Preparation method for active dendrobium candidum superfine powder

A technology of dendrobium candidum and superfine powder, which is applied in the direction of medical preparations containing active ingredients, powder delivery, pharmaceutical formulas, etc., can solve the problems of high energy consumption, long production cycle, and high operating cost, and achieve small contact area and short production cycle. Excellent effect of shortening and rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of active dendrobium officinale superfine powder is characterized in that it comprises the steps:

[0027] 1) Remove the leaves from the freshly harvested Dendrobium officinale, wash and drain;

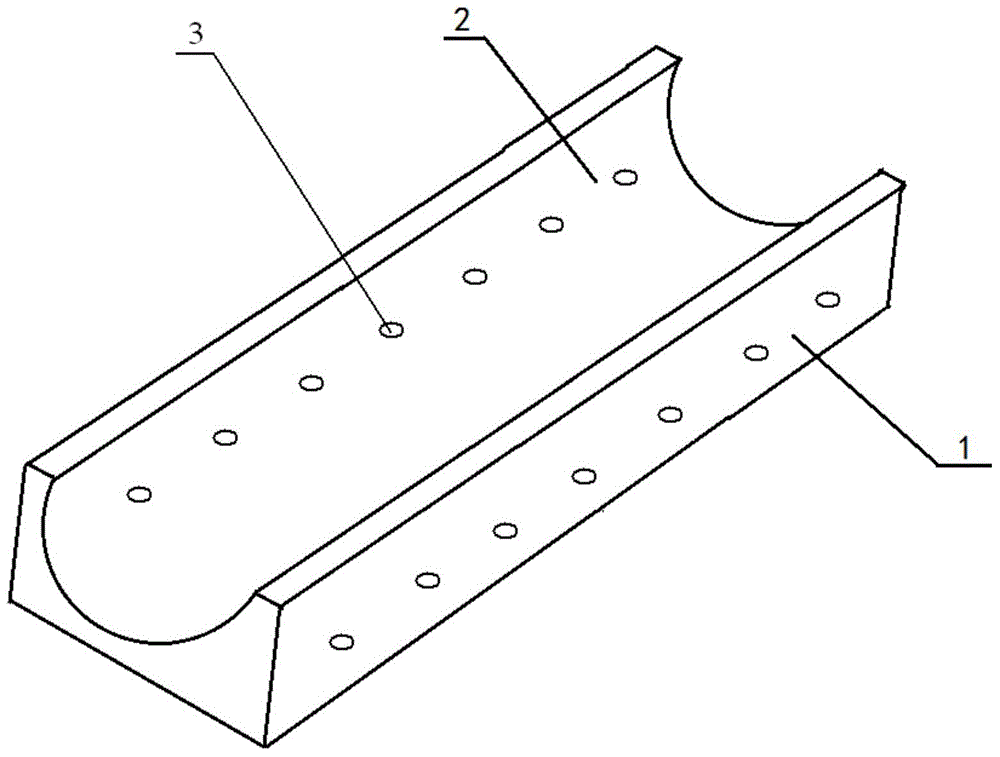

[0028] 2) Perforate the Dendrobium candidum obtained in step (1), fix the perforated Dendrobium candidum on the mold, place it in a vacuum drying bin, cool the material to -35°C to -40°C, and keep it for 2 hours; The mold is a cubic metal mold body (1) with semi-columnar grooves (2) on the upper surface, and small holes (3) are arranged on the mold body; the metal is stainless steel.

[0029] 3) Vacuum until the pressure is 20-100Pa, and maintain for 2 hours;

[0030] 4) Heat the shelf in the vacuum drying chamber to raise the material from -35°C to -40°C to 0°C, keep the pressure at 20-100Pa, and sublimate and dry for 15 hours; Keep it at 10-20Pa, analyze and dry for 2 hours, raise the material from 20°C to 40°C, keep the pressure within 10Pa, analyze an...

Embodiment 2

[0034] A preparation method of active dendrobium officinale superfine powder is characterized in that it comprises the steps:

[0035] 1) Remove the leaves from the freshly harvested Dendrobium candidum, wash, drain, and cut into 10cm sections;

[0036] 2) Perforate the Dendrobium candidum obtained in step (1), fix the perforated Dendrobium candidum on the mold, place it in a vacuum drying bin, cool the material to -35°C to -40°C, and keep it for 3 hours; The mold is a cubic metal mold body (1) with semi-columnar grooves (2) on the upper surface, and small holes (3) are arranged on the mold body; the metal is copper.

[0037] 3) Vacuum until the pressure is 20-100Pa, and maintain for 3 hours;

[0038] 4) Heat the shelf in the vacuum drying chamber to raise the material from -35°C to -40°C to 0°C, keep the pressure at 20-100Pa, and sublimate and dry for 10 hours; Keep it at 10-20Pa, analyze and dry for 3 hours, raise the pressure of the material from 20°C to 40°C, keep it wit...

Embodiment 3

[0042] A preparation method of active dendrobium officinale superfine powder is characterized in that it comprises the steps:

[0043] 1) Remove the leaves from the freshly harvested Dendrobium candidum, wash, drain, and cut into 1cm sections;

[0044] 2) Perforate the Dendrobium candidum obtained in step (1), fix the perforated Dendrobium candidum on the mold, place it in a vacuum drying bin, cool the material to -35°C to -40°C, and keep it for 1 hour; The mold is a cubic metal mold body (1) with semi-columnar grooves (2) on the upper surface, and small holes (3) are arranged on the mold body; the metal is stainless steel;

[0045] 3) Vacuum until the pressure is 20-100Pa, and maintain for 1 hour;

[0046] 4) Heat the shelf in the vacuum drying chamber to raise the material from -35°C to -40°C to 0°C, keep the pressure at 20-100Pa, and sublimate and dry for 20 hours; Keep it at 10-20Pa, analyze and dry for 1 hour, raise the pressure of the material from 20°C to 40°C, keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com