Device for preparing nanoscale antimony trioxide

A technology for preparing antimony trioxide and equipment, which is applied in the direction of nanotechnology, antimony oxide/antimony hydroxide/antimony oxyacid, inorganic chemistry, etc., and can solve the needs of the purity of antimony trioxide and market progress, etc. problems, to achieve the effect of simple structure, high particle fineness and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

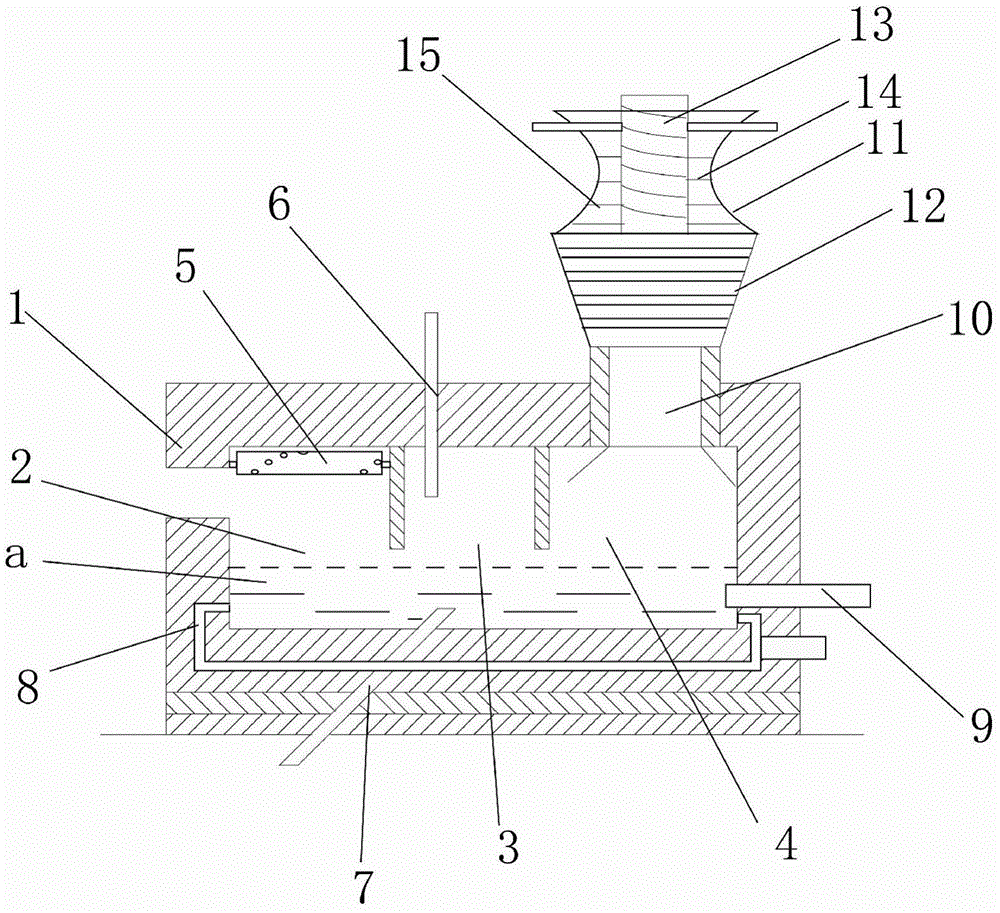

[0028] like Figure 1-2 As shown, the nanoscale antimony trioxide preparation device of the invention includes an antimony white furnace 1 and a crystallizer 11. The antimony white furnace 1 is provided with a connected front chamber 2, middle chamber 3 and breech chamber 4, and the top position of the front chamber 2 is , the upper position of the metal antimony liquid a is provided with a rotary blower 5, and the rotary blower 5 is installed on the top of the front chamber 2 through a rotating part, such as a rotating rod. On the outer surface of the blower, its wind source and power come from the exhaust fan (not shown in the figure).

[0029] Bottom blowpipe 7 and top blowpipe 6 are arranged at middle chamber 3, and bottom blowpipe 6 extends into metal antimony liquid a, and top blowpipe 6 passes antimony white furnace 1 and extends into the surface of metal antimony liquid a,

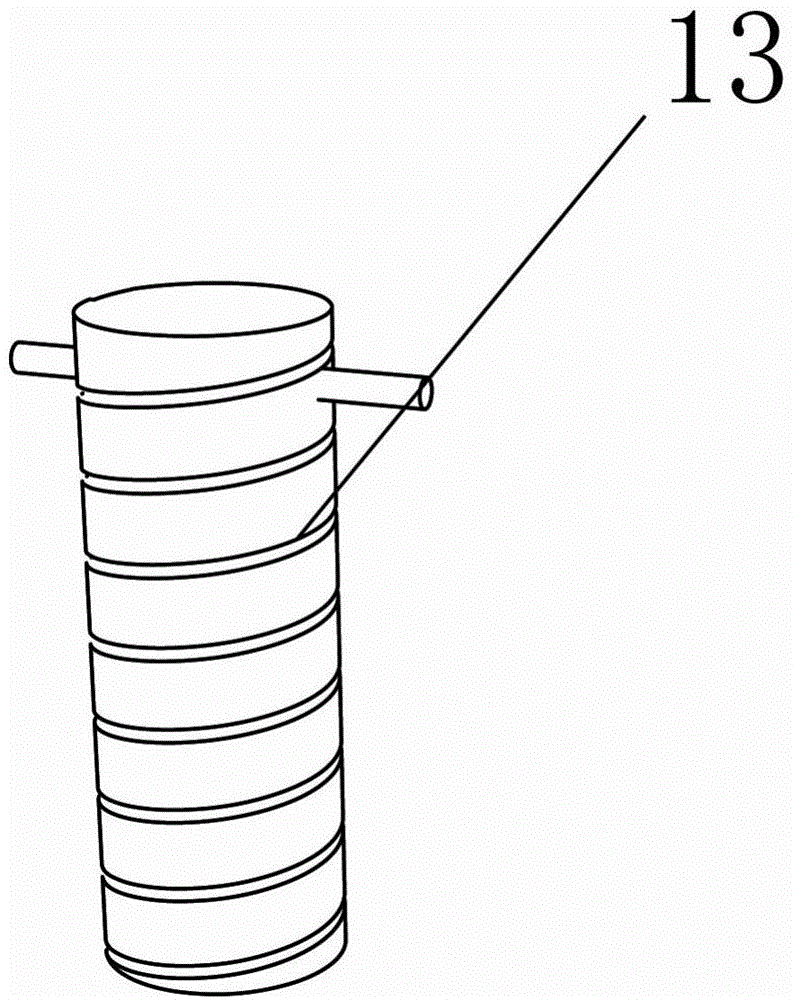

[0030] A reactor 10 is connected to the top of the breech 4 , and a crystallizer 11 is arrange...

Embodiment 2

[0034] In the present embodiment, the blast volume 5 of the rotary blower is 210 3 / h, the blowing volume of the blowing pipe 7 at the bottom is 0.5MPa, and the flow rate is 260m 3 / h, all the other working principles are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com