Accurate grinding method for tiny ball nuts

A technology of ball screw nut and precision grinding, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the difficulty of grinding and processing ball nut nut, and the surface roughness of ball nut nut can not reach the ball wire Bar pair and other problems to achieve the effect of increasing the range and realizing precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with embodiment:

[0012] 1. Transformation of lathe:

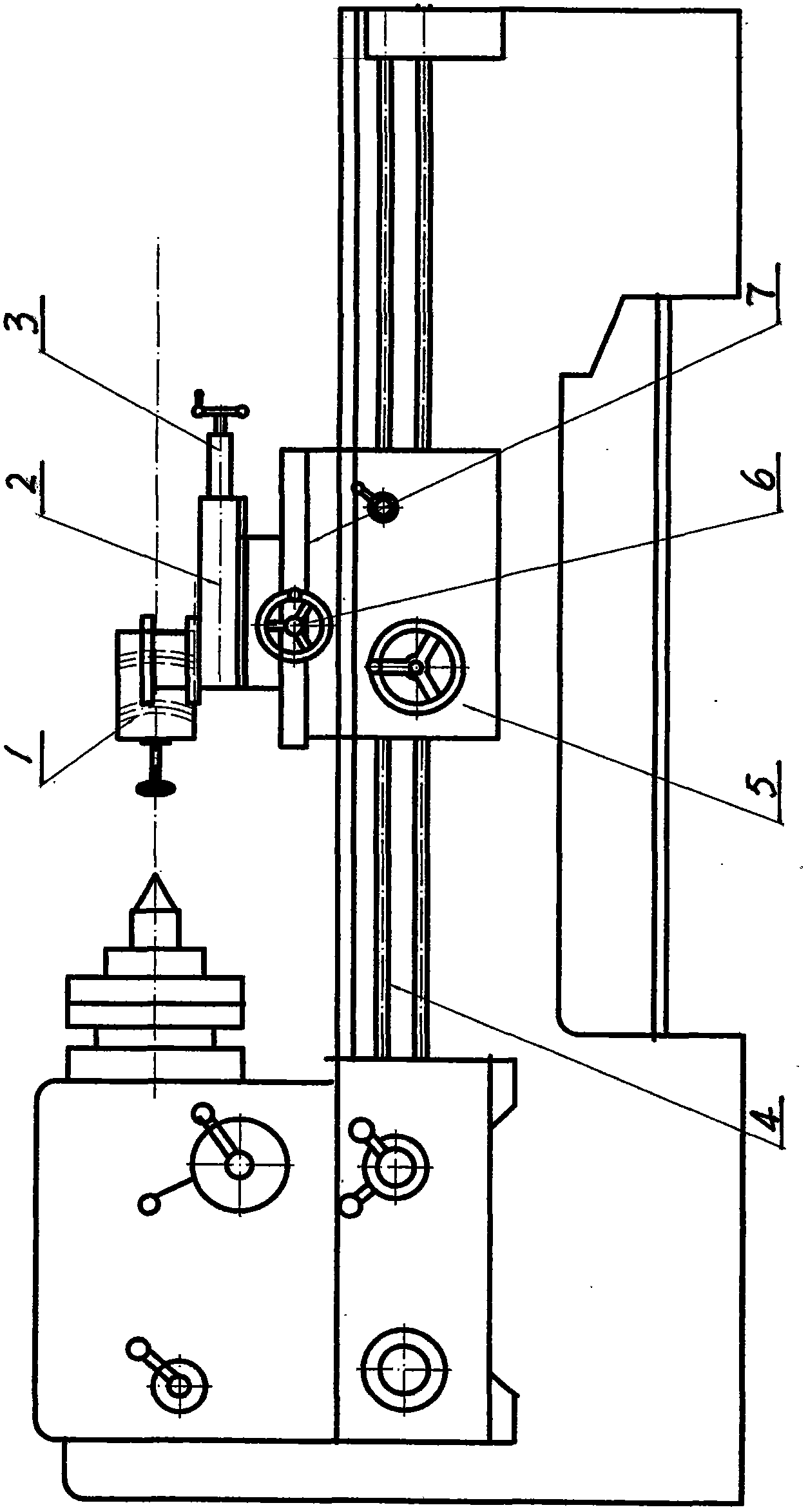

[0013] (1). Change the longitudinal screw 4, horizontal screw 6 and tool holder T-type screw 3 on the ordinary lathe into precision ball screws to improve the running accuracy and repeat positioning accuracy of the machine tool, and meet and meet the needs of ball screw nuts. Grinding accuracy requirements;

[0014] (2). Adjust the matching between the large supporting plate 5, the middle supporting plate 7 and the small supporting plate 2 on the ordinary lathe to ensure the stability during grinding;

[0015] 2. Install the electric spindle grinding head and the helix angle adjustment mechanism 1 on the tool holder, that is, install the electric spindle grinding head of 80,000 to 120,000 rpm to ensure that when grinding the small medium-diameter wire nut raceway, The grinding wheel has sufficient cutting speed (10 m / s ~ 15 m / s). However, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com