Mine tailing ceramic body and preparation method thereof

A ceramic body and tailings technology, which is applied in the field of mine tailings ceramic body and its preparation, can solve the problems of unstable quality of mine tailings, low sintering efficiency, and pollution of human living environment, so as to improve sintering efficiency and mechanical strength. performance, promoting the comprehensive utilization of resources, and the effect of saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

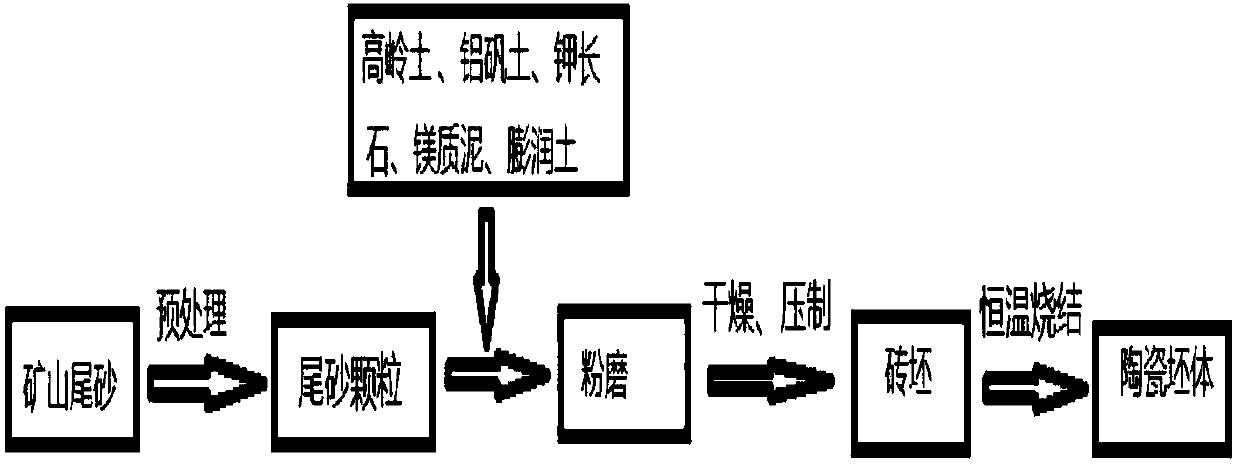

Method used

Image

Examples

Embodiment 1

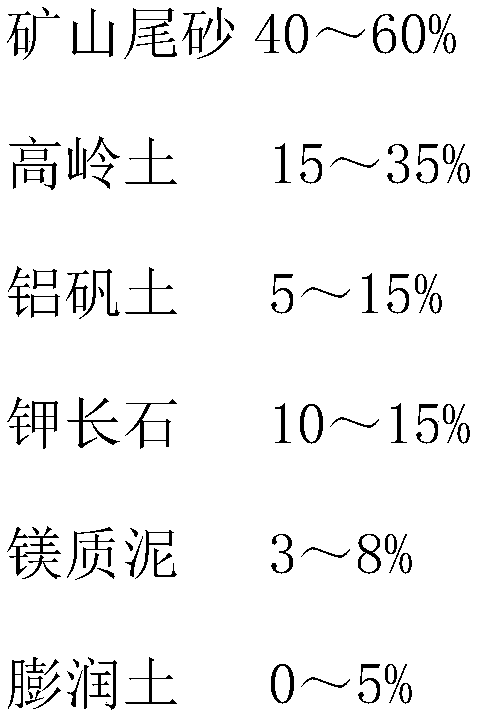

[0033] A mine tailings ceramic green body, the green body blank includes the following raw materials in mass percentage: 50% of mine tailings, 20% of kaolin, 10% of bauxite, 15% of potassium feldspar, and 5% of magnesia mud.

[0034] The mine tailings in the mine tailings green body blank mainly include tin tailings and gold tailings. After chemical analysis, the SiO in the tin tailings 2 The content is 76.8%, Al 2 o 3 Content is 13.5%, gold tailings SiO 2 The content is 83.6%, Al 2 o 3 The content is 10.9%.

[0035] In this embodiment, the mass ratio of tin tailings and gold tailings is 1.0.

[0036] In this embodiment, the specific preparation method includes the following steps:

[0037] (1) Mine tailings are pretreated by drying, magnetic separation and iron removal, and preliminary crushing and screening to obtain tailings with a particle size of ≤0.15mm and an Fe element content of ≤1.0%;

[0038] (2) The pretreated mine tailings, kaolin, bauxite, potassium feldsp...

Embodiment 2

[0043] A mine tailings ceramic green body, the green body blank includes the following raw materials in mass percentage: 55% of mine tailings, 20% of kaolin, 2% of bentonite, 8% of bauxite, 10% of potassium feldspar, magnesia mud 5%.

[0044] The mine tailings in the mine tailings green body blank mainly include tin tailings and gold tailings. After chemical analysis, the SiO in the tin tailings 2 The content is 76.8%, Al 2 o 3 Content is 13.5%, gold tailings SiO 2 The content is 83.6%, Al 2 o 3 The content is 10.9%.

[0045] In this embodiment, the mass ratio of tin tailings and gold tailings is 1.5.

[0046] In this embodiment, the method for preparing the mine tailings ceramic body includes the following steps:

[0047] (1) Mine tailings are pretreated by drying, magnetic separation and iron removal, and preliminary crushing and screening to obtain tailings with a particle size of ≤0.15mm and an Fe element content of ≤1.0%;

[0048] (2) The pretreated mine tailings,...

Embodiment 3

[0053] A mine tailings ceramic green body, the green body blank includes the following raw materials in mass percentage: 45% of mine tailings, 25% of kaolin, 5% of bentonite, 10% of bauxite, 11% of potassium feldspar, magnesia Mud 4%.

[0054] The mine tailings in the mine tailings green body blank mainly include tin tailings and gold tailings. After chemical analysis, the SiO in the tin tailings 2 The content is 76.8%, Al 2 o 3 Content is 13.5%, gold tailings SiO 2 The content is 83.6%, Al 2 o 3 The content is 10.9%.

[0055] In this embodiment, the mass ratio of tin tailings and gold tailings is 1.2.

[0056] In this embodiment, the specific preparation method includes the following steps:

[0057] (1) Mine tailings are pretreated by drying, magnetic separation and iron removal, and preliminary crushing and screening to obtain tailings with a particle size of ≤0.15mm and an Fe element content of ≤1.0%;

[0058] (2) The pretreated mine tailings, kaolin, bauxite, potas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com