Regenerated UHPC cement concrete and preparation method thereof

A technology for cement concrete and recycled cement, applied in the field of green building materials, can solve the problems of low cement content and worrying promotion prospects, and achieve the effects of increasing particle fineness, being beneficial to environmental protection, and reducing process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

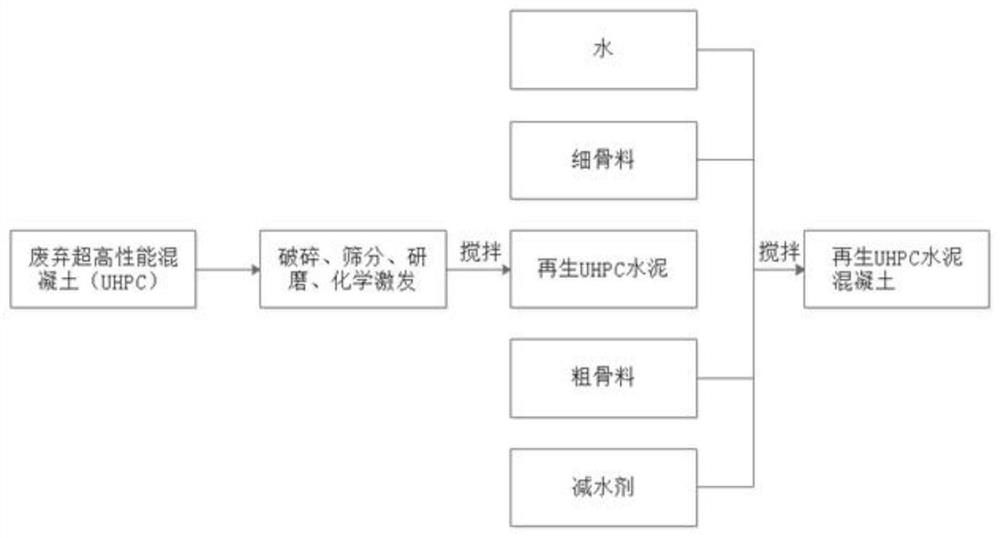

[0026] A preparation method for recycled UHPC cement concrete, comprising the following steps:

[0027] S1, crushing, sieving and grinding the waste UHPC to obtain d 90 Regenerated UHPC micropowder S2 smaller than 75 μm, adding 1% Ca(OH) to the regenerated UHPC micropowder obtained in step S1 2 The activator is stirred and mixed evenly, so as to prepare the recycled UHPC cement.

[0028] S3. Weigh each raw material according to the following parts by weight, 300kg of recycled UHPC cement, 120kg of water, 620kg of river sand, 1030kg of gravel, and 2.0kg of high-efficiency polycarboxylate superplasticizer;

[0029] S4. Pour gravel, recycled UHPC cement, and river sand into the mixer in sequence, and stir for 30s

[0030] S5. Then mix water and high-efficiency polycarboxylate superplasticizer, pour it into a blender, stir and cure.

Embodiment 2

[0032] A preparation method containing recycled UHPC cement concrete, comprising the following steps:

[0033] S1, crushing, sieving and grinding the waste UHPC to obtain d 90 Regenerated UHPC micropowder less than 75μm.

[0034] S2, the UHPC regenerated micropowder that S1 step obtains is added the Na that quality is 2% 2 SiO 4 The activator is stirred and mixed evenly, so as to prepare the recycled UHPC cement.

[0035] S3. Weigh each raw material according to the following parts by weight, 300kg of recycled UHPC cement, 105kg of water, 580kg of recycled UHPC fine aggregate, 1000kg of gravel, and 2.0kg of high-efficiency polycarboxylate superplasticizer;

[0036] S4. Pour the recycled UHPC fine aggregate, gravel, and recycled UHPC cement into the mixer in order, and stir for 30s

[0037] S5. Then mix water and high-efficiency polycarboxylate superplasticizer, pour it into a blender, stir and cure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com