Special abrasive particle landform for steel grinding abrasive disk and diamond abrasive disk and preparation method of special abrasive particle landform

A diamond and abrasive particle technology, applied in the field of surface topography and preparation of diamond abrasive discs, can solve the problems of point-shaped area adhesion, large sparks in the grinding process, and exposure of abrasive particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0082] Develop a brazed diamond grinding disc for grinding and polishing marine steel surface. Grinding disc size 125mm, inner hole 22.23mm

[0083]Due to the high strength and toughness of marine steel, diamond tools are prone to surface adhesion during processing. On the other hand, due to surface grinding and polishing, it is necessary to achieve a certain surface quality and not be too rough. Therefore, the design uses diamonds with a particle size of 45 mesh. HSD80 grade.

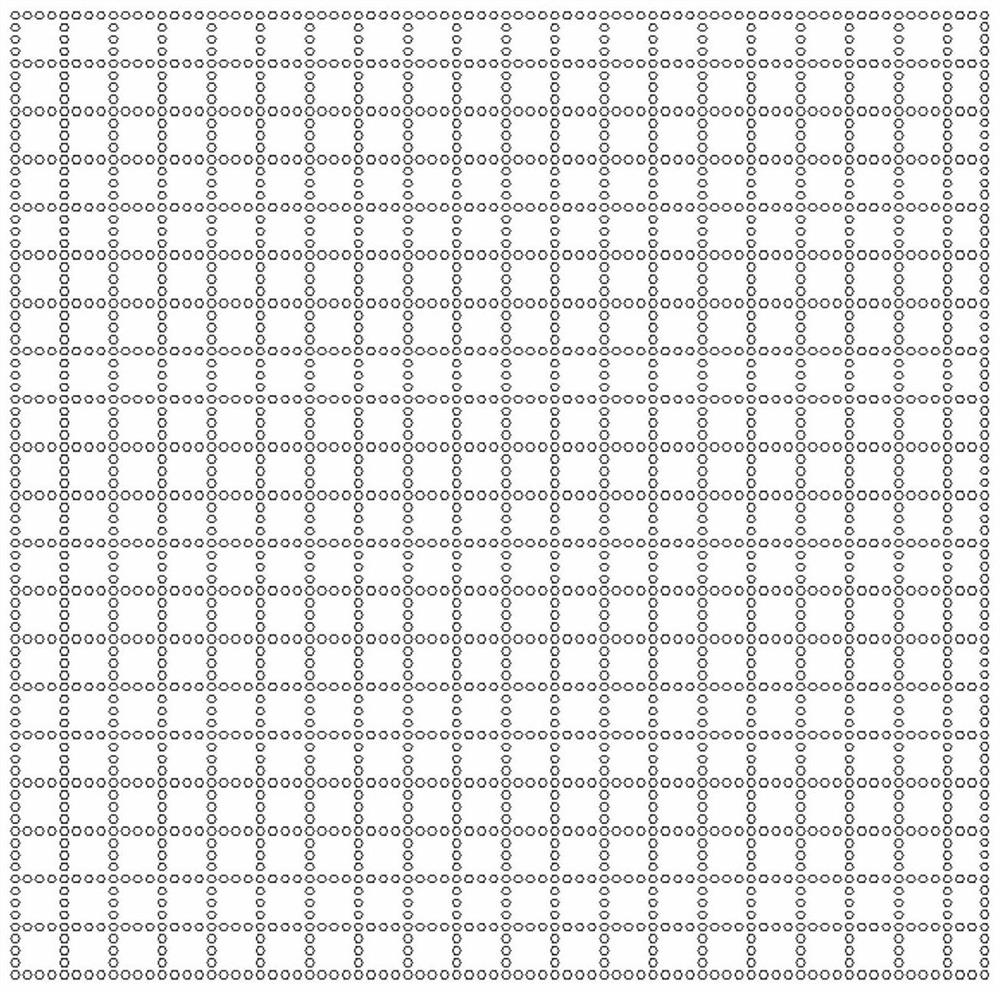

[0084] Due to the stable surface in the grinding and polishing process, a simple circular hole structure is used as the heat dissipation hole. The diameter of the circular hole is 3.5mm, and the abrasive grain width is 1.2mm.

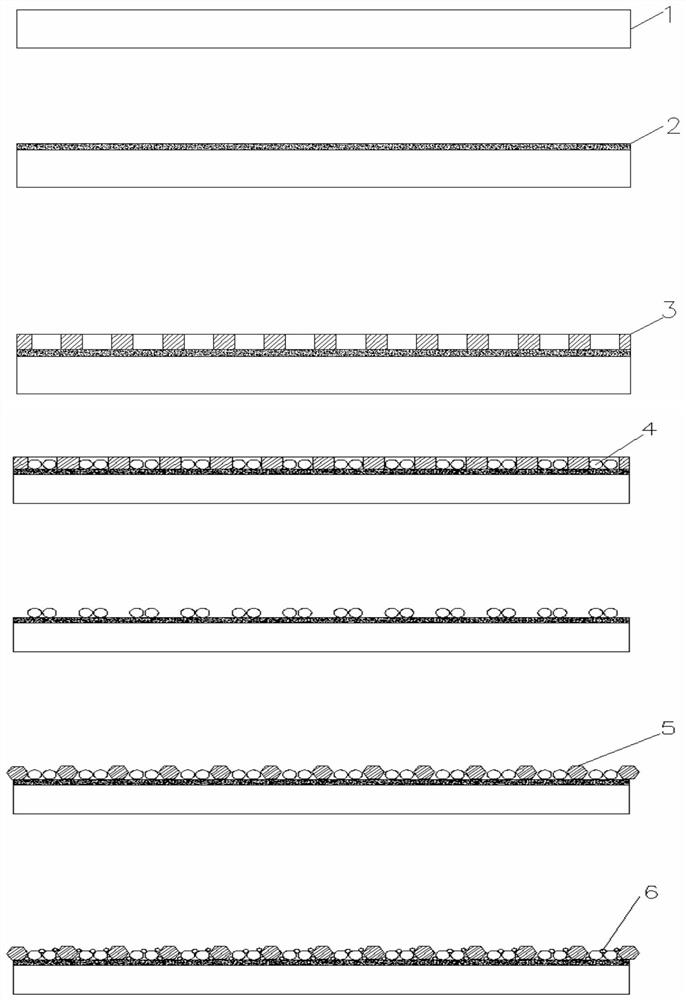

[0085] The preparation steps are as follows:

[0086] (1) Use 0.2mm thick silica gel film and laser cut to prepare mesh partitions.

[0087] (2) Brush the adhesive on the area to be clothed on the surface of the grinding disc.

[0088] (3) Paste the mesh partition so that th...

specific Embodiment 2

[0094] A brazed diamond grinding disc for surface grinding of cast steel was developed. Disc size 180mm, inner hole 22.23mm

[0095] Due to the high hardness of cast steel, the amount of grinding and removal on the surface is relatively large, and the diamond tool requires low vibration and high efficiency during processing. On the other hand, there should be no obvious burn area on the surface after surface grinding and polishing, so the design uses diamond with a particle size of 35 mesh. Zhongnan ZND2290 grade.

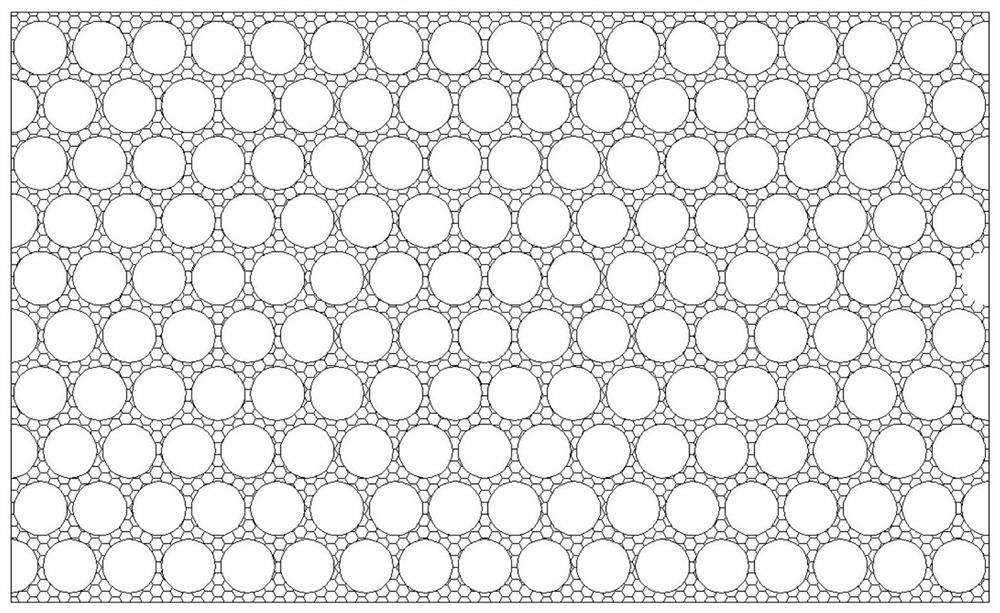

[0096] Due to the complex grinding and polishing surface, a hexagonal structure is used as the heat dissipation hole. The length of the longest side of the hexagon is 3mm, and the abrasive grain width is 1.5mm.

[0097] The preparation steps are as follows:

[0098] (1) Use 0.2mm thick silica gel film and laser cut to prepare mesh partitions.

[0099] (2) Brush the adhesive on the area to be clothed on the surface of the grinding disc.

[0100] (3) Paste the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com