T"-shaped beam is arranged between the two vertical plates. It is fixedly connected with the first electromagnet 1307, and the side of the lower leg of the "T" beam is connected with the spacer 1305 through a spring.

[0047] One end of the spring on the left side of the spacer 1305 is connected to the side of the lower leg of the "T" beam, the other end of the spring on the left side of the spacer 1305 is connected to the second elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com