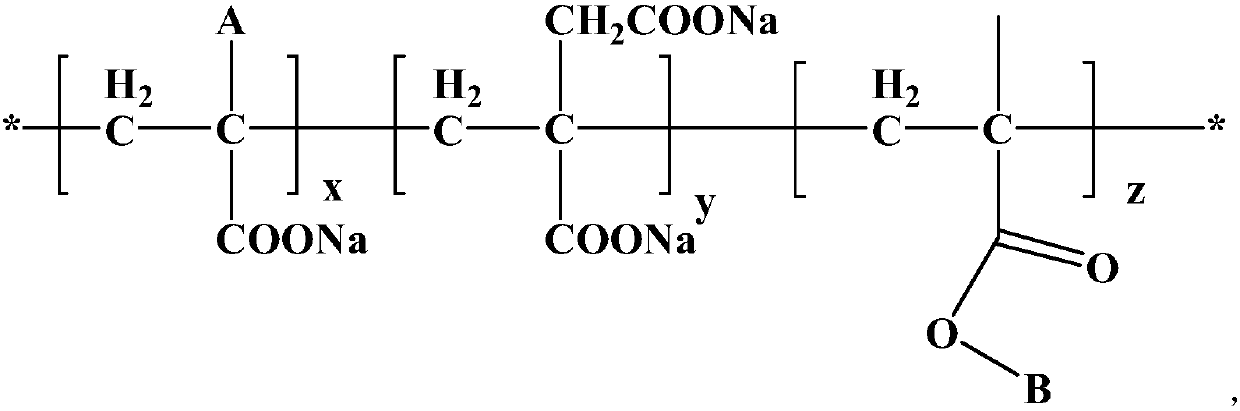

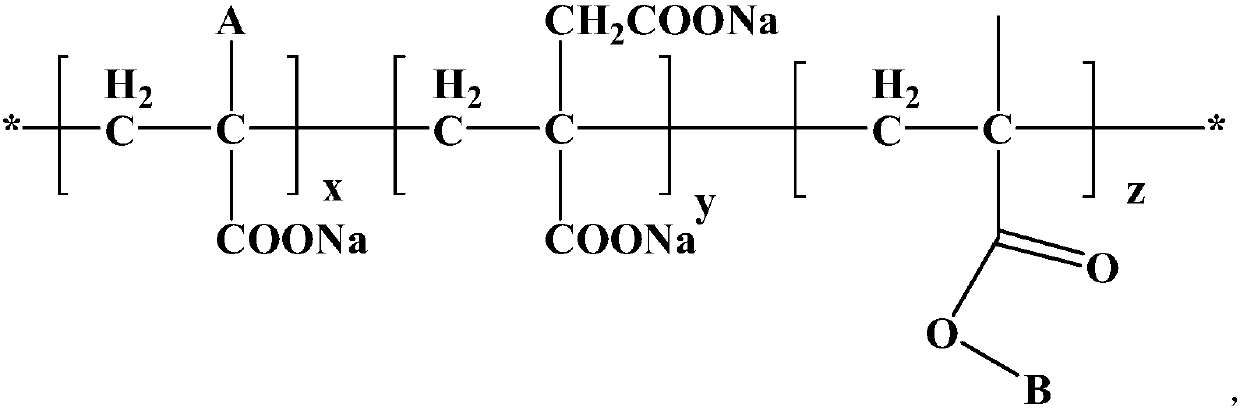

Waterborne high molecular ceramic pigment grinding aid dispersing agent as well as preparation method and application thereof

A technology of water-based polymers and ceramic pigments, applied in applications, household utensils, inks, etc., can solve the problems of late water-based polymer dispersants, less dispersant chain groups, and unserialized products, so as to improve grinding efficiency , reduced particle size, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

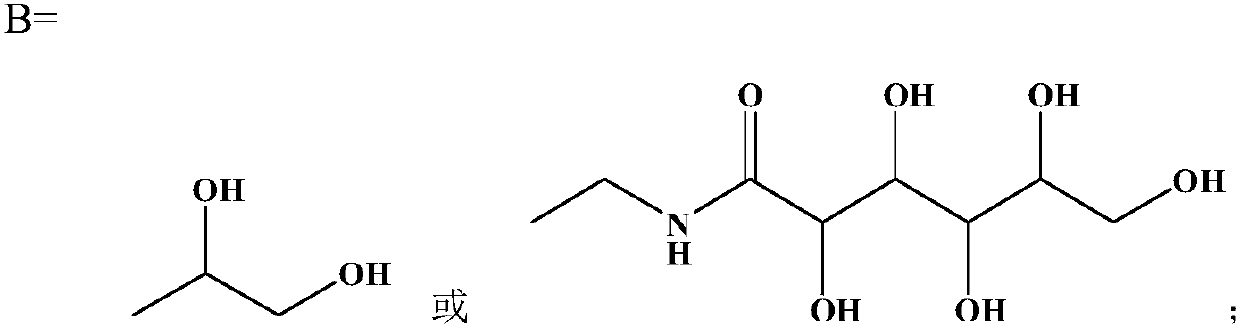

Method used

Image

Examples

Embodiment 1

[0041] Add commercially available glycidyl methacrylate (4.95g) into 50ml of distilled water, and reflux for 9 hours at a temperature of 95°C to obtain a clear solution. Freeze-dry to obtain a white solid that is the monomer GB1.

[0042] Acrylic acid (4g; 2eq), itaconic acid (3.6g; 1eq) and monomer GB1 (0.4g; 0.1eq) were added to a 100ml round bottom flask, distilled water (17ml) was added to dissolve, and then The initiator ammonium persulfate aqueous solution (1.5 wt %; 120 mg) was gradually added dropwise over 25 minutes. After keeping at 85°C for two hours, a viscous liquid was obtained, which was immediately neutralized with a 10mol / L sodium hydroxide solution in an ice bath to obtain a water-based polymer ceramic pigment grinding aid dispersant S1 , The number average molecular weight is 10430.

Embodiment 2

[0044] Monomer GB1 was obtained according to the method in Example 1. Acrylic acid (4g; 2eq), itaconic acid (3.6g; 1eq) and monomer GB1 (0.8g; 0.2eq) were added to a 100ml two-necked round-bottomed flask, distilled water (18ml) was added to dissolve, and then The initiator ammonium persulfate aqueous solution (1.4wt%; 118 mg) was gradually added dropwise under the conditions, and the time used for the dropwise addition was 30 minutes. After keeping at 85°C for two hours, a viscous liquid was obtained, which was immediately neutralized with a 10mol / L sodium hydroxide solution in an ice bath to obtain a water-based polymer ceramic pigment grinding aid dispersant S2 , The number average molecular weight is 9508.

Embodiment 3

[0046] Monomer GB1 was obtained according to the method in Example 1. Methacrylic acid (3.3g; 2eq), itaconic acid (2.5g; 1eq) and GB1 (0.3g; 0.1eq) were added to a 100ml two-neck round-bottomed flask, distilled water (10ml) was added to dissolve, and then the The initiator ammonium persulfate aqueous solution (3wt%; 183mg) was gradually added dropwise under the condition of 25 minutes. After keeping at 78°C for one and a half hours, a viscous liquid was obtained, which was immediately neutralized with a 10mol / L sodium hydroxide solution in an ice bath to obtain a water-based polymer ceramic pigment grinding aid dispersant S3 , The number average molecular weight is 8560.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com