Processing method of ready-to-eat oat and surimi crispy chips

A processing method and surimi technology are applied to the processing field of instant oat surimi chips, which can solve the problems of poor solubility and easy agglomeration, and achieve the effects of avoiding easy agglomeration, fast heating and simple operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

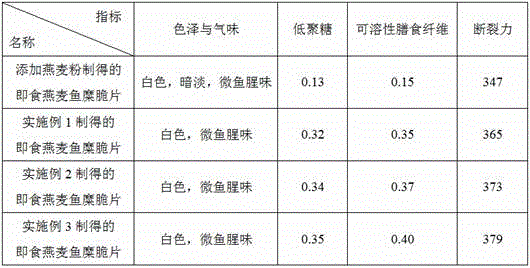

Examples

Embodiment 1

[0029] A processing method of instant oatmeal surimi chips, the steps are as follows:

[0030] 1) Oat crushing: crush the oats and pass through an 80-mesh sieve to obtain oat flour;

[0031] 2) Preparation of oat pulp by high-pressure homogenization: add water to oat flour at a weight-to-volume ratio of 2:1 (g / mL), and homogenize for 8 minutes under a pressure of 20 MPa to form oat pulp;

[0032] 3) Cutting and mixing: including empty chopping, salt chopping, and mixed chopping, that is, put the half-thawed surimi into a high-speed chopping machine, and chop it empty for 3 minutes; add salt with 2% of the weight of the surimi, and chop it with salt for 5 minutes to make the fish meat The salt-soluble protein in the water is fully dissolved; continue to chop and mix, and add 5% starch by weight of surimi, 5% soybean protein isolate, 3% white sugar, 0.2% monosodium glutamate, 10% oat pulp, and then add Egg white powder with 5% weight of surimi was chopped and mixed for 8 minute...

Embodiment 2

[0036] A processing method of instant oatmeal surimi chips, the steps are as follows:

[0037] 1) Oat crushing: crush the oats and pass through an 80-mesh sieve to obtain oat flour;

[0038] 2) Preparation of oat pulp by high-pressure homogenization: add water to oat flour at a weight-to-volume ratio of 2:1 (g / mL), and homogenize under a pressure of 30 MPa for 5 minutes to form oat pulp;

[0039] 3) Cutting and mixing: including empty chopping, salt chopping, and mixed chopping, that is, put the half-thawed surimi into a high-speed chopping machine, and chop it empty for 3 minutes; add salt with 2% of the weight of the surimi, and chop it with salt for 5 minutes to make the fish meat The salt-soluble protein in the water is fully dissolved; continue to chop and mix, and add 8% starch by weight of surimi, 6% soybean protein isolate, 4% white sugar, 0.2% monosodium glutamate, 12% oat pulp, and then add Egg white powder with 8% weight of surimi was chopped and mixed for 8 minute...

Embodiment 3

[0043] A processing method of instant oatmeal surimi chips, the steps are as follows:

[0044]1) Oat crushing: crush the oats and pass through an 80-mesh sieve to obtain oat flour;

[0045] 2) Preparation of oat pulp by high-pressure homogenization: add water to oat flour at a weight-to-volume ratio of 2:1 (g / mL), and homogenize for 6 minutes under a pressure of 25 MPa to form oat pulp;

[0046] 3) Cutting and mixing: including empty chopping, salt chopping, and mixed chopping, that is, put the half-thawed surimi into a high-speed chopping machine, and chop it for 3 minutes; The salt-soluble protein in the water is fully dissolved; continue to chop and mix, and add 10% starch by weight of surimi, 7% soybean protein isolate, 5% white sugar, 0.3% monosodium glutamate, 15% oat milk, and then add Egg white powder with 10% weight of surimi was chopped and mixed for 8 minutes. During the mixing, ice water with 35% weight of surimi was added in 3 times to control the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com