Semicoke grinding system and method

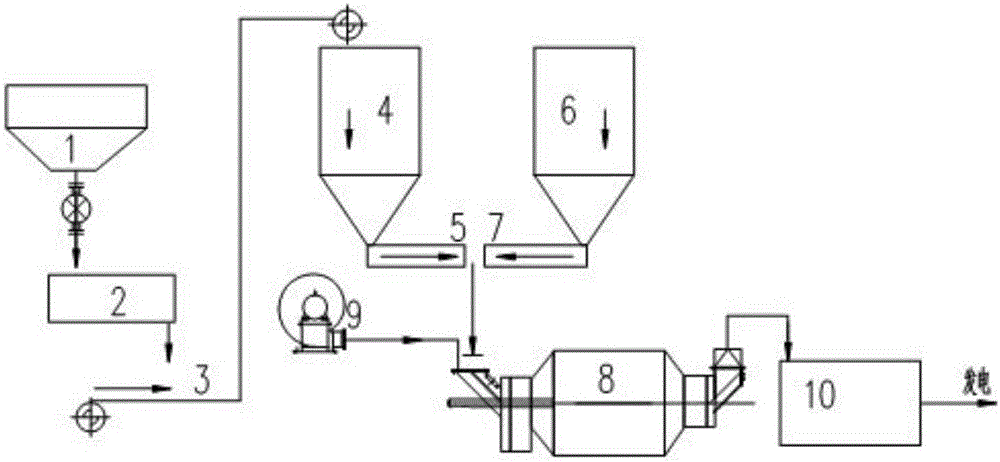

A technology of semi-coke and high-temperature semi-coke, which is applied in combustion methods, lighting and heating equipment, block/powder fuel preparation, etc. It can solve the problems of increasing production cost of semi-coke, consuming large cooling water, and limiting material temperature, etc. Achieve the effect of reducing energy waste, simplifying production process and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

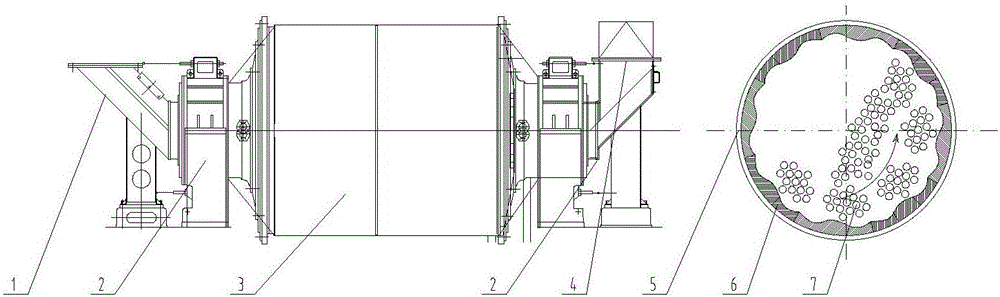

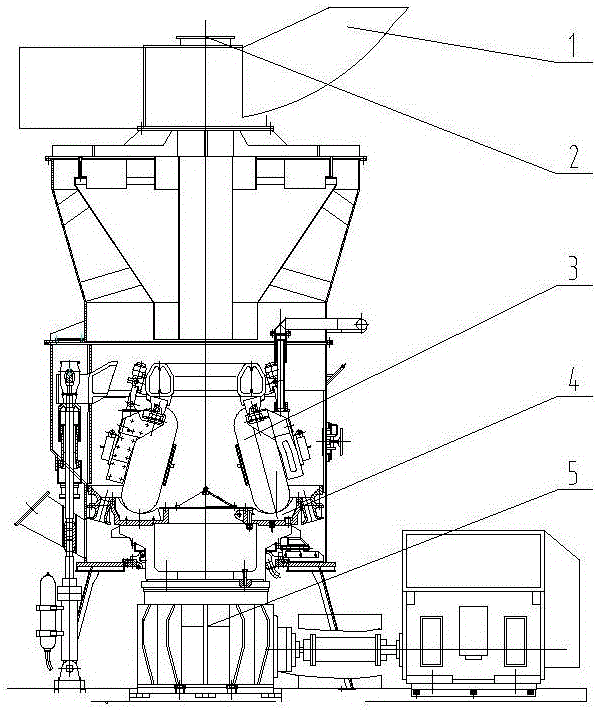

[0084] This embodiment proposes a semi-coke grinding system and grinding method. After the lignite is dried, it enters the pyrolysis furnace to generate semi-coke. The semi-coke and steam coal enter the coal mill according to a certain ratio to be ground and dried, and are ground into coal powder. After entering the pulverized coal boiler combustion produces steam to steam turbine power generation. The technical data of lignite are shown in Table 1:

[0085] Table 1: Technical data of lignite:

[0086]

[0087] The amount of lignite coal is designed to be 120t / h, and it enters the dryer through the feeder. After drying, the moisture Mt of the lignite is ≤ 10%, and then enters the pyrolysis furnace for pyrolysis.

[0088] Semi-coke is produced after lignite pyrolysis, the output is 65t / h, the semi-coke outlet temperature is 750°C, and the semi-coke parameters are as follows:

[0089] Table 2: High temperature semi-coke parameters

[0090]

[0091] The high-temperature ...

Embodiment 2

[0098] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The technical data of lignite are shown in Table 1:

[0099] Table 1: Technical data of lignite:

[0100]

[0101] The amount of lignite coal is designed to be 110t / h, and it enters the dryer through the feeder, and the moisture Mt of the dried lignite is ≤ 10%, and then enters the pyrolysis furnace for pyrolysis.

[0102] Semi-coke is produced after lignite pyrolysis, the output is 60t / h, the semi-coke outlet temperature is 800°C, and the semi-coke parameters are as follows:

[0103] Table 2: High temperature semi-coke parameters

[0104]

[0105] The high-temperature semi-coke and the raw coal in the raw coal bunker enter the coal mill at a ratio of 1:2. The raw coal parameters in the raw coal bunker are as follows:

[0106] Table 3 Basic data of raw coal in raw coal bunker

[0107]

[0108] After entering the c...

Embodiment 3

[0112] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The technical data of lignite are shown in Table 1:

[0113] Table 1: Technical data of lignite:

[0114]

[0115] The amount of lignite coal is designed to be 100t / h, and it enters the dryer through the feeder, and the moisture Mt of the dried lignite is ≤ 10%, and then enters the pyrolysis furnace for pyrolysis.

[0116] Semi-coke is produced after lignite pyrolysis, the output is 60t / h, the semi-coke outlet temperature is 750°C, and the semi-coke parameters are as follows:

[0117] Table 2: High temperature semi-coke parameters

[0118]

[0119]

[0120] The high-temperature semi-coke and the raw coal in the raw coal bunker enter the coal mill at a ratio of 1:0.5. The raw coal parameters in the raw coal bunker are as follows:

[0121] Table 3 Basic data of raw coal in raw coal bunker

[0122]

[0123] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com