Patents

Literature

35results about How to "Improve particle fineness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

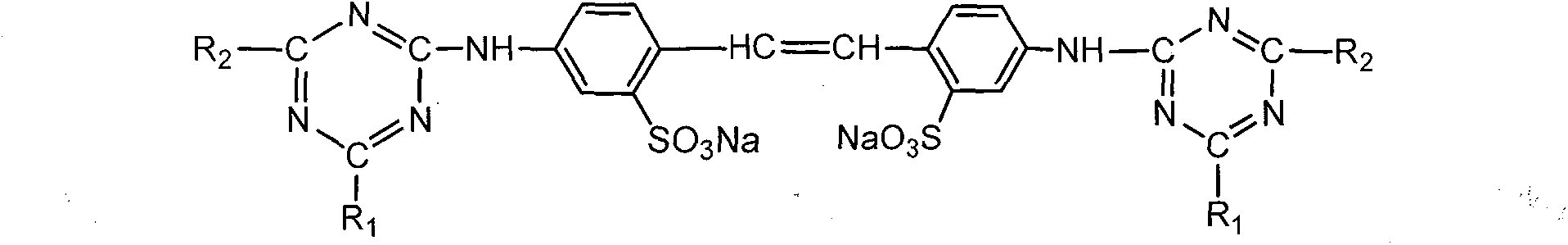

High-dispersivity fluorescent whitening agent and preparation method thereof

ActiveCN101760048AImprove particle finenessGood dispersionStyryl dyesDetergent dyesInorganic saltsWhitening Agents

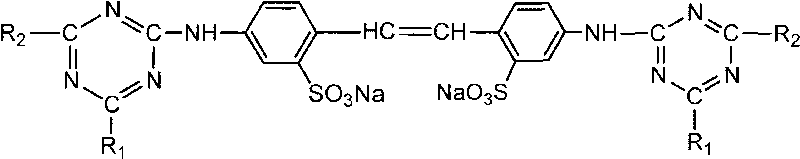

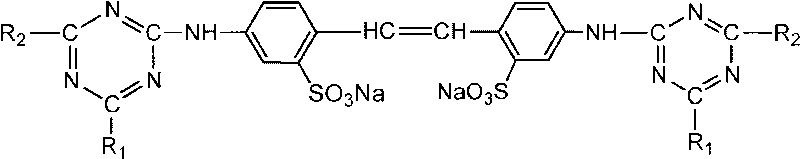

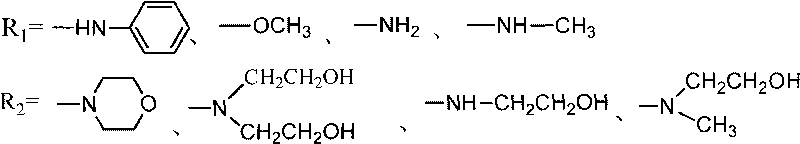

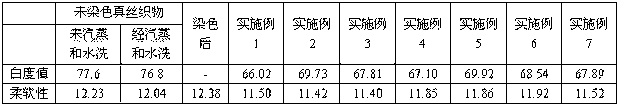

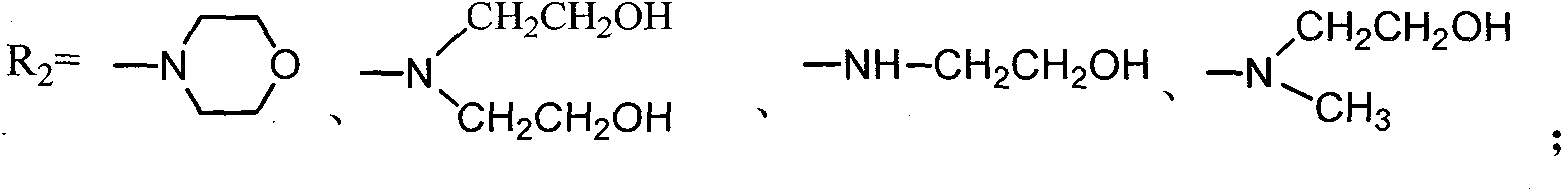

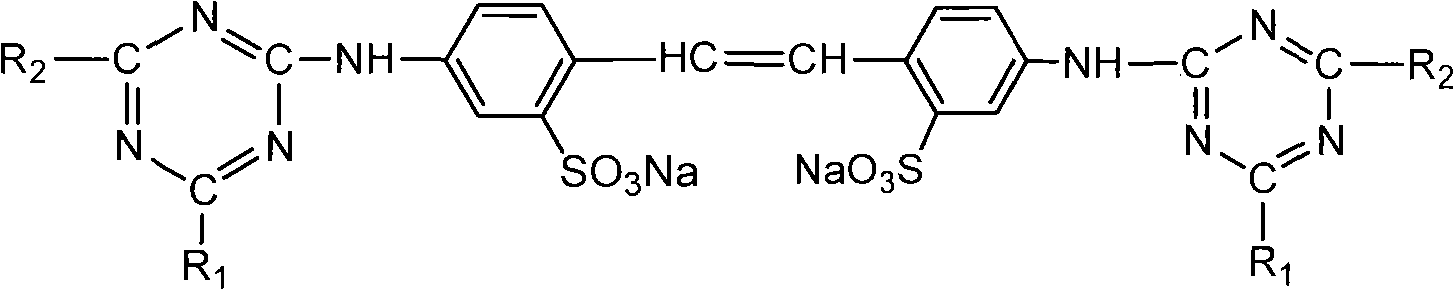

The invention provides a high-dispersivity fluorescent whitening agent, which comprises the following ingredients in percentage by weight: 20 to 45 parts of pure products converted from fluorescent whitening agent products represented by the following general formula or crude products with the fluorescent whitening agent, 2 to 30 parts of dispersing agents, 3 to 20 parts of inorganic salt and 2 to 10 parts of inorganic base. Water is added into the ingredients to be prepared into pulp with the solid content between 20 and 45 percent, the ingredients are ground into materials with the grain fineness smaller than or equal to 5 mm, and the grain type fluorescent whitening agent with the piling density larger than or equal to 450 kg*m<-3> is obtained through spraying drying. The high-dispersivity fluorescent whitening agent product prepared by the invention has the advantages of convenient use, long storage time, easy transportation and no dust pollution, and has high dispersivity in water, the dispersivity can be more than or equal to 50 percent in 2 min and can be more than 80 percent in 10 min, and the high-dispersivity fluorescent whitening agent can be widely used in washing industry. Formula is shown as the accompanying drawing.

Owner:山西晋光化工有限公司

Method for superfine grinding of walnut dregs by wet process by employing ball mill

The invention discloses superfine grinding technology of walnut dregs by a wet process, belonging to the technical field of agricultural products and food processing. The method comprises the process flows of coarse grinding of walnut dregs, mixture of coarsely ground powder of walnut dregs and water and superfine grinding by the wet process by a ball mill, etc. The temperature is not raised in the process of grinding; therefore, the nutrient components of the walnut dregs can not be damaged. In terms of kg / L, the ratio of coarse powder of walnut dregs to water is 1:(8-14). The parameters of the superfine grinding technology by the wet process by the ball mill are as follows: the ball-to-powder weight ratio is (1-6):10, the media are phi10mm zirconia balls, the milk grinding time is 30-120min and d50 of the walnut milk granule is 6-17mu m. The superfine grinding technology lays the foundation for subsequent preparation of walnut powder through spray drying and the application range of the superfine grinding technology in the food industry is broadened.

Owner:XINJIANG UNIVERSITY

Environment-friendly paste discharge agent for textile printing and preparation method thereof

ActiveCN102704292ANon-oxidizingNon-reducibleTransportation and packagingMixingSolubilityTextile printer

The invention discloses an environment-friendly paste discharge agent for textile printing and a preparation method thereof. The environment-friendly paste discharge agent comprises the following components in parts by weight: 30-60 parts of decamethyl cyclopentasiloxane, 40-70 parts of thiourea dioxide, 1-3 parts of surfactant and 3-6 parts of glycerin. The preparation method comprises the steps: putting the decamethyl cyclopentasiloxane into a ball grinder container; adding the surfactant to be uniformly dispersed or dissolved and uniformly agitated; and then adding the thiourea dioxide into the ball grinder container to blend and grind for 1-3 hours. Specific liquid compound decamethyl cyclopentasiloxane as a disperse medium and the thiourea dioxide are not subjected to chemical reaction; With the environment-friendly paste discharge agent provided by the invention, contact of the thiourea dioxide with the external water and air is isolated; the stability of the thiourea dioxide is improved; the discharge effect is excellent; and the problems of low solubility, poor dispersible uniformity in discharge pulp, poor net permeability and insufficient development of the discharge action caused by common thiourea dioxide used as the discharge agent are overcome.

Owner:HAINING GREEN SHIELD TEXTILE TECH CO LTD

Method for preparing mashed purple sweet potato solid beverage

InactiveCN101889710AIncrease contentImprove solubilityFood preparationPre treatmentAdditive ingredient

The invention discloses a method for preparing mashed purple sweet potato solid beverage. The method comprises the following steps of: pretreating purple sweet potatoes; cooking the pretreated purple sweet potatoes; preparing the cooked purple sweet potatoes into mashed potatoes; performing saccharification and glue milling on the mashed potatoes; and packaging to obtain a mashed purple sweet potato solid beverage product. In the method, the purple sweet potatoes are taken as a raw material and treated by a specific process so that the starch content of the raw material can be reduced, the soluble solid content, in particular the small-molecule sugar content of the raw material is increased, the solubility of the mashed purple sweet potatoes is enhanced and reconstitution performance is improved; and moreover, the method has the advantages of simple process flow, low requirement on equipment and capability of keeping constituents such as anthocyanin and the like of the purple sweet potatoes to the maximum extent, keeping the bright color of a prepared product and the inherent purple color of the raw material and making the product have high reconstitution performance and delicious flavor.

Owner:XIHUA UNIV +2

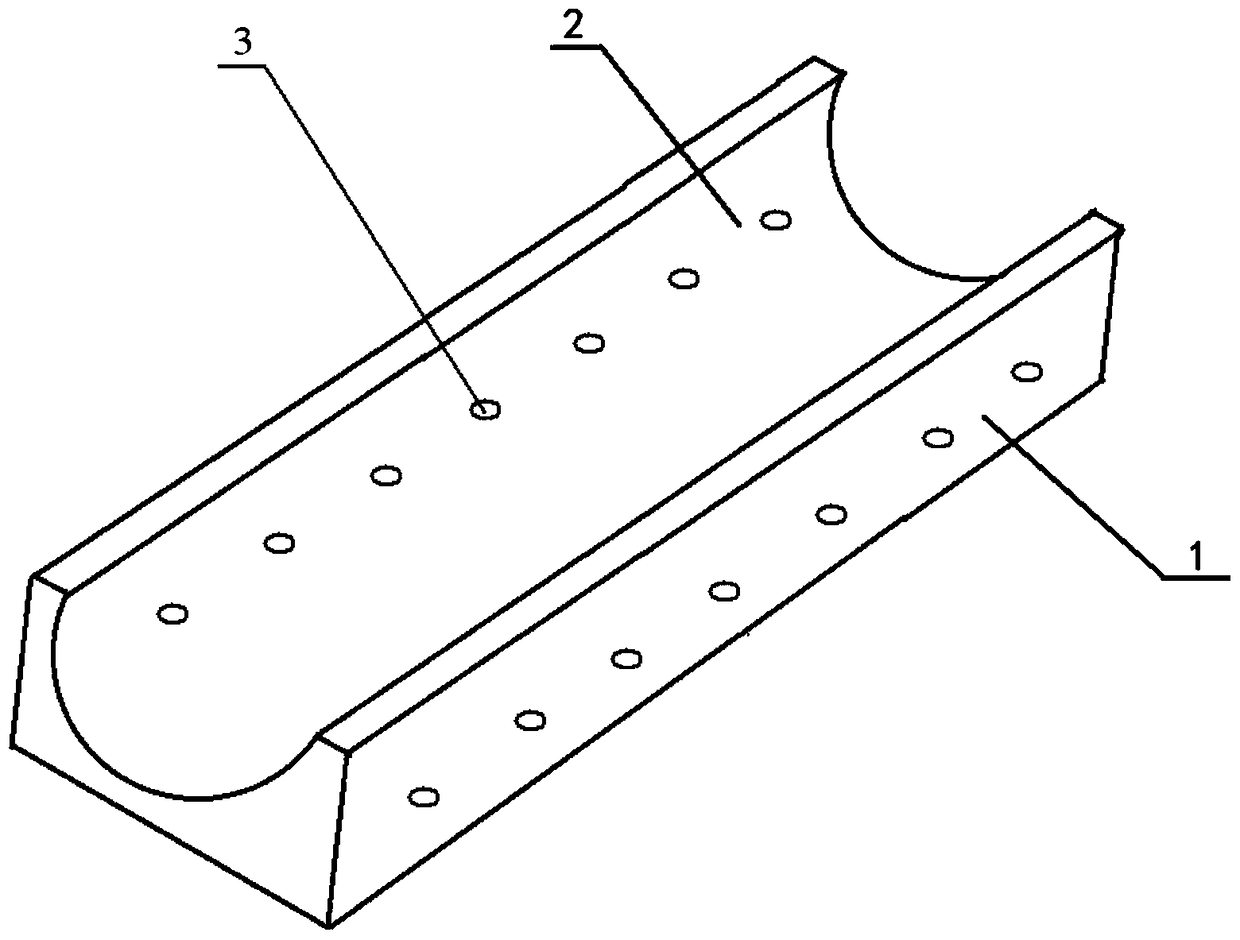

Preparation method for active dendrobium candidum superfine powder

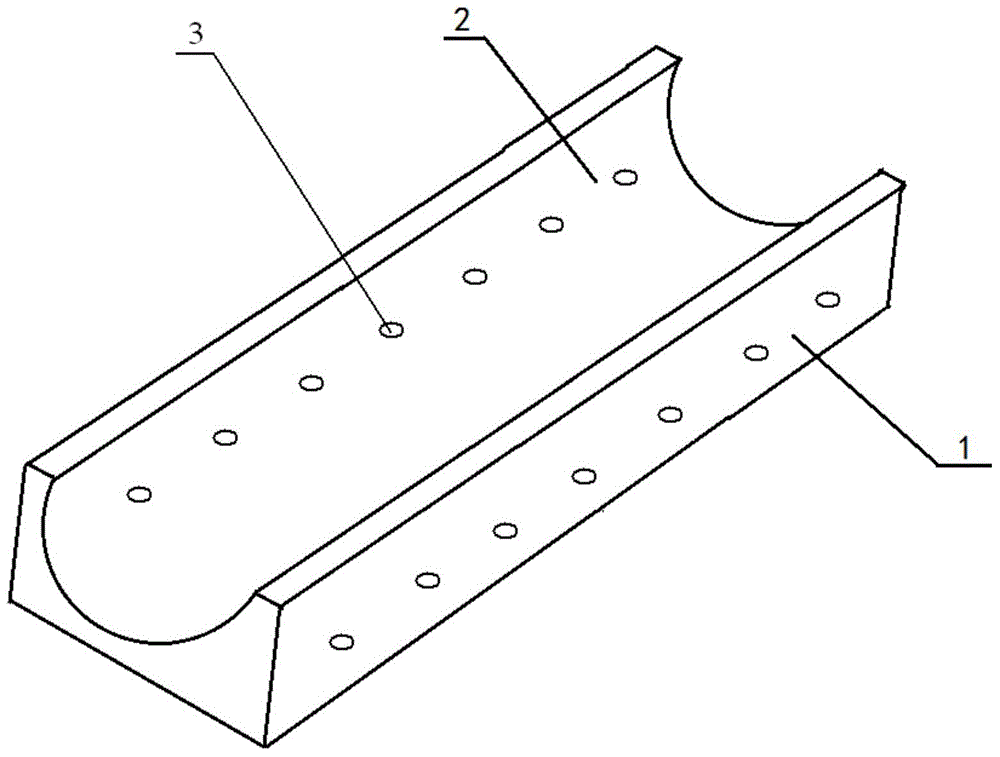

ActiveCN104906384AReduce contact areaIncrease pre-freezing and heat transfer effectPowder deliveryPlant ingredientsMicrometerSmall hole

The invention discloses a preparation method for active dendrobium candidum superfine powder. The preparation method comprises steps: first, leaves of harvested fresh dendrobium candidum are removed, and washing and draining are carried out; second, punching is carried out, the dendrobium officinale is fixed on a die, the die is placed on a shelf of a vacuum drying container, cooling is carried out, the die is a cube-shaped metal die body (1) with an upper surface equipped with a half-cylindrical groove (2), and small holes (3) are arranged in the die body; third, vacuum-pumping is carried out; fourth, the shelf is heated, the temperature is risen to 0 DEG C, the pressure intensity is kept at 20-100Pa, drying is carried out, the material temperature is risen from 0 DEG C to 20 DEG C, the pressure intensity is kept at 10-20Pa, drying is carried out, the material temperature is risen from 20 DEG C to 40 DEG C, the pressure intensity is kept within 10Pa, drying is carried out, pressurization to a normal pressure is carried out; fifth, low temperature air-flow crushing is carried out, and active dendrobium candidum superfine powder is obtained and more than 95% of active dendrobium candidum superfine powder has a particle size of being less than 20 micrometers. The freeze-drying rate is high, freeze-drying time is saved, energy consumption is lowered, the product has a small particle size and is easy to dissolve and absorb, and the bioavailability is high.

Owner:ZHEJIANG JIANFENG HEALTH TECH

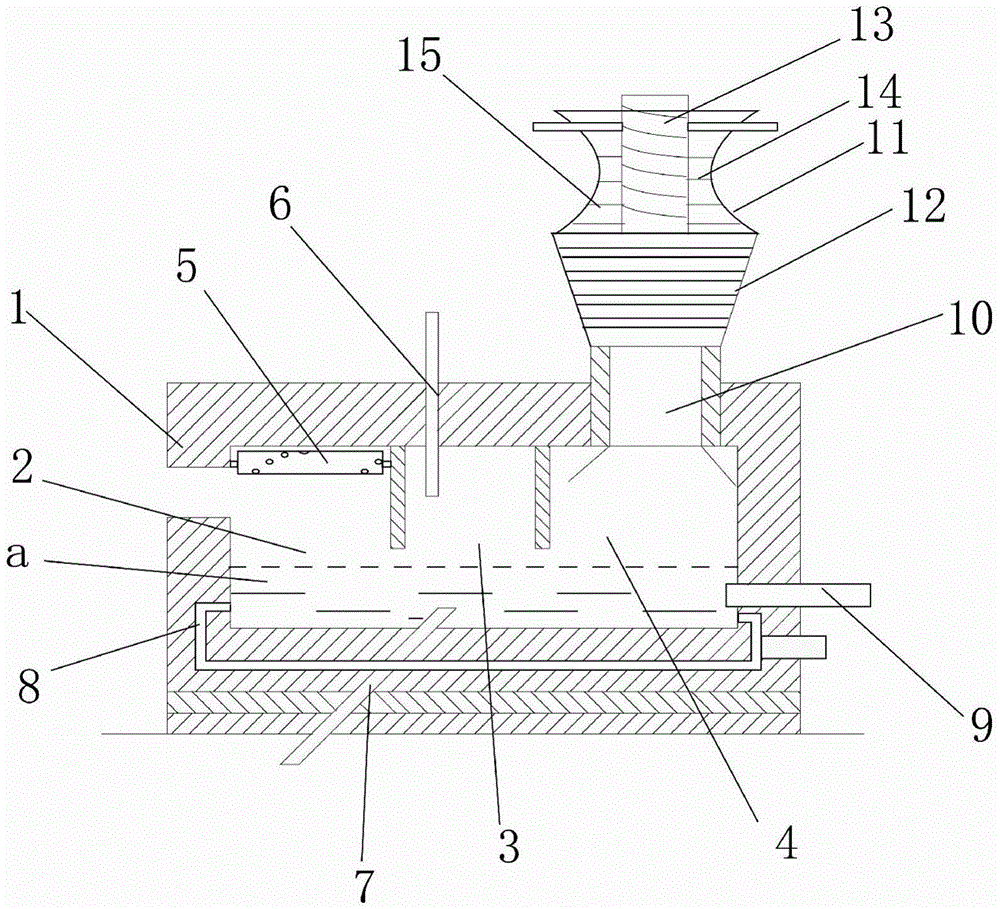

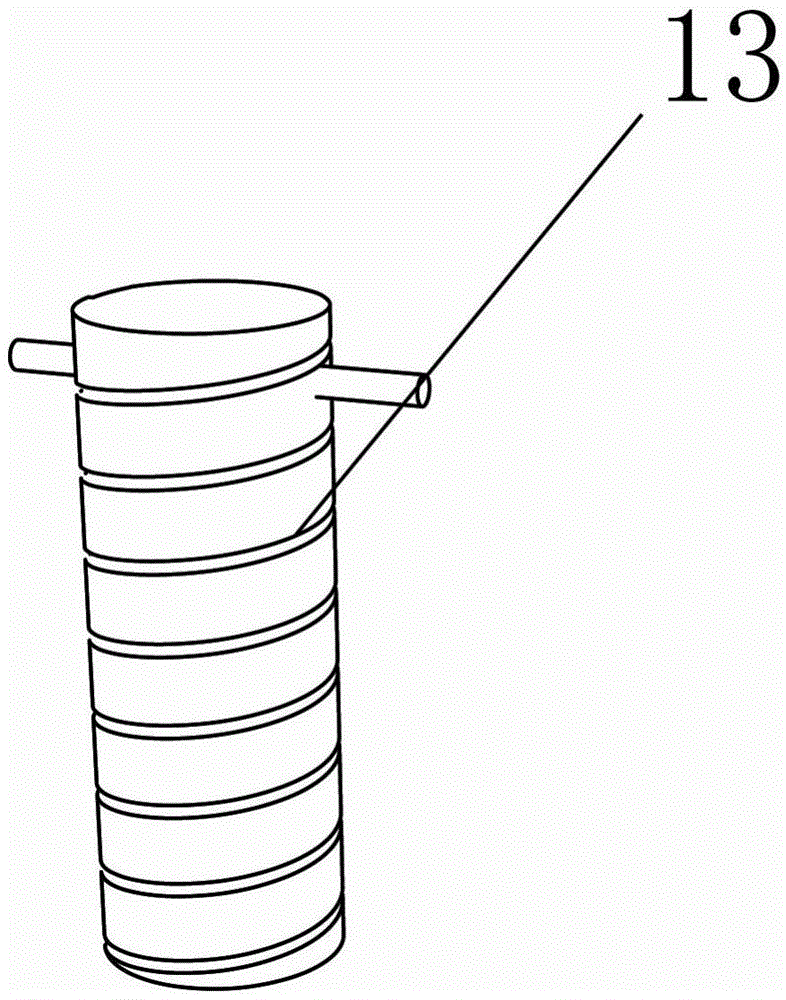

Powder pulverizer

The invention discloses a powder pulverizer. The powder pulverizer comprises a casing, a motor, a primary pulverizing device, a pulverizing barrel, a pulverizing core and a fan, wherein the motor is fixed on the casing; the pulverizing barrel is arranged above the motor; the fan is arranged at the bottom of the pulverizing barrel; the upper end of the fan is connected with the pulverizing core; the upper end of the pulverizing core is connected with the primary pulverizing device; the pulverizing barrel and the pulverizing core rotate relatively, the pulverizing barrel and the pulverizing core are conical, but the conicity of the pulverizing barrel is smaller than that of the pulverizing core, and the pulverizing barrel and the pulverizing core are coaxially arranged. The powder pulverizer can pulverize large materials by the aid of a knife or a hammer, the adaptability to raw materials is improved, the materials can be pulverized by means of the conical pulverizing barrel and the conical pulverizing core which rotate relatively, the particle fineness is high, the pulverizing speed is high, and discharge of the materials is facilitated.

Owner:SUZHOU KAIYE METAL PROD

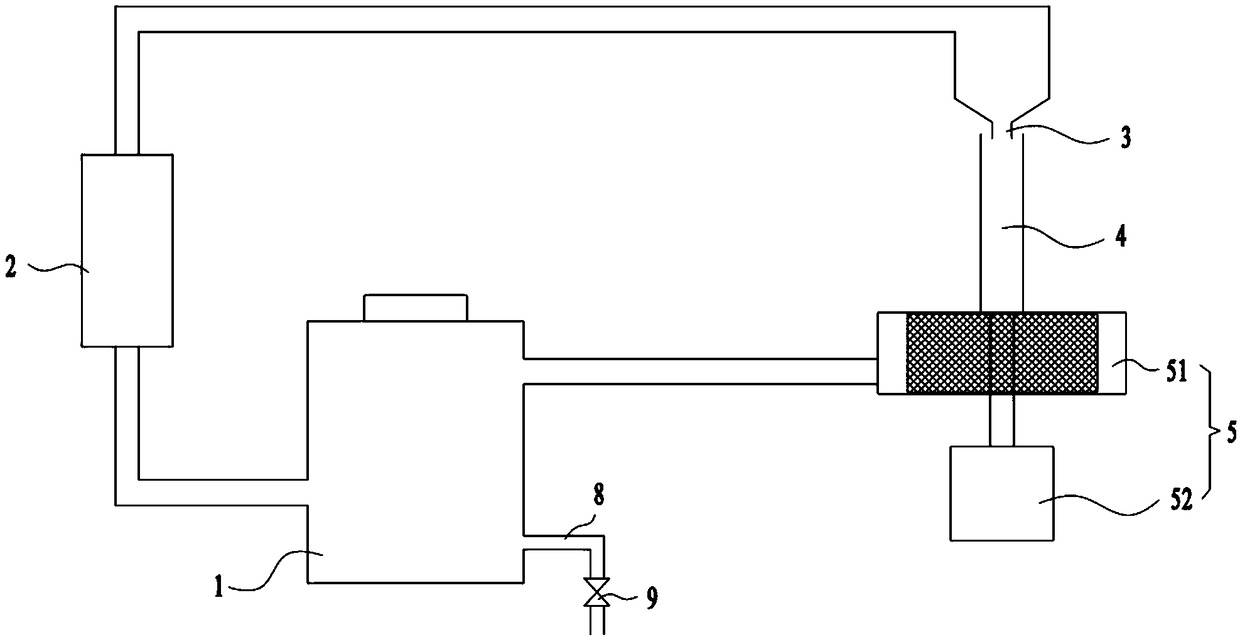

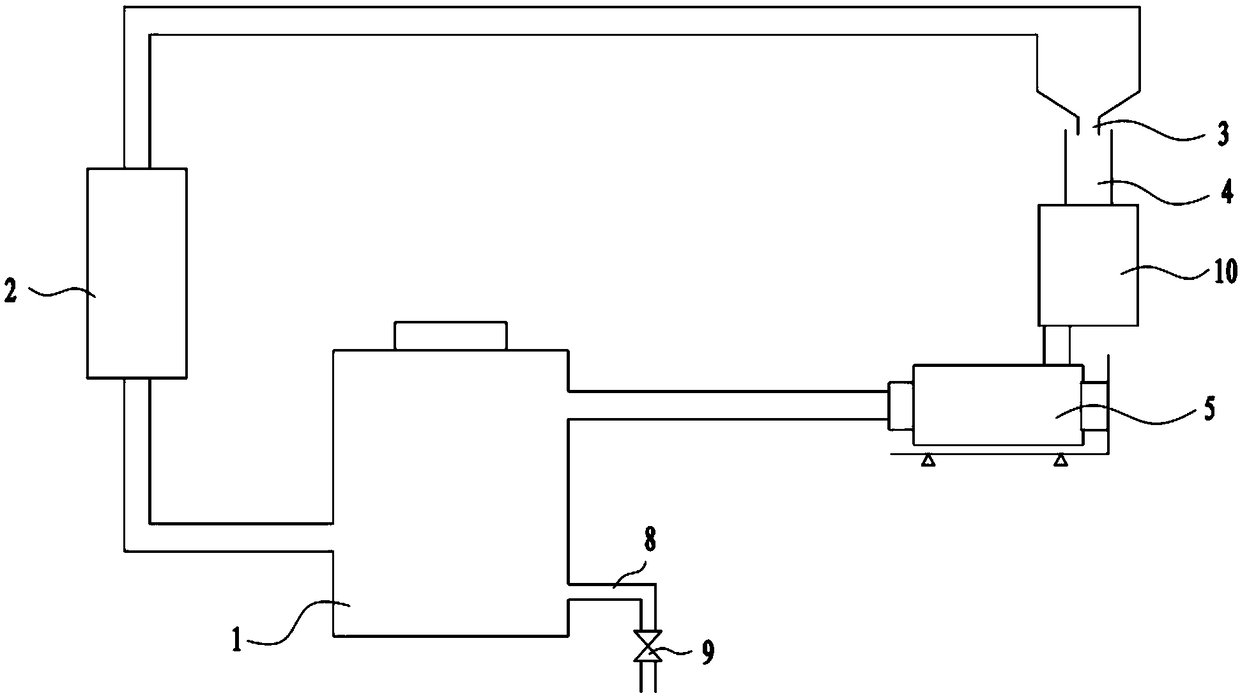

Solid-liquid mixing equipment and solid-liquid mixing method

InactiveCN108786509AUniform treatmentAvoid over crushingFlow mixersTransportation and packagingSpray nozzleEngineering

The invention discloses solid-liquid mixing equipment. The solid-liquid mixing equipment comprises a storage tank, a pump body, a spray nozzle, a material receiving pipe and a shearing device, whereina material inlet of the pump body is connected with the storage tank; the tail part of the spray nozzle is connected with a material outlet of the pump body; one end of the material receiving pipe islocated in a feed liquid spraying direction of the spray nozzle; a material inlet of the shearing device is connected to the other end of the material receiving pipe, and a material outlet of the shearing device is connected to the storage tank. The invention also discloses a solid-liquid mixing method. The solid-liquid mixing method comprises the following steps: adding to-be-mixed feed liquid in the storage tank; spraying the feed liquid from the spray nozzle under the driving of the pump body; enabling the feed liquid to enter the shearing device through the material receiving pipe, and enabling the feed liquid to flow into the storage tank after shearing and mixing. According to the solid-liquid mixing equipment disclosed by the invention, the storage tank is separated from the shearing device, solid-liquid mixed materials can be uniformly treated, a phenomenon of doping of large particles cannot occur, and particles can also be prevented from being excessively smashed; through the arrangement of the spray nozzle, ejected fluid is enabled to quickly enter the material receiving pipe, so that negative pressure is formed at the periphery of a pipe opening of the material receiving pipe, and materials can be sucked into the material receiving pipe.

Owner:哈尔滨万鑫石墨谷科技有限公司

Method for preparation of dimethyl ether

ActiveCN102125854AImprove particle finenessImprove performanceMetal/metal-oxides/metal-hydroxide catalystsEther preparationRare earthColloid

The invention relates to a method for the preparation of dimethyl ether, which comprises the steps of: using the intermediate product of a copper-zinc-aluminum methanol synthesis catalyst, i.e. the carbonate mixture, as the component of the methanol synthesis catalyst, using rare earth modified gamma-alumina with low temperature activity as the component of the methanol synthesis catalyst, sufficiently mixing the two components according to the method based on colloidal sedimentation and mechanical mixing, and activating the mixture to obtain dimethyl ether. The method of the invention is simple in process and ensures the repeatability in catalyst preparation; the catalyst prepared according to the method has small particle size and high specific surface area; and the catalyst has high activity owing to tight contact and strong synergistic effect between the components.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Quartz powder used for manufacturing ceramic

The invention discloses quartz powder used for manufacturing ceramic. According to the invention, quartz sandstone is subjected to coarse crushing for the first time through an impact crusher; coarsely-crushed and unscreened quartz sandstone is transferred to a jaw crusher for fine crushing for the second time; during fine crushing, the size of the discharge outlet of the jaw crusher is adjusted to control the particle size of a discharged material, so quartz sands with uniform particle shape are obtained; the quartz sands obtained by crushing for two times are subjected to fine crushing for the third time through a cone crusher; the crushed quartz sands are screened through a sieve of the cone crusher, so quartz particles are obtained; impurities in the quartz powder obtained by crushingand grinding can be effectively subjected to magnetic separation for iron removal; the quartz powder with high purity and applicable to manufacturing of the ceramic is prepared after acid pickling, water washing and drying; and the quartz powder prepared by using the method provided by the invention has the advantages of high purity, fine particles and uniform particle dispersion.

Owner:滁州方大矿业发展有限公司

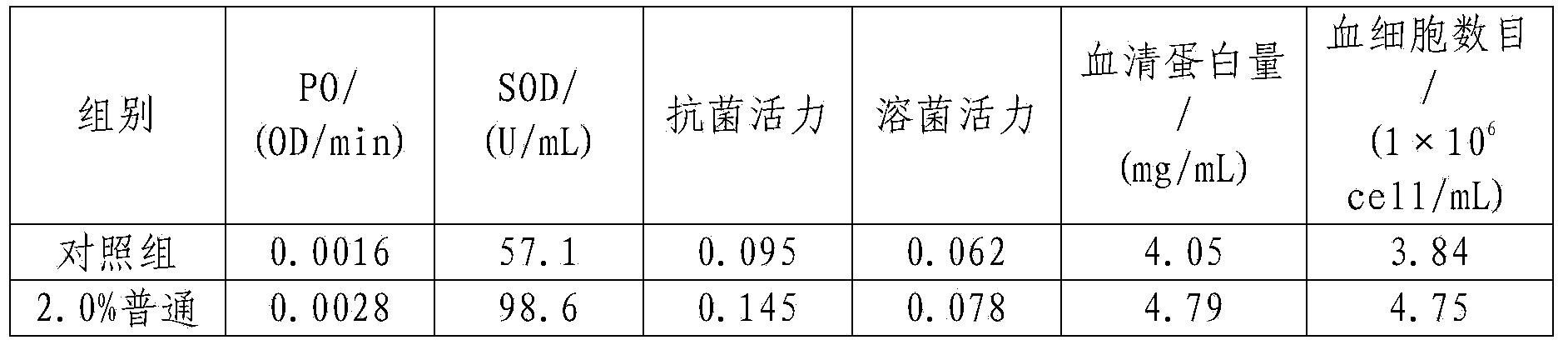

Astragalus and ginseng powder submicron powder, and manufacturing method and application thereof

InactiveCN103784494AIncrease productionImprove physiological activityAntibacterial agentsPowder deliverySide effectPrawn

The invention relates to the field of fishery medicine agents, in particular to astragalus and ginseng powder submicron powder, and a manufacturing method and application of the astragalus and ginseng powder submicron powder. The astragalus and ginseng powder submicron powder is composed of, by weight, 40% to 50% of astragalus, 25% to 35% of ginseng and 25% to 35% of radix glycyrrhizae. The astragalus and ginseng powder submicron powder is reasonable in formula, capable of completely releasing effective constituents, small in additive amount, quick in cure effect, obvious in effect, free of toxic and side effect, easy to implement, and suitable for large-scale production. Long-term breeding experimental results show that prawns are bred through fodders with the astragalus and ginseng powder submicron powder prepared through the method, the growth performance and the non-specificity immune index of the prawns are remarkably improved, the consumption can be remarkably reduced by three to four times compared with ordinary coarsely-ground traditional Chinese medicine preparations in the current market, and therefore the effects of promoting growth and enhancing immunity are achieved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

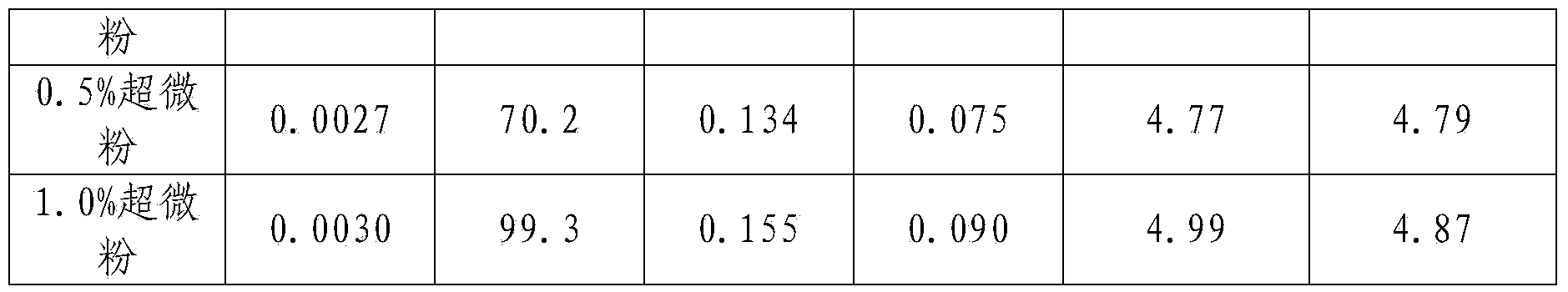

Processing method of ready-to-eat oat and surimi crispy chips

InactiveCN105595231AEvenly distributedImprove solubilityFood thermal treatmentFood homogenisationProcess engineeringNutritional quality

The invention discloses a processing method of ready-to-eat oat and surimi crispy chips. The method comprises the steps of oat smashing, high pressure homogenizing to prepare oat pulp, surimi chopping, extruding and curing forming and packing. The oat pulp is prepared through a high pressure homogenization technology, and the problems that traditional oat flour is prone to caking and poor in solubility in the surimi chopping process can be solved; auxiliaries are added in the surimi chopping process, rapid curing forming of surimi is achieved through a rapid extruding and curing forming technology, and destruction of traditional high-temperature water-bath heating to the nutritional quality of a surimi product is avoided. The obtained ready-to-eat oat and surimi crispy chips not only maintain the nutrition and quality of oat and surimi, but also have a good flavor and eating mouthfeel, can accord with the requirements of consumers on the diversity and nutrition property of the surimi product and show a promising future in development.

Owner:FUJIAN AGRI & FORESTRY UNIV

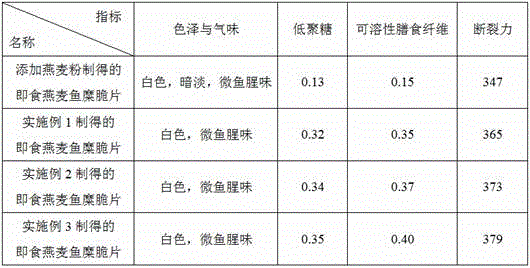

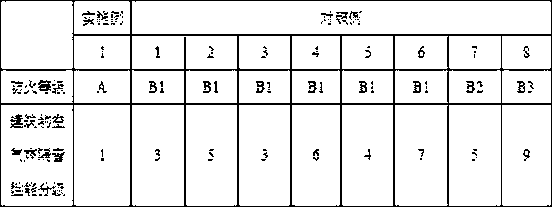

Environment-friendly and fireproof building sound insulation material and preparation method thereof

The invention relates to an environment-friendly and fireproof building sound insulation material and a preparation method thereof. The environment-friendly and fireproof building sound insulation material comprises modified epoxy resin E51, modified straws and modified starch, epoxy resin E51, hexahydrophthalic anhydride, modified ammonium polyphosphate, KH-560 coupling agents and dibutyltin dilaurate react to prepare the modified epoxy resin E51, ammonium polyphosphate, bisphenol A epoxy acrylate, acrylic acid, methyl acrylate, SE-10 emulsifying agents and 819 photoinitiators react to prepare the modified ammonium polyphosphate, straws, diphenylmethane diisocyanate, calcium carbonate, azodiisobutyronitrile and pentaerythritol react to prepare the modified straws, and amylopectin, acrylicacid, bisphenol A epoxy acrylate, water, SR-10 emulsifying agents and 819 photoinitiators react to prepare the modified starch. The environment-friendly and fireproof building sound insulation material has excellent fire prevention and sound insulation performances.

Owner:郑州德威机械设备有限公司

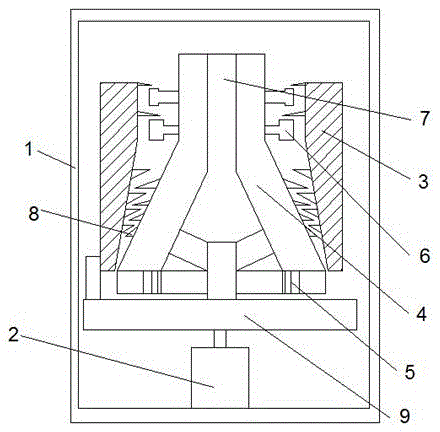

Device for preparing nanoscale antimony trioxide

InactiveCN104310473AHigh purityHigh particle finenessAntimony oxides/hydroxides/oxyacidsNanotechnologyEngineeringAntimony

The invention discloses a device for preparing nanoscale antimony trioxide. The device comprises an antimony white furnace and a reactor and is characterized in that a front chamber, a middle chamber and a rear chamber communicated with one another are arranged in an inner chamber of the antimony white furnace, a rotary air blower is arranged at the top of the front chamber, a bottom blowpipe and a top blowpipe are arranged in the middle chamber, the bottom blowpipe extends into antimony liquid, the top of the rear chamber is connected to the reactor, and a double-layer crystallizer is arranged at the top of the reactor.

Owner:GUANGXI GAOZHONG VALVE MFG

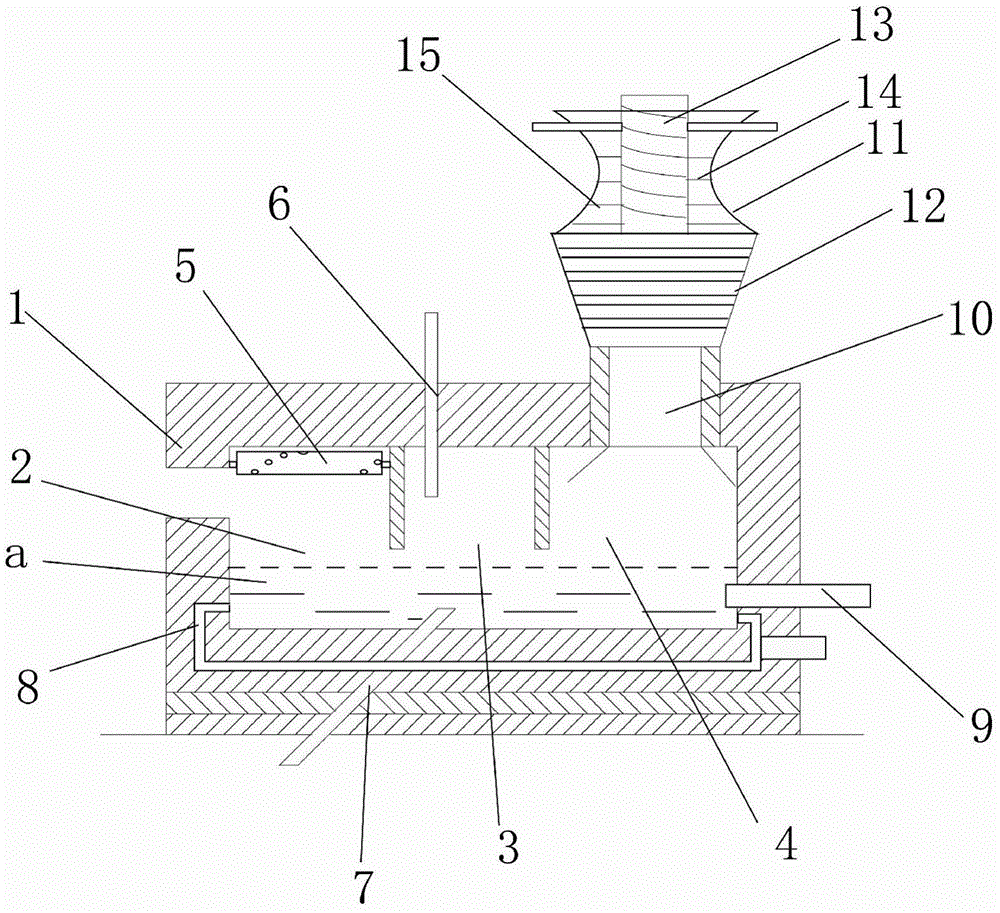

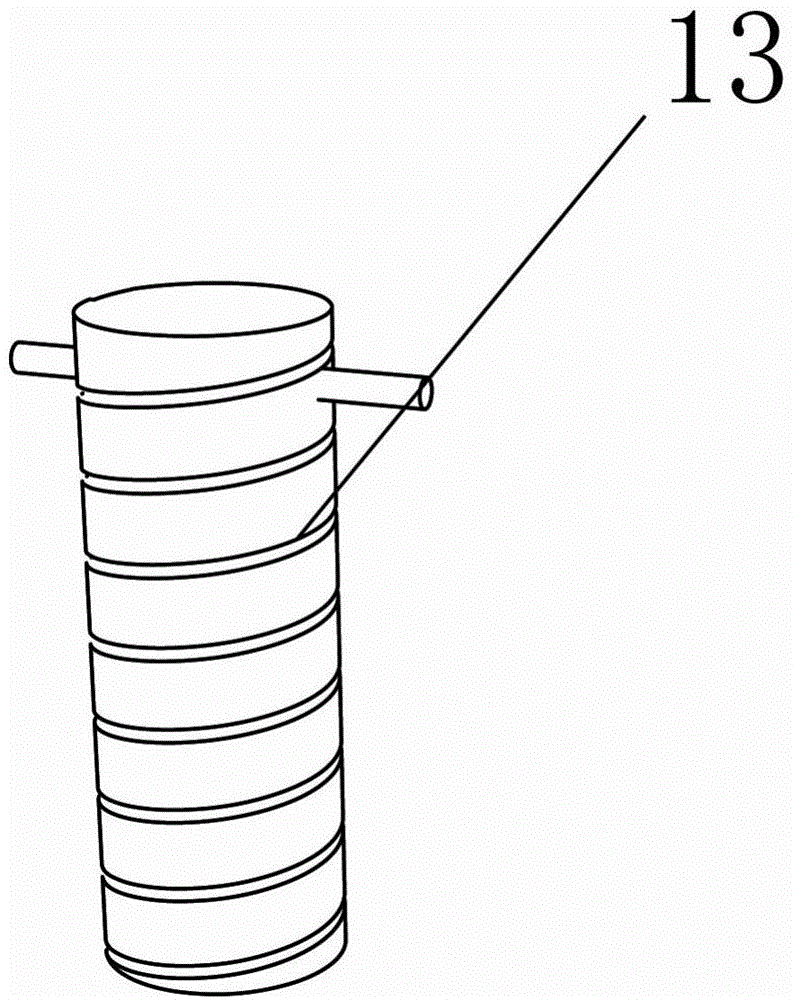

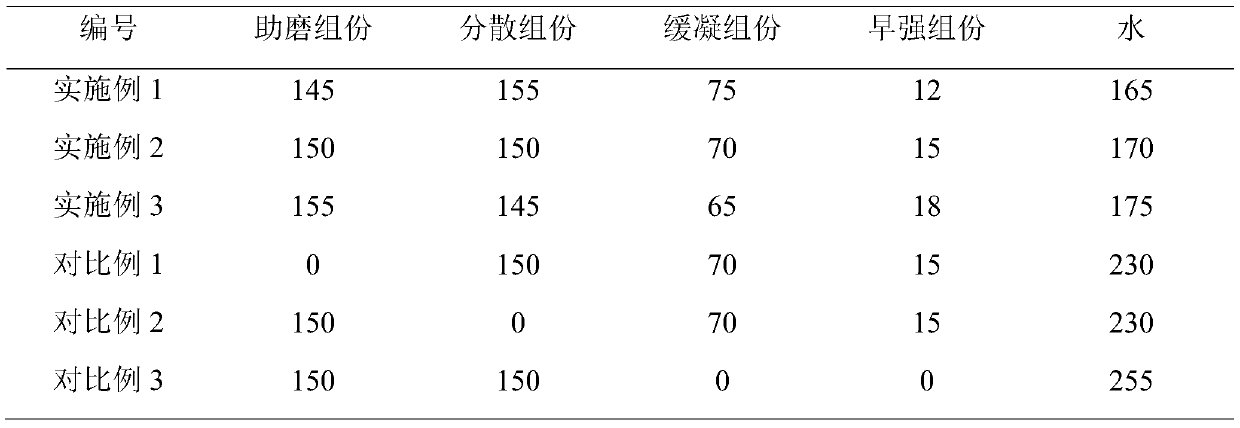

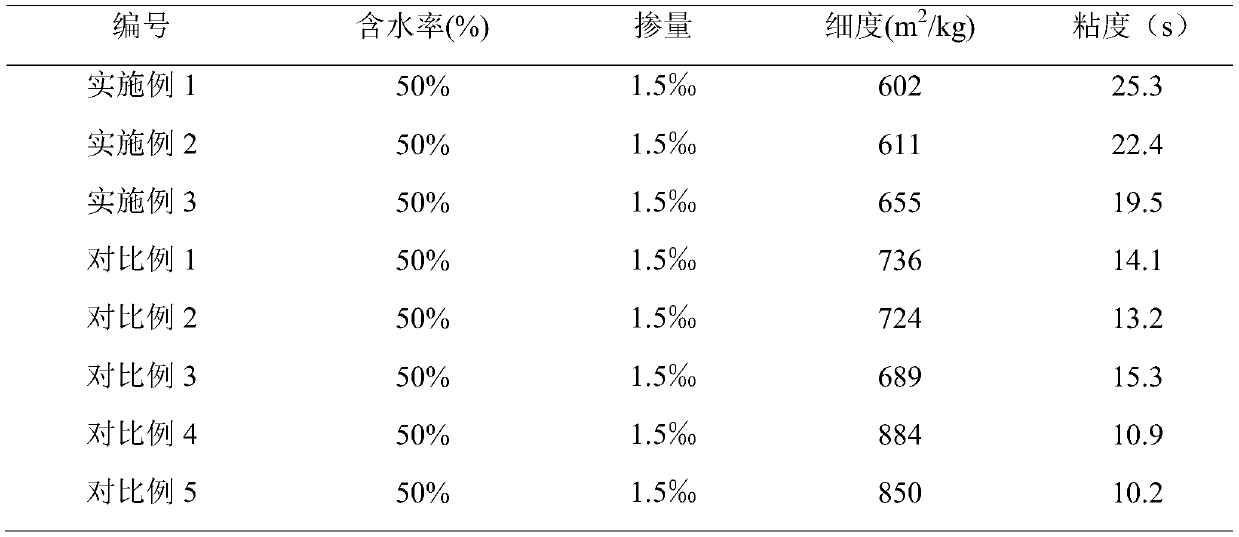

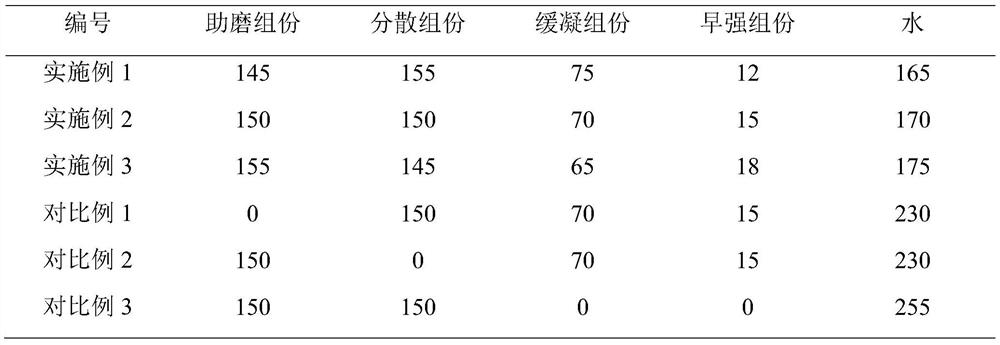

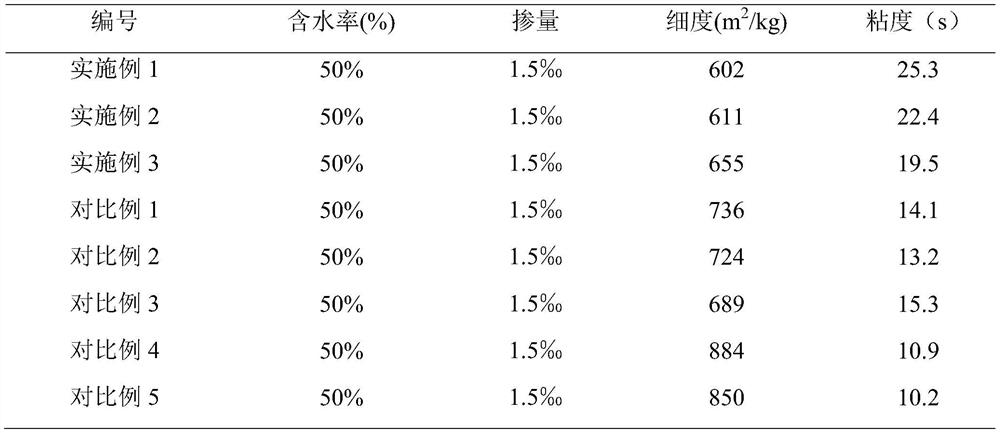

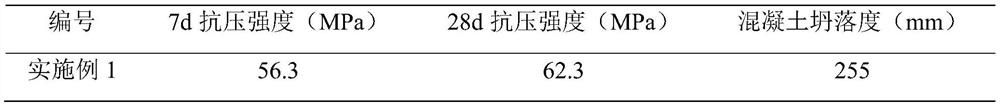

Compound functional aid for wet grinding of concrete waste residues and application thereof

The invention discloses a compound functional aid for wet grinding of concrete waste residues and application thereof. The compound functional aid comprises the following components in parts by mass:140-160 parts of a grinding aiding component, 140-160 parts of a dispersing component, 60-80 parts of a retarding component, 10-20 parts of an early0strength component and 160-180 parts of water. Thefunctional additive is specially designed for concrete waste residues, has multiple functions including a grinding aiding function, a dispersing function, a slump retaining (retarding) function, an early-strength promoting function and the like, and is in a liquid state at normal temperature, low in mixing amount and friendly to environment. When the compound functional aid is used for wet grinding of concrete waste residues, wet grinding efficiency can be effectively improved, obtained waste residue slurry is uniformly and stably dispersed, has extremely high particle fineness and extremely high activity and is easy to store and convey, the early strength and the working performance of concrete can be effectively improved after the waste residue slurry replaces admixtures used for concrete production, and high engineering application value is obtained.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

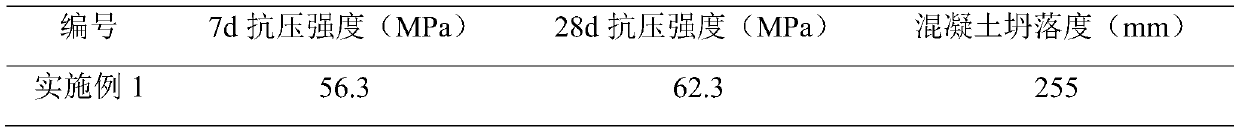

Regenerated UHPC cement concrete and preparation method thereof

The invention discloses regenerated UHPC cement concrete and a preparation method thereof, and belongs to the field of building materials. The concrete comprises the following components in parts by weight: 100 parts of recycled UHPC cement, 35-40 parts of water, 180-220 parts of fine aggregate, 280-350 parts of coarse aggregate and 0.5-0.8 part of a water reducing agent. The regenerated UHPC cement concrete is prepared by crushing, screening, grinding and chemically exciting and stirring waste UHPC, and the recycled UHPC cement concrete can be prepared by sequentially adding the raw materialsinto a stirrer according to the components and parts by weight of the concrete, stirring and curing. According to the preparation method, waste is changed into valuables, through the steps, the wasteultra-high performance concrete is processed into regenerated cement which can be reused, the use amount of ordinary Portland cement can be reduced, the environmental problem caused by the waste ultra-high performance concrete can be solved, and reasonable utilization of resources is achieved.

Owner:HUNAN UNIV

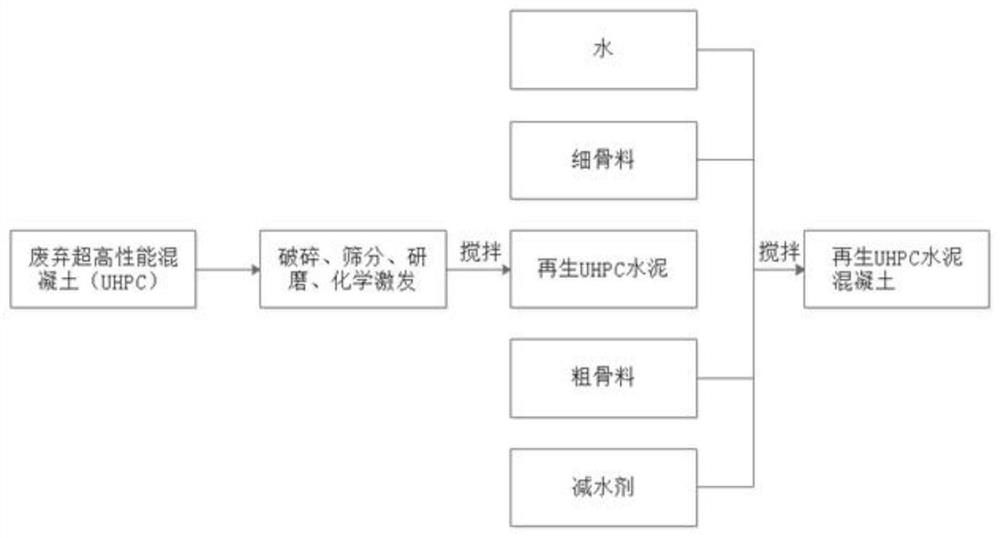

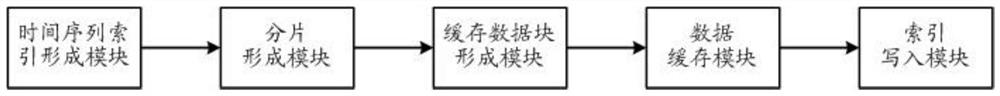

Big data-oriented data stream type caching method and system

PendingCN113806374AImprove particle finenessIncrease profitDatabase updatingSpecial data processing applicationsResource poolMinimum time

The invention relates to a big data-oriented data stream type caching method and system. The method comprises the following steps: completing timestamp marking of each item of record information in a data stream arriving at a system to form a time sequence index; selecting the minimum time limited by a pre-configured basic data volume, and performing slicing based on the time sequence index to complete automatic fragmentation processing of a data stream time section to obtain sub-data streams of a plurality of fragments; performing determinant conversion on the data information in the sub-data stream of each fragment according to a pre-configured cacheable data column, completing real-time compression of the same data column, and forming a cache data block; and allocating idle data stream cache resources in a pre-configured data stream cache resource pool according to the size of the cache data block, and writing the cache data block into the data stream cache resources. According to the invention, a high-performance cache mechanism for data access can be provided under the condition of ensuring that the original stream sequence is not changed.

Owner:上海健交科技服务有限责任公司

Method for preparation of dimethyl ether

ActiveCN102125854BImprove particle finenessImprove performanceMetal/metal-oxides/metal-hydroxide catalystsEther preparationRare earthColloid

The invention relates to a method for the preparation of dimethyl ether, which comprises the steps of: using the intermediate product of a copper-zinc-aluminum methanol synthesis catalyst, i.e. the carbonate mixture, as the component of the methanol synthesis catalyst, using rare earth modified gamma-alumina with low temperature activity as the component of the methanol synthesis catalyst, sufficiently mixing the two components according to the method based on colloidal sedimentation and mechanical mixing, and activating the mixture to obtain dimethyl ether. The method of the invention is simple in process and ensures the repeatability in catalyst preparation; the catalyst prepared according to the method has small particle size and high specific surface area; and the catalyst has high activity owing to tight contact and strong synergistic effect between the components.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

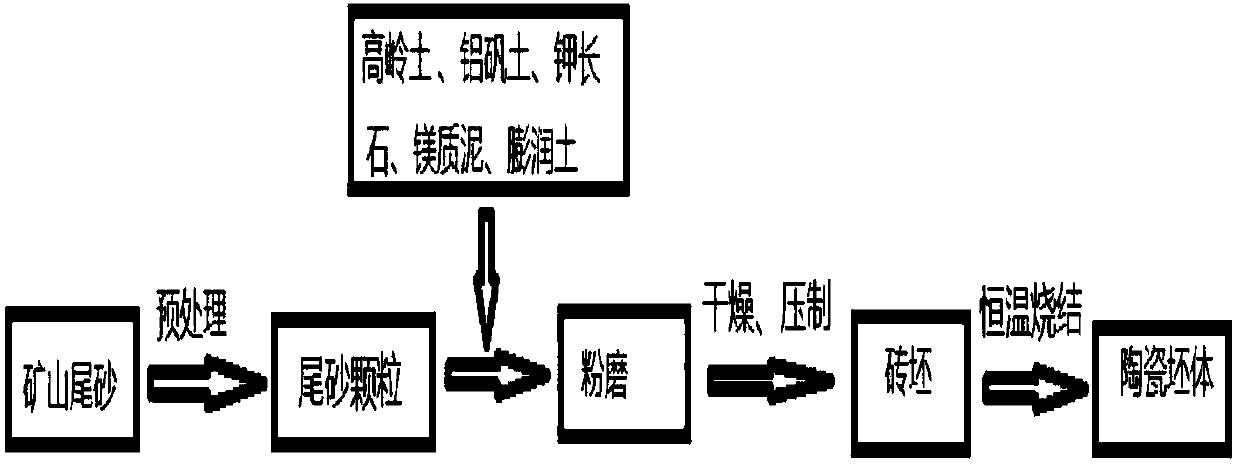

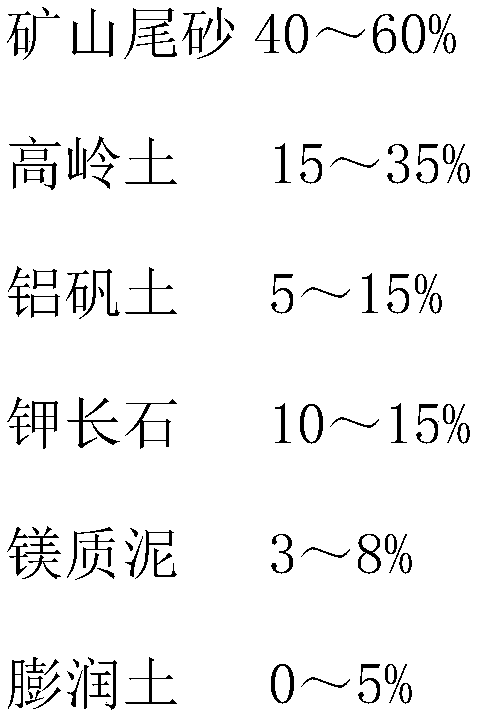

Mine tailing ceramic body and preparation method thereof

InactiveCN108046755APromote resource utilizationLarge particle sizeCeramic materials productionClaywaresSodium BentonitePotassium

The invention discloses a mine tailing ceramic body. The ceramic body comprises the following raw materials in percentage by mass: 40-60% of mine tailings, 15-35% of kaoline, 5-15% of bauxite, 10-15%of potassium feldspar, 3-8% of magnesia mud and 0-5% of bentonite. The ceramic body prepared by optimizing a formula and a preparation process has good physical property, has the water absorption rateof smaller than or equal to 0.5% and the bending strength of 35-45MPa and is capable of meeting the requirements of relevant product performances when being applied to production of building ceramics, sanitary ceramics and the like. Meanwhile, the invention discloses a preparation method of the mine tailing ceramic body. Mine tailings are recycled by using the method, so that natural resources are effectively saved, the comprehensive utilization of a mine tailing resource is promoted, and the natural resources are protected.

Owner:GUANGDONG BUILDING MATERIAL RES INST

High-dispersivity fluorescent whitening agent and preparation method thereof

ActiveCN101760048BImprove particle finenessGood dispersionStyryl dyesDetergent dyesInorganic saltsWhitening Agents

The invention provides a high-dispersivity fluorescent whitening agent, which comprises the following ingredients in percentage by weight: 20 to 45 parts of pure products converted from fluorescent whitening agent products represented by the following general formula or crude products with the fluorescent whitening agent, 2 to 30 parts of dispersing agents, 3 to 20 parts of inorganic salt and 2 to 10 parts of inorganic base. Water is added into the ingredients to be prepared into pulp with the solid content between 20 and 45 percent, the ingredients are ground into materials with the grain fineness smaller than or equal to 5 mm, and the grain type fluorescent whitening agent with the piling density larger than or equal to 450 kg*m<-3> is obtained through spraying drying. The high-dispersivity fluorescent whitening agent product prepared by the invention has the advantages of convenient use, long storage time, easy transportation and no dust pollution, and has high dispersivity in water, the dispersivity can be more than or equal to 50 percent in 2 min and can be more than 80 percent in 10 min, and the high-dispersivity fluorescent whitening agent can be widely used in washing industry. Formula is shown as the accompanying drawing.

Owner:山西晋光化工有限公司

Special water-soluble fertilizer for cucumbers and preparation method thereof

InactiveCN108863500AImprove nutrient activityReduce the difficulty of mixingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDissolution

The invention discloses a special water-soluble fertilizer for cucumbers and a preparation method thereof, and belongs to the technical field of a water-soluble fertilizer. The special water-soluble fertilizer is prepared from the following raw materials in parts by weight: 25 to 30 parts of urea, 15 to 25 parts of industrial monoammonium phosphate, 45 to 55 parts of potassium nitrate, 10 to 14 parts of calcium nitrate, 0.2 to 0.4 part of hydrochloric acid and 60 to 80 parts of deionized water. The method comprises the following steps of 1, heating deionized water to 95 to 98 DEG C; 2, addinghydrochloric acid according to the proportioning ratio; performing uniform stirring; 3, adding hydrochloric acid according to the proportioning ratio; performing uniform stirring; 3, adding industrialmonoammonium phosphate according to the proportioning ratio; performing stirring to complete dissolution; performing uniform mixing; 4, adding potassium nitrate and urea according to the mixture ratio; performing stirring to complete dissolution; performing uniform mixing; 5, slowly adding calcium nitrate into the materials according to the mixture ratio; after the addition is completed, performing uniform stirring; 6, after spray drying, performing cooling to obtain a finished product. The fertilizer has the advantages that the particle fineness is good; the water-soluble speed is high; thecucumber yield can be improved, and the like.

Owner:HUBEI FUSOURCE BIOLOGY OF BIOLOGICAL TECH CO LTD

Nanoscale antimony trioxide preparation device

InactiveCN104310473BHigh purityImprove particle finenessAntimony oxides/hydroxides/oxyacidsNanotechnologyEngineeringAir blower

Owner:GUANGXI GAOZHONG VALVE MFG

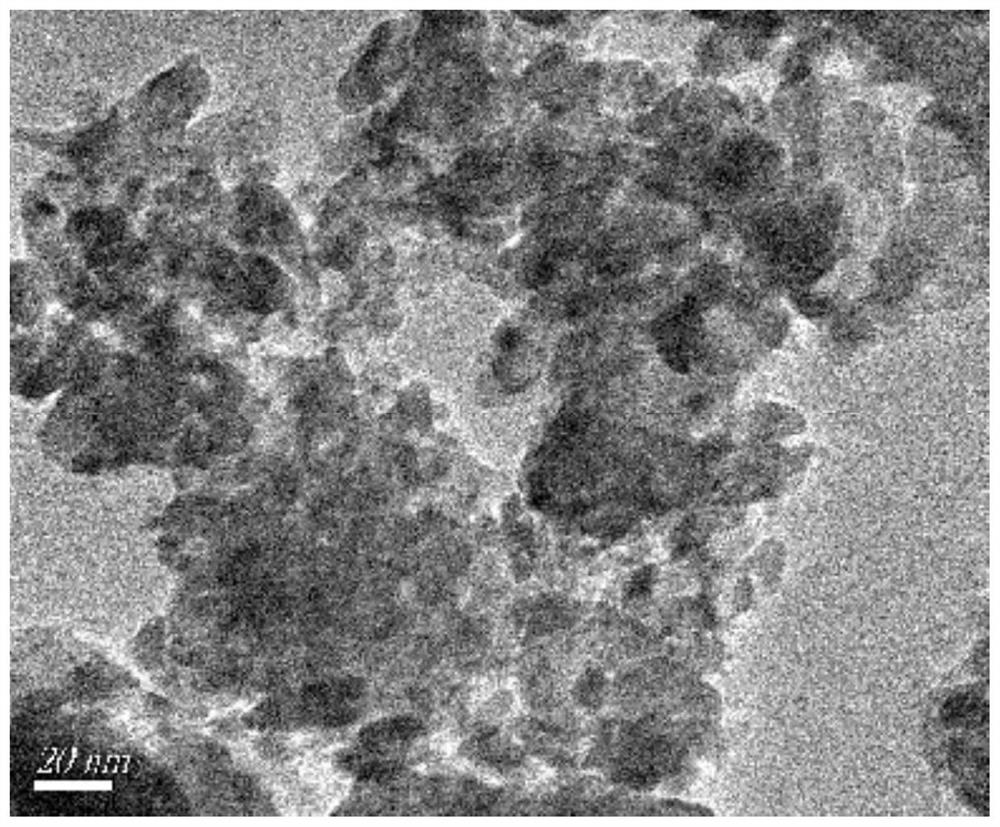

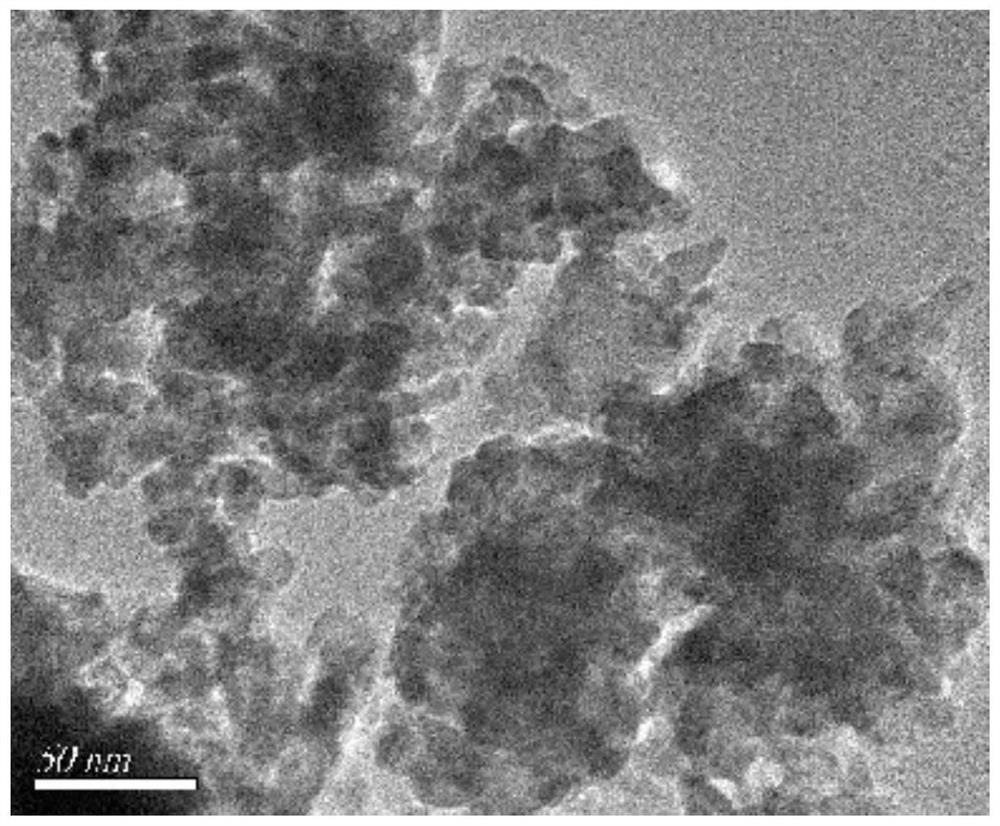

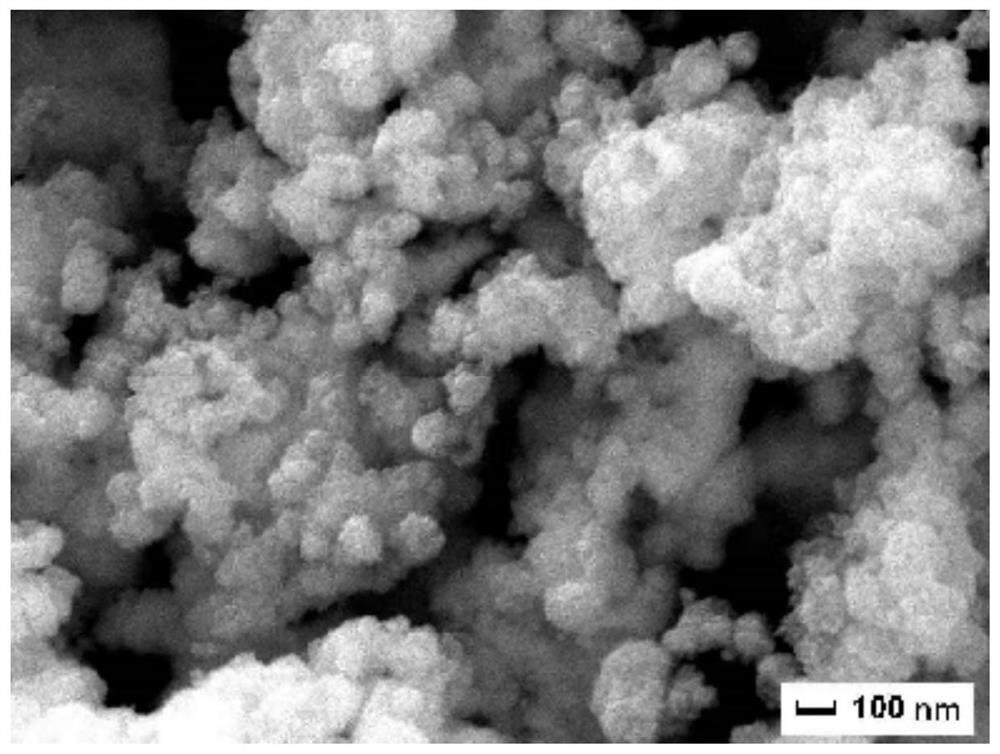

Preparation method for filling ultralow-resistivity conductive paste with high-purity nano material

PendingCN113618075AHigh puritySolve oxidationMaterial nanotechnologyInksConductive pastePhysical chemistry

The invention relates to a preparation method for filling ultralow-resistivity conductive paste with a high-purity nano-material. The preparation method comprises the following steps: preparing a nano-copper-based nano-material by using a chemical method, adding silver nitrate in the preparation process, and reducing silver oxalate generated by the silver nitrate into elemental Ag in a high-temperature state. On one hand, the elemental Ag has good conductivity as nano-copper, on the other hand, the elemental Ag has very strong oxidability, and the elemental Ag serving as an oxidant can significantly enhance the gas explosion effect of CO and CO2 in a roasting furnace, so that elemental copper generated along with the elemental Ag is cut into the nano-copper with finer and more uniform particles; and oxide generation is effectively avoided, the purity of the nano material is improved, and the resistivity is reduced. The resistivity of the prepared nano material is reduced to 26.9 microhm.cm from 12.6 milliohm.cm of an existing common material and is close to the theoretical resistivity 1.75 microhm.cm of copper, and the effect is remarkable.

Owner:孙珲

Method for preparing mashed purple sweet potato solid beverage

The invention discloses a method for preparing mashed purple sweet potato solid beverage. The method comprises the following steps of: pretreating purple sweet potatoes; cooking the pretreated purple sweet potatoes; preparing the cooked purple sweet potatoes into mashed potatoes; performing saccharification and glue milling on the mashed potatoes; and packaging to obtain a mashed purple sweet potato solid beverage product. In the method, the purple sweet potatoes are taken as a raw material and treated by a specific process so that the starch content of the raw material can be reduced, the soluble solid content, in particular the small-molecule sugar content of the raw material is increased, the solubility of the mashed purple sweet potatoes is enhanced and reconstitution performance is improved; and moreover, the method has the advantages of simple process flow, low requirement on equipment and capability of keeping constituents such as anthocyanin and the like of the purple sweet potatoes to the maximum extent, keeping the bright color of a prepared product and the inherent purple color of the raw material and making the product have high reconstitution performance and deliciousflavor.

Owner:XIHUA UNIV +2

A kind of preparation method of active dendrobium officinale superfine powder

ActiveCN104906384BStraight appearanceThe color is not destroyedPowder deliveryPlant ingredientsPolymer sciencePunching

The invention discloses a preparation method of active dendrobium candidum superfine powder, which comprises the following steps: 1) removing leaves from freshly harvested dendrobium candidum, washing and draining; 2) punching holes, fixing them on a mold, and placing them in a vacuum drying bin cooling on the shelf; the mold is a cube-shaped metal mold body (1) with semi-columnar grooves (2) on the upper surface, and small holes (3) are arranged on the mold body; 3) vacuuming; 4) Heating on the shelf, raising the temperature to 0°C, keeping the pressure at 20-100Pa, drying; raising the material from 0°C to 20°C, keeping the pressure at 10-20Pa, drying, raising the material from 20°C to 40°C, keeping the pressure within 10Pa , dried; raised to normal pressure; 5) low-temperature airflow pulverization to obtain more than 95% of the active dendrobium officinale superfine powder with a particle size of 20 μm or less. The invention has high freeze-drying rate, saves freeze-drying time, reduces energy consumption, has small particle size, is easy to dissolve and absorb, and has high bioavailability.

Owner:ZHEJIANG JIANFENG HEALTH TECH

Method for preparing nano-grade antimonous oxide

ActiveCN104326508AFully volatilePrevent volatilizationMaterial nanotechnologyAntimony compoundsAntimony trioxideAir blower

The invention discloses a method for preparing nano-grade antimonous oxide. The method comprises the following steps: 1, heating an antimony white furnace, and leading metallic antimony into a front hearth of the antimony white furnace for melting; 2, starting a rotating air blower on the top of the front hearth of the antimony white furnace so as to oxidize and volatilize antimony to form an antimonous oxide oxidization furnace gas; 3, blowing air to a top air blowing tube and a bottom air blowing tube at a middle hearth; 4, leading the antimonous oxide oxidization furnace gas into a reaction chamber for reaction; and 5, leading the antimonous oxide oxidization furnace gas into a double-layer crystallizer, passing through a natural air cooling and annular cooling pipeline, cooling, crystallizing on a crystallization baffle, and collecting by using a cloth bag dust collector, thereby obtaining antimonous oxide.

Owner:SHANTOU SHUANGPENG PLASTIC IND

A compound wet-grinding concrete waste slag functional additive and its application

The invention discloses a compound type wet-grinding concrete waste slag functional additive and its application. The components and mass parts are: 140-160 parts of grinding aid component, 140-160 parts of dispersing component, and retarding component 60-80 parts, early strength component 10-20 parts, water 160-180 parts. This functional additive is specially designed for concrete waste residue. It has multiple functions such as grinding aid, dispersion, slump retention (retarding) and early strength. It is liquid at room temperature, low in dosage and environmentally friendly. When used for wet grinding of concrete waste, it can effectively improve the efficiency of wet grinding. The obtained waste slurry is uniformly dispersed and stable with extremely high particle fineness. It has high activity and is easy to store and transport. Effectively improve the early strength and work performance of concrete, and have high engineering application value.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

A kind of water-soluble fertilizer containing middle element to promote fruit expansion and preparation method thereof

The invention discloses a secondary element containing water soluble fertilizer for promoting fruit expansion and a preparation method of the water soluble fertilizer and belongs to the technical field of water soluble fertilizers. The water soluble fertilizer is prepared from raw materials in parts by weight as follows: 15-30 parts of urea, 6-20 parts of industrial monoammonium phosphate, 30-90 parts of potassium nitrate, 3-10 parts of calcium nitrate, 0.1-1 part of hydrochloric acid and 30-60 parts of deionized water. The preparation method comprises steps as follows: 1, the deionized water is heated to 95-98 DEG C; 2, hydrochloric acid is added in parts by weight, and the mixture is uniformly stirred; 3, the industrial monoammonium phosphate is added in proportion and stirred until the industrial monoammonium phosphate is completely dissolved, and the mixture is uniformly mixed; 4, potassium nitrate and urea are added in proportion and stirred until potassium nitrate and urea are completely dissolved, and the mixture is uniformly mixed; 5, calcium nitrate is added slowly in batches in proportion, and then, the mixture is uniformly stirred; 6, after spray drying, the mixture is cooled, and a finished product is obtained. The fertilizer has the advantages of good grain fineness, high water dissolving speed, high fertilizer nutrient activity and the like.

Owner:HUBEI XIANGYUN GROUP CHEM

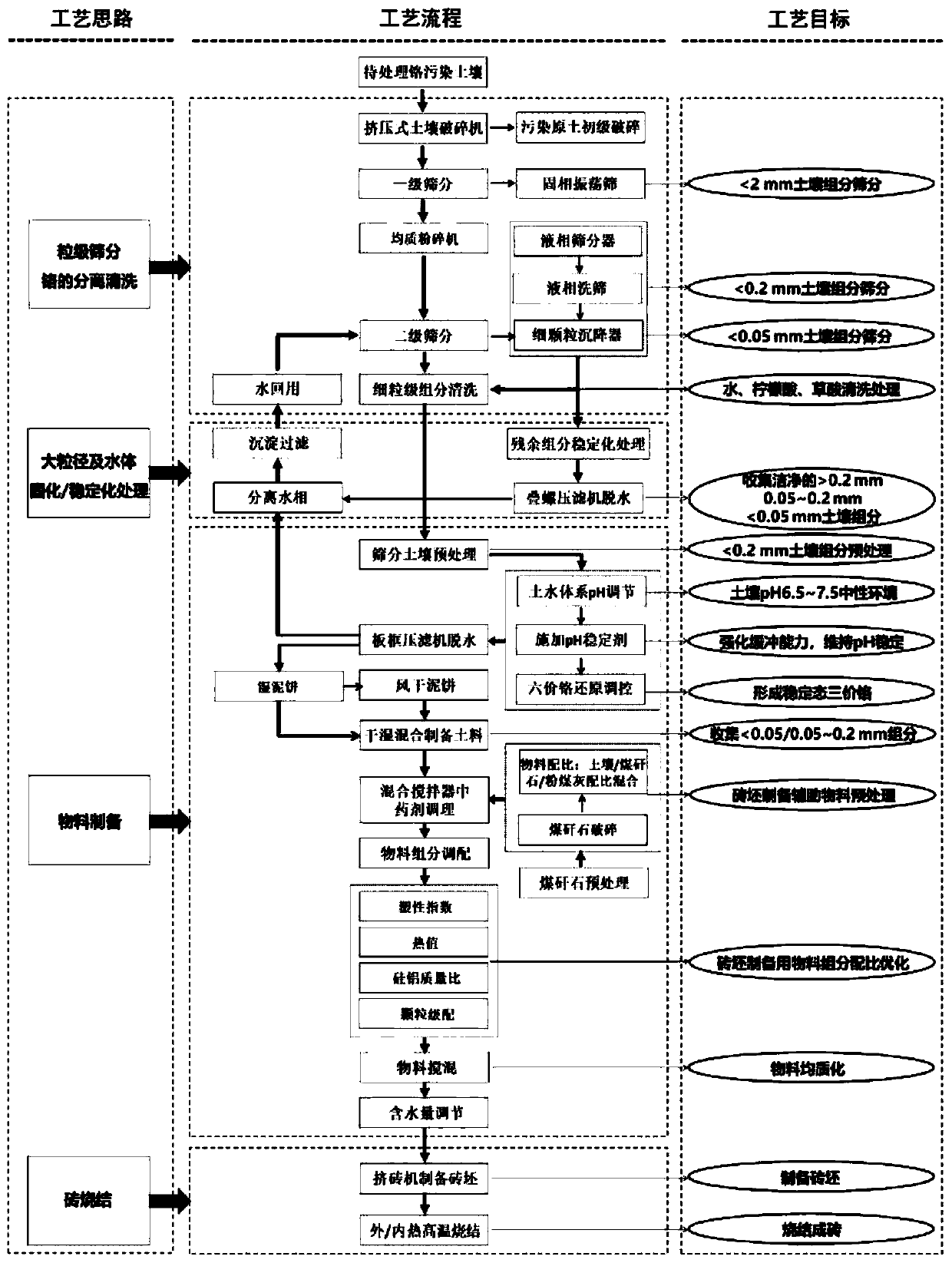

A harmless and resourceful restoration method for chromium-contaminated soil

ActiveCN108746187BBoth resource utilizationGreat economic advantageWater contaminantsContaminated soil reclamationBrickMixed materials

The invention relates to a heavy-metal-contaminated soil remediation technology, in particular to a harmless and recycling remediation method for chromium-contaminated soil. The to-be-treated chromium-contaminated soil is subjected to particle-grade component screening through a two-stage screening method and cleaned, and fine sand particle components of 0.05-0.2 mm and powder particle / clay particle components of smaller than 0.05 mm are obtained; the soil components of 0.05-0.2 mm and smaller than 0.05 mm are treated through soil pH adjusting, pH stability strengthening and hexavalent chromium (Cr(VI)) reduction; then according to the mixed material parameter optimization requirements (the plastic index, the calorific value, the silicon aluminum mass ratio and the particle grade), the contaminated soil of the fine sand particle components, the contaminated soil of the powder particle / clay particle components, coal gangue and fly ash with the established weight ratio are matched and mixed, and the mixed material is fully stirred and homogenized; and the mixed material is subjected to green brick pressing after water content adjusting and sintered into a brick in the mode that hightemperature sintering is combined with brick body internal combustion, and thus harmless and recycling remediation for the contaminated soil sintered brick is achieved. The harmless and recycling remediation method has the characteristics of heavy-metal-chromium-contaminated soil remediation and recycling utilization, and has large economic advantages and industrialization prospects compared withother heavy-metal-contaminated soil remediation technologies.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

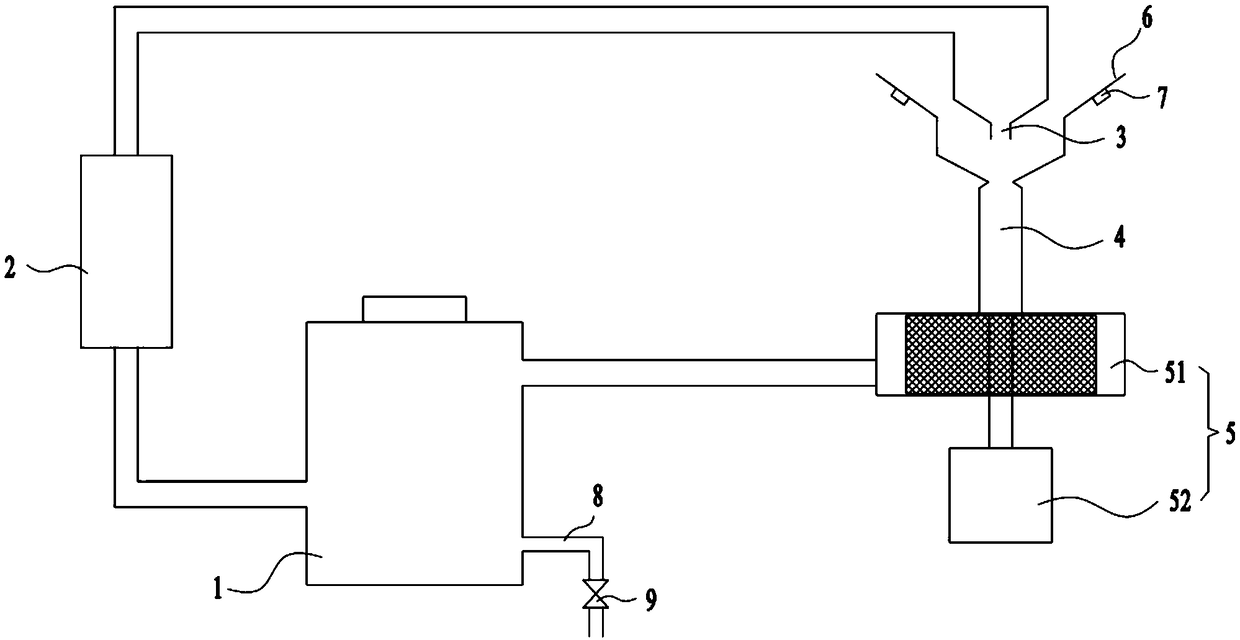

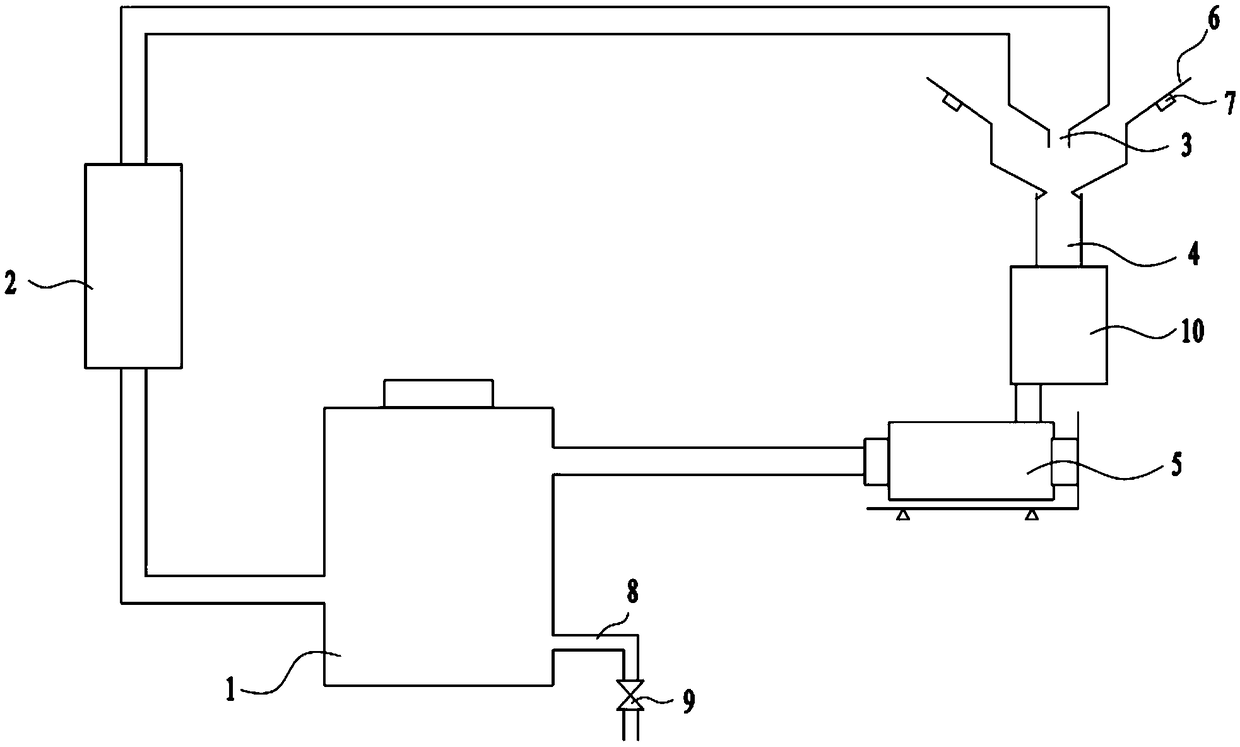

Solid-liquid mixing equipment and method

InactiveCN109304109AEnhanced mixing processIncrease the areaFlow mixersTransportation and packagingSpray nozzleEngineering

The invention discloses solid-liquid mixing equipment. The solid-liquid mixing equipment comprises a storage tank, a first pump body, a nozzle, a material receiving pipe, a second pump body, a sand mill,wherein a feed port of the first pump body is connected to the storage tank, the tail part of the nozzle is connected to a discharge port of the first pump body, one end of the material receiving pipe is located in the material liquid spraying direction of the nozzle, a feed port of the second pump body is connected to the other end of the material receiving pipe, a feed port of the sand mill is connected to a discharge port of the second pump body and is connected to the other end of the material receiving pipe, and a discharge port of the sand mill is connected to the storage tank. The invention further discloses a solid-liquid mixing method based on the solid-liquid mixing equipment. According to the solid-liquid mixing equipment, the storage tank is separated from the sand mill, a solid-liquid mixture can be uniformly treated, so that the mixing time of feed liquid is prolonged, and therefore the mixing degree is more uniform; and the nozzle is arranged, so that ejected fluid can enter the material receiving pipe quickly, so that negative pressure is formed at the periphery of a pipe orifice of the material receiving pipe, and the materials can be sucked into the material receiving pipe.

Owner:哈尔滨万鑫石墨谷科技有限公司

Mountain ant capsule and preparation process thereof

InactiveCN108042629AHigh availability of medicinal ingredientsImprove utilizationNervous disorderAnthropod material medical ingredientsSporeNotopterygium incisum

The invention provides a mountain ant capsule and a preparation process thereof. The capsule comprises a core material and a capsule material, wherein the core material consists of 10 to 25 weight percent of a medicinal component and 75 to 90 weight percent of auxiliary materials; the medicinal component comprises a mountain ant powder, a ginger powder, an acanthopanax fruit powder, a ganoderma spore powder, Chinese angelica, gentian macrophylla, notopterygium incisum, erythrina indica lam and sanguisorba officinalis; and the auxiliary material comprises a diluent, a lubricating agent, a disintegrating agent, a wetting agent, an antioxidant and an adsorbent. The mountain ant capsule, which is prepared through reasonable optimal selection of the raw materials, has high utilization degree ofmedicinal components and high release continuity of effective components, has an excellent effects of whitening skin and beautifying skin, strengthening body and calming nerves, dispelling wind and eliminating dampness as well as easing pain and caring health, and is worthy of market popularization.

Owner:吉林省山健生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com