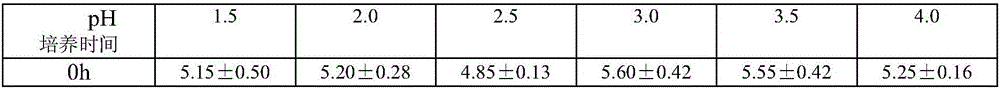

Patents

Literature

228results about How to "Shorten freeze-drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel micro powder and preparation method thereof

InactiveCN108689412AImprove drying efficiencyShorten freeze-drying timeChemical industryFerric oxidesPorosityOrganic solvent

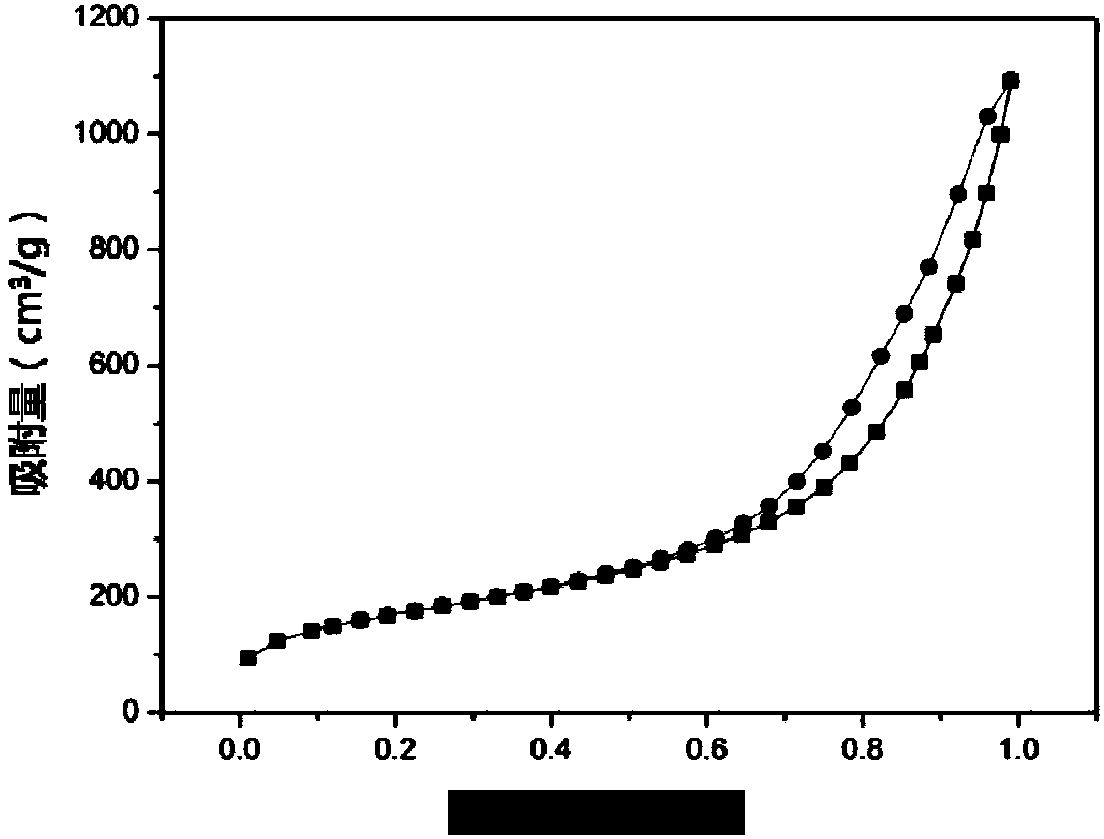

The invention discloses aerogel micro powder and a preparation method thereof. The method comprises the following steps: a hydrogel is provided, and fragmentation is carried out on the hydrogel and dispersing the hydrogel to obtain gel fluid or gel dispersion liquid; an atomizing device is employed for performing atomization on the gel fluid or the gel dispersion liquid, gel droplets are formed, the gel droplets are collected by a low-temperature container, and the gel freezing particles are obtained; the freeze drying is carried out, and the aerogel micro powder is obtained. The aerogel micropowder can realize integration of granulation and refrigeration, pre-refrigeration is not required, rapid and continuous production of the aerogel micro powder can be realized, organic solvent displacement is not required, the preparation method has the advantages of simple process, short production period, low cost, energy saving, and environmental protection, the preparation process can be amplified to industrial production, and the obtained aerogel micro powder has the excellent physical properties of controllable morphology, uniform particle size, large specific surface area, high porosity amount, and low thermal conductivity.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

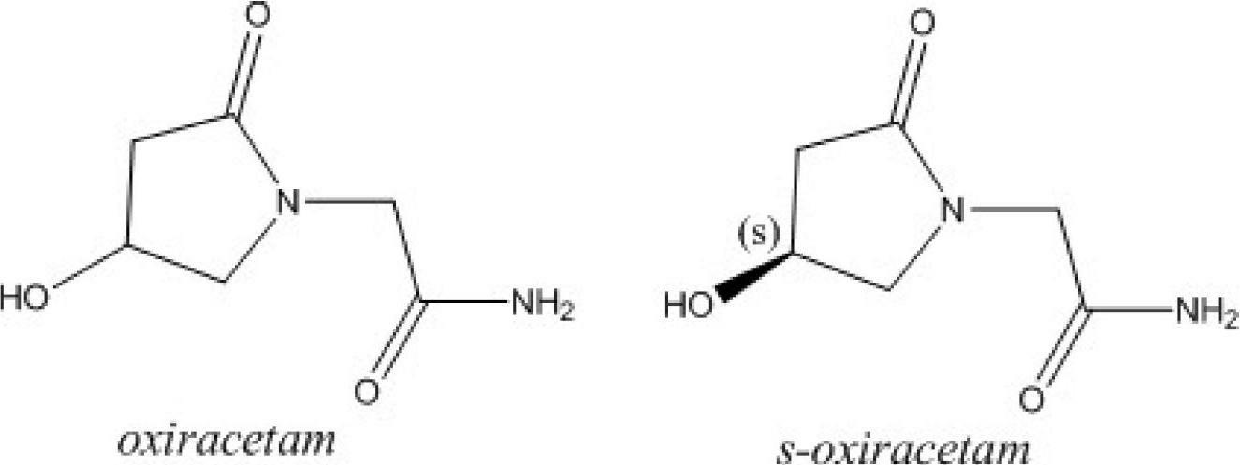

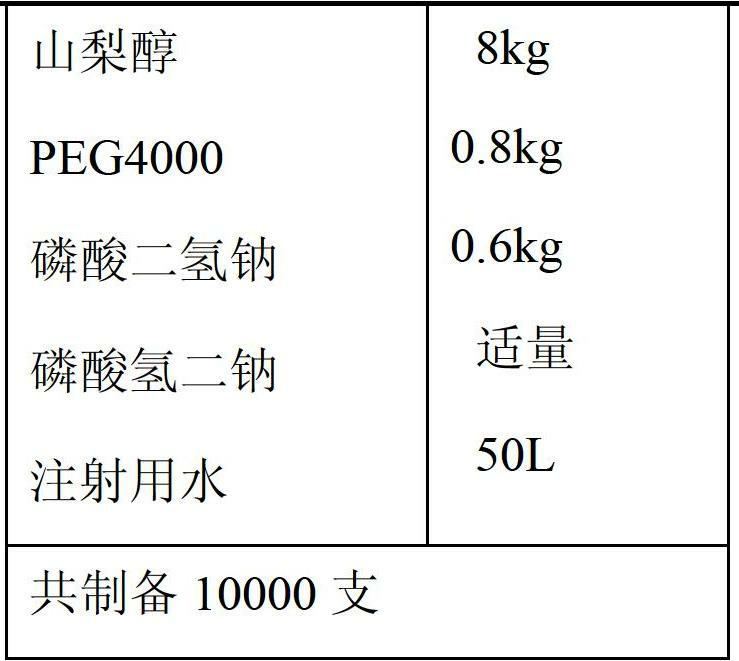

Freeze-dried powder injection of L-oxiracetam and process for preparing freeze-dried powder injection

ActiveCN102670527AFast sublimationShorten freeze-drying timePowder deliveryOrganic active ingredientsPolyethylene glycolEngineering

The invention relates to a freeze-dried powder injection of L-oxiracetam and a process for preparing the freeze-dried powder injection. The freeze-dried powder injection comprises, by weight, 1 part of the L-oxiracetam, 0.1 to 10 parts of an excipient, 0.01 to 1 part of an antisticking agent and 0.01 to 0.5 part of a pH regulator, wherein polyethylene glycol (PEG) series of products serve as the antisticking agent preferably. The freeze-dried powder injection which is prepared on the basis of a prescription according to the process has the advantages of being short in freeze-drying time, attractive in appearance, short in redissolving time and high in stability.

Owner:南京博德生物制药有限公司

Method for preparing fresh grosvener siraitia freeze-dried superfine powder

InactiveCN101720894AIncrease profitPreserve active ingredientsFood shapingFood preparationFreeze-dryingPre treatment

The invention discloses a method for preparing fresh grosvener siraitia freeze-dried superfine powder, relates to processing technology for fruits and vegetables, and provides a method for preparing fresh grosvener siraitia freeze-dried superfine powder, which combines vacuum freeze drying technology with superfine grinding technology to protect effective components of the grosvener siraitia and realize full utilization of the grosvener siraitia. The method comprises the following steps: carrying out pretreatments such as selecting, cleaning, sterilization and the like on the fresh grosvener siraitia; putting the grosvener siraitia on a tray for prefreezing after crushing; putting the prefreezed grosvener siraitia in a vacuum environment for heating and drying at the temperature of between 40 and 120 DEG C; controlling the moisture content of the freeze-dried product to less than 6 percent; and finally, grinding the dried grosvener siraitia until the particle size of the powder reaches 10 to 40 meshes, and then carrying out superfine grinding on the powder by a superfine grinding machine until the particle size of the powder reaches less than 40 microns. Because the product is superfine powder, thus, the fresh grosvener siraitia freeze-dried superfine powder has the advantages of small powder particle, big surface area, delicate taste, quicker absorption and wider application, the superfine powder can be eaten directly, and can also be used as the raw materials of other foods, health-care products, medicaments and cosmetics.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Method for quickly preparing non-puffing low sugar fruit freeze-dry crisp pieces

ActiveCN101433300AShorten freeze-drying timeLow costFruits/vegetable preservation by freezing/coolingFood preparationFreeze-dryingVacuum drying

The invention discloses a method for quickly preparing non-puffed low-sugar fruit jelly crispy chips and belongs to the technical field of fruit and vegetable food processing. Fruit chips are mainly prepared by the following steps: fruit washing, peeling, pit removal, slicing, pretreatment, freezing, freezing and drying, microwave vacuum drying, hot air drying and packaging. The method adopts freezing and drying in a sublimation drying stage of the fruit chips and controls the water content of products to be 37 percent. The method adopts microwave vacuum drying till the water content of the fruit chips is 10 percent in a resolving drying stage, and then adopts hot air dying to make the terminal water content of the fruit chips less than 5 percent. Low-sugar fruits are apples, pears or peaches which have a sugar degree of between 8 and 10. As post treatment of the freezing and drying, microwave vacuum drying and hot air drying greatly reduce energy consumption. Meanwhile, compared with lyophilized products, products dried by the method have no obvious change in quality and appearance.

Owner:SHANDONG LUHUA GROUP +1

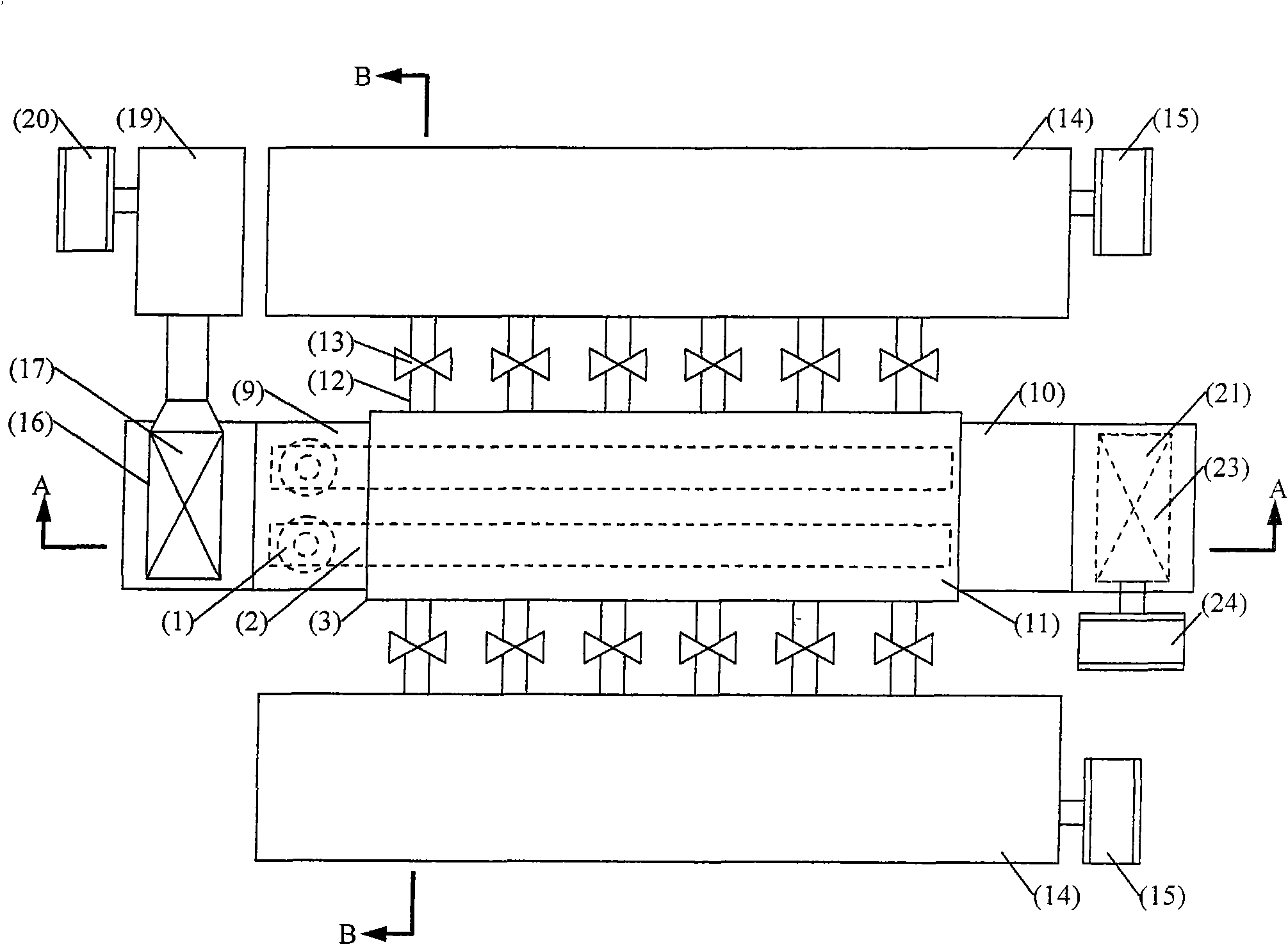

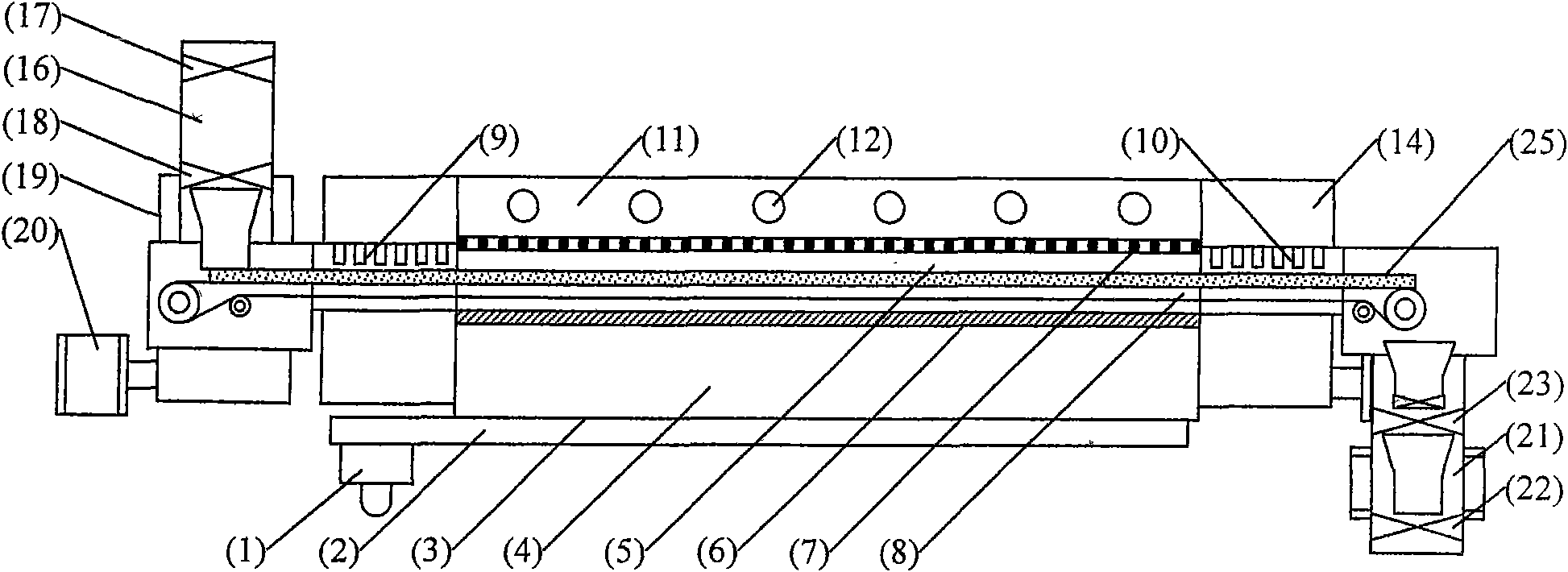

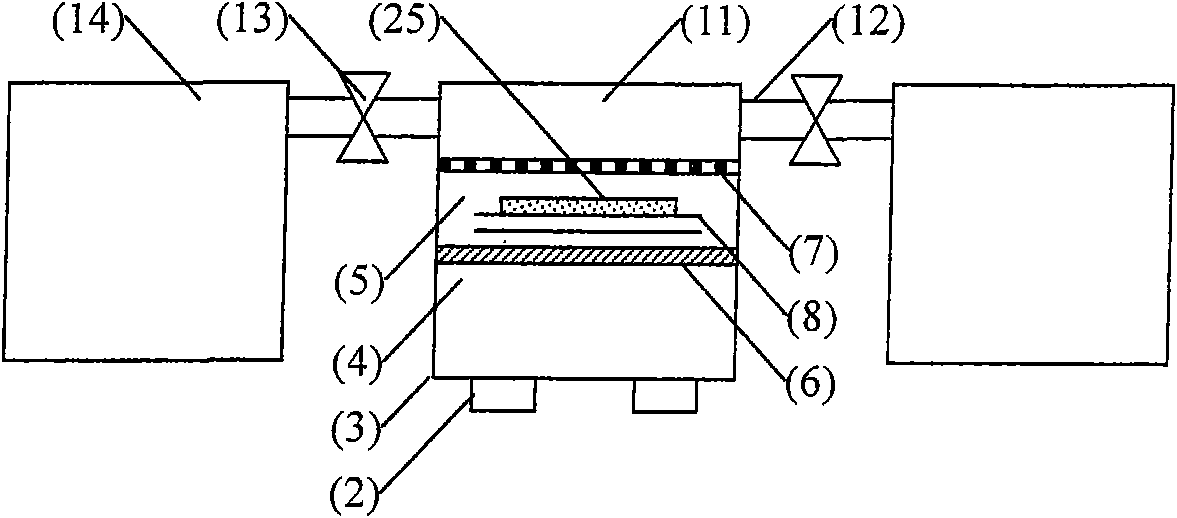

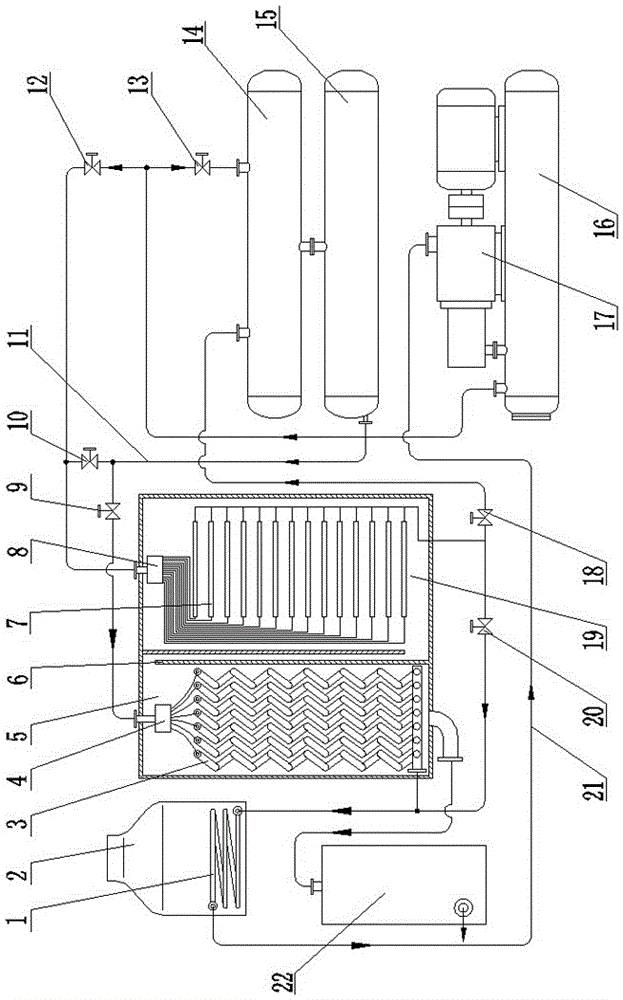

Microwave continuous freeze-drying system

InactiveCN101922855AIncrease profitEliminate breakdownDrying using combination processesDrying machines with progressive movementsMicrowave cavityVacuum pressure

The invention discloses a continuous vacuum freeze-drying system using microwave energy as a heat source, belonging to the technical field of freeze-drying. The system comprises a microwave vacuum freeze-drying device, a vacuum water catching device, a vacuum feed device and a vacuum discharge device, wherein the microwave vacuum freeze-drying device is internally provided with a combined type freeze-drying cabin consisting of a normal-pressure microwave cavity and a vacuum microwave cavity, and the normal-pressure microwave cavity and the vacuum microwave cavity are partitioned by a microwave-transmitted vacuum partition board; the vacuum microwave cavity is connected with a steam channel of the vacuum water catching device; and the vacuum microwave cavity and the steam channel are partitioned by a porous ventilate microwave shielding board. The invention solves the problem of microwave disruptive discharge within a vacuum pressure range required by freeze-drying, has the advantages of good sealing property, high utilization ratio and high freeze-drying speed and can be used for effectively realizing the application of automatic industrialization.

Owner:周川

Polypeptide freeze-drying composition with skin activity and preparation method thereof

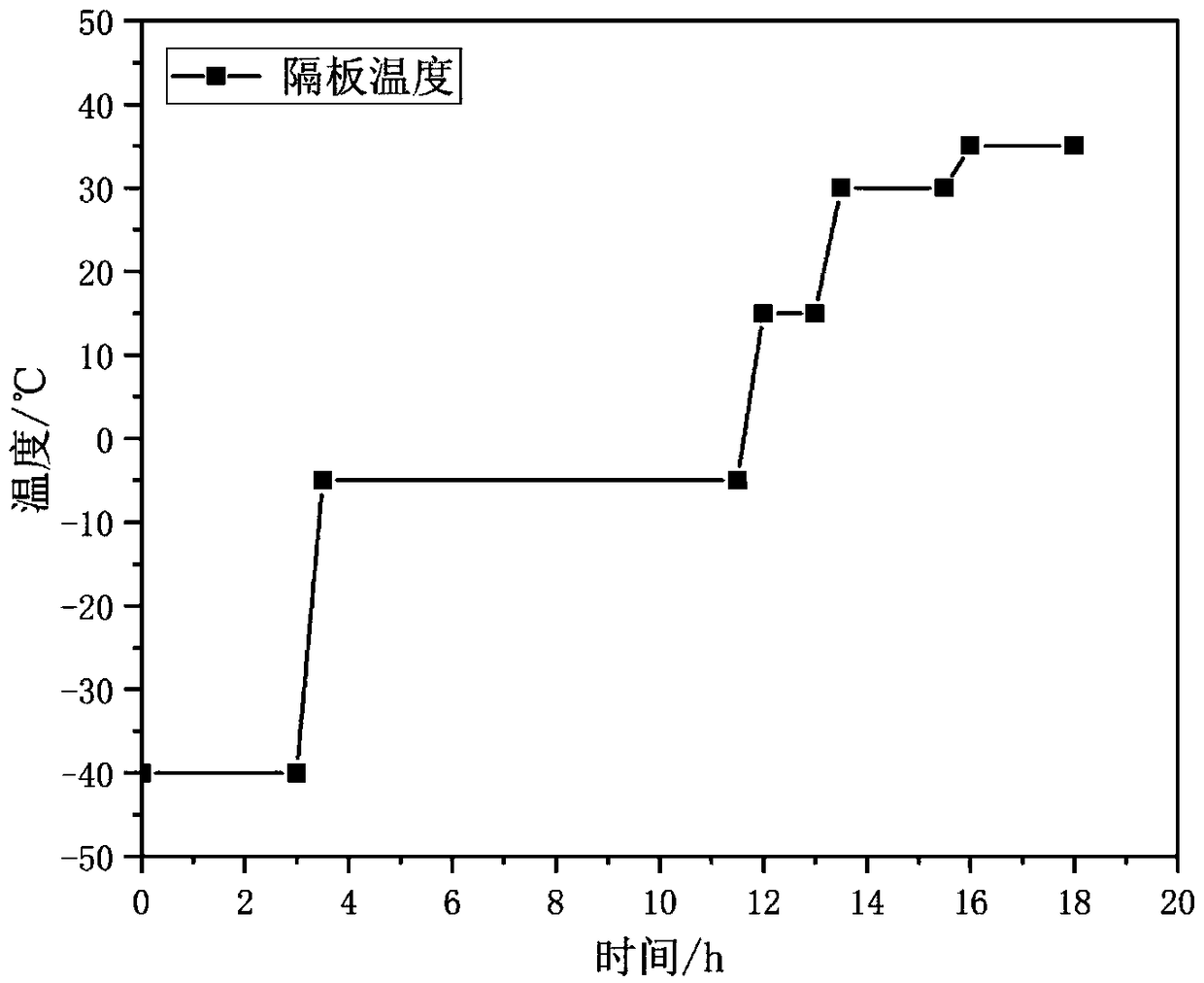

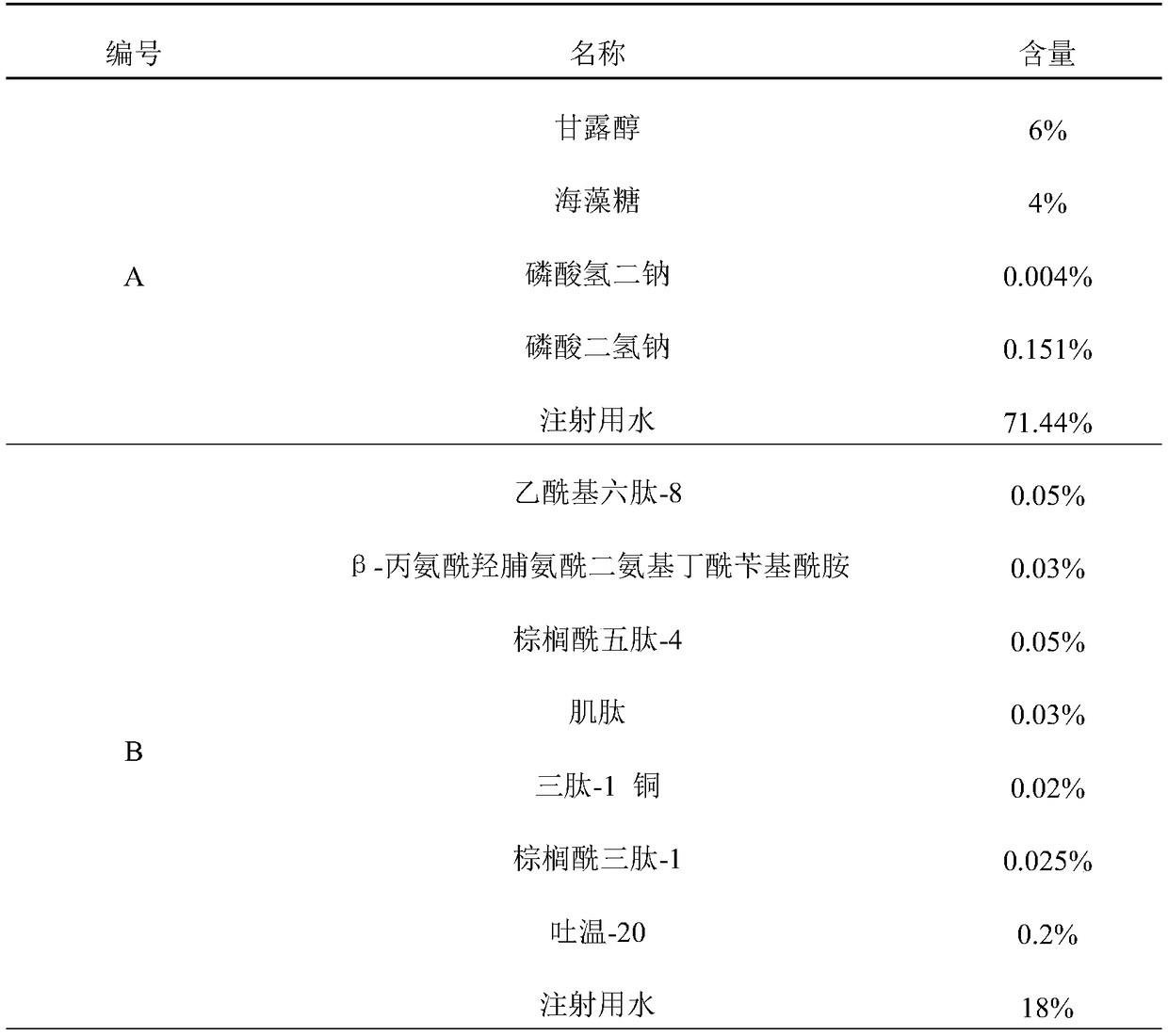

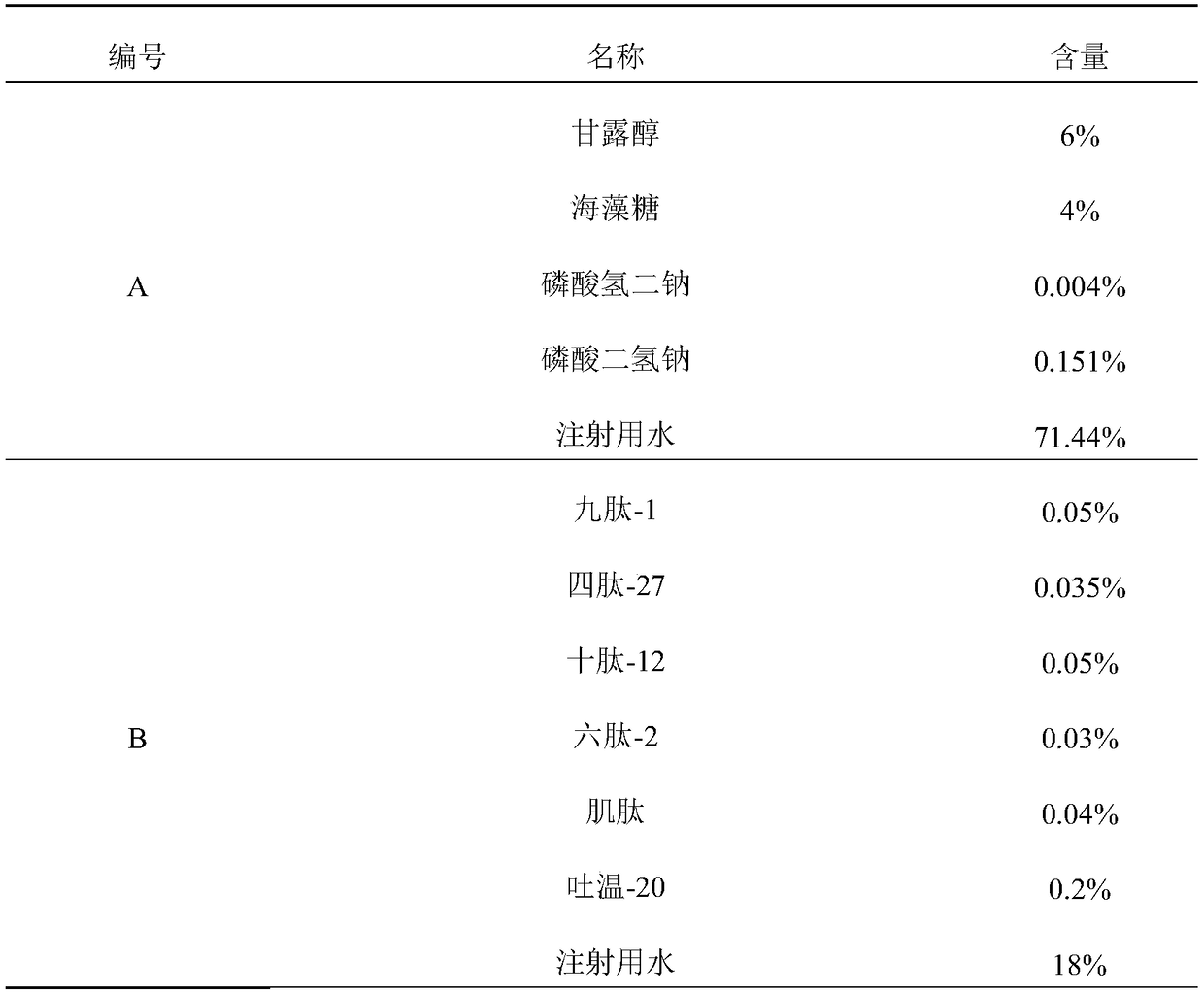

PendingCN109431849AFix stability issuesInhibit growthCosmetic preparationsHair cosmeticsWrinkle skinFreeze-drying

The invention discloses a polypeptide freeze-drying composition with skin activity and a preparation method thereof and belongs to the technical field of beauty polypeptide. The composition is prepared from polypeptide with skin activity, an excipient, a solubilizer and a pH buffer agent. The preparation method of the composition disclosed by the invention comprises the following steps: dissolving, mixing, filtering, sterilizing and filling all the ingredients; setting freeze drying according to a freeze-dry curve to obtain the polypeptide freeze-drying composition with the skin activity. Thepreparation method has the advantages of simple operation and mature and controllable technologies; furthermore, freeze drying is finished within 18h, so that the product quality is ensured; simultaneously, the production energy consumption is reduced, and the production cost is reduced. The polypeptide freeze-drying composition with skin activity prepared by the method has the advantages of goodstability, easiness in storage and no preservative addition. The composition disclosed by the invention is mainly applied to removing wrinkles, resisting senility, whitening the skin, removing freckles, relieving and resisting allergy, removing eye bags, developing hair and fixing hair, so that varieties of skin problems can be improved.

Owner:宇肽生物(东莞)有限公司

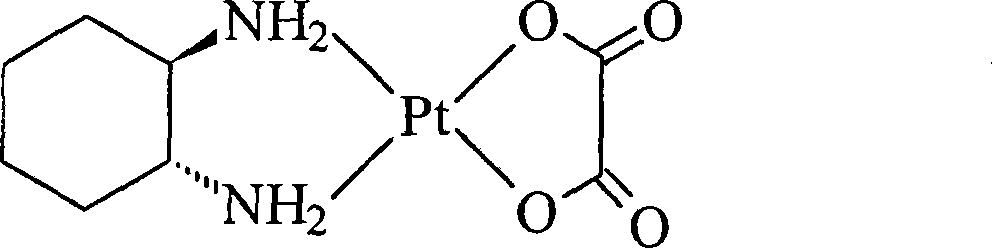

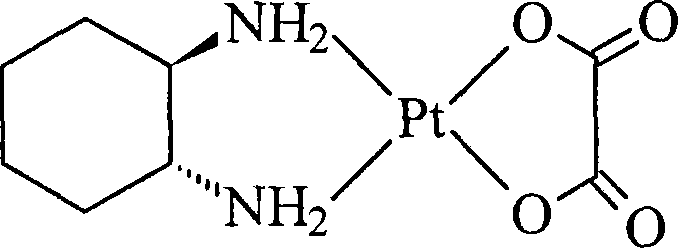

Oxaliplatin lyophilized powder injection and preparing method thereof

ActiveCN101199506AGood reproducibilityLess impuritiesPowder deliveryPharmaceutical non-active ingredientsCITRATE ESTERMANNITOL/SORBITOL

The invention relates to oxaliplatin freeze-dried injection, which is characterized in that the invention is prepared by the method that aqueous solution is freeze-dried. The aqueous solution contains oxaliplatin, mannitol and citrate, wherein, the concentration of the oxaliplatin in the aqueous solution is 2.5 to 6.25 mg / ml; the concentration of the mannitol in the aqueous solution is 25 to 200 mg / ml; and the concentration of the citrate in the aqueous solution is 2 to 20 mg / ml. And sodium citrate can also be added into the aqueous solution so as to adjust the pH of the aqueous solution. The preparation processes are as following: the oxaliplatin is placed inside the container, 80 percent amount of water for injection is added, and then the water for injection is mixed so that the oxaliplatin can be dissolved and mixed evenly in the water for injection; after that, the mannitol and the citrate are added into the water for injection, and then the water for injection is mixed so that the mannitol and the citrate can be dissolved and mixed evenly in the water for injection; the content of the intermediate is measured; if the content of the intermediate is qualified, the volume of the water for injection is fixed to full amount; in the aseptic condition, the water for injection is filtered until to be clear by a microporous membrane of 0.22 microns; the filtered solution is filled into an aseptic silin bottle; part of the aseptic silin bottle is plugged with a butyl rubber closure; and then the aseptic silin bottle is filled in the tray to be sent into the freeze dryer to be freeze-dried; the mouth of the aseptic silin bottle is rolled; the quality of the filtered solution is inspected; and the aseptic silin bottle is packaged.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Process for preparing thymic peptide

InactiveCN1390853AShorten production timeHigh yieldPeptide preparation methodsAnimals/human peptidesPeptideEnzyme

A process for preparing thymic peptide includes such steps as homogenizing fresh thymus gland, adding buffering solution (pH=2-4) for suppressing enzyme activity, breaking cell under 10 deg.C by ultrasonic waves, homogenizing machine and superfine technique, freeze centrifugalizing, ultrafiltering, nano filtering and concentrating. Its advantages are high output rate, high percentage of natural polypeptide, high activity and low cost.

Owner:西安迪赛生物药业有限责任公司 +1

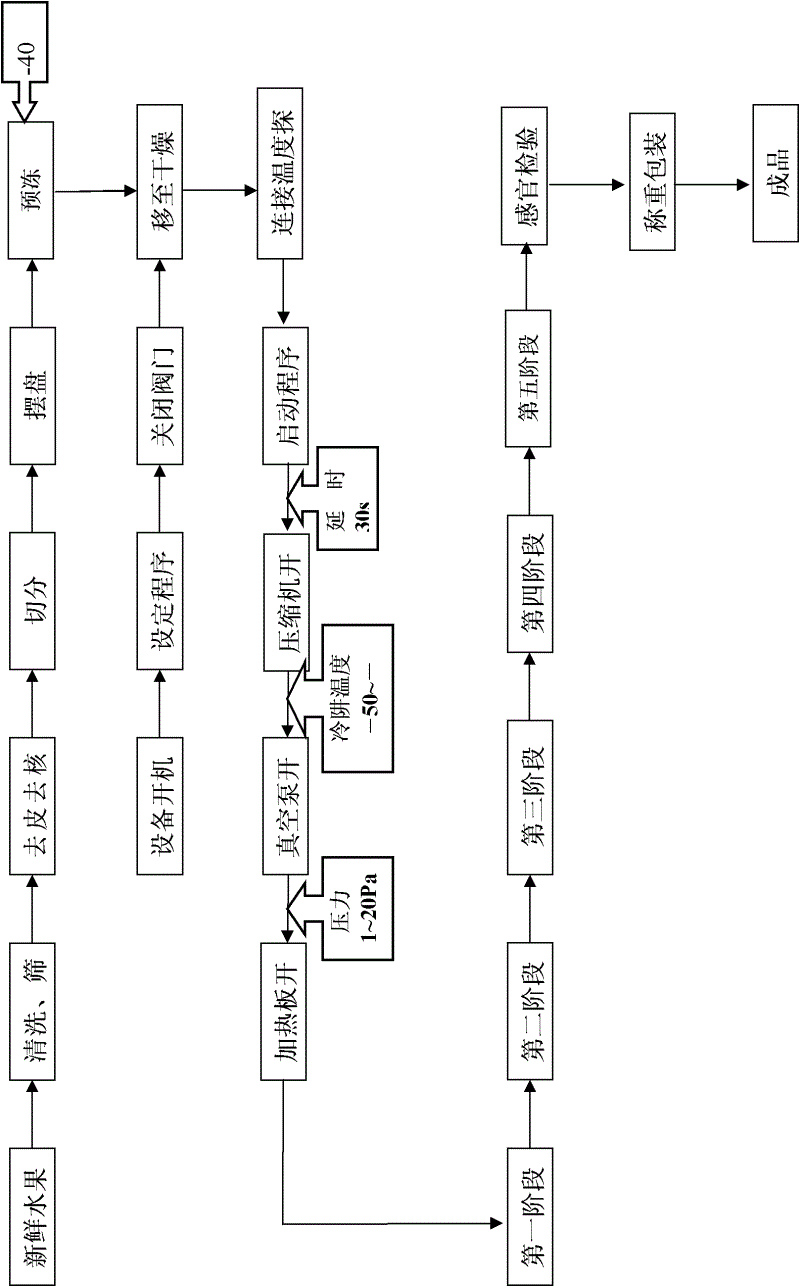

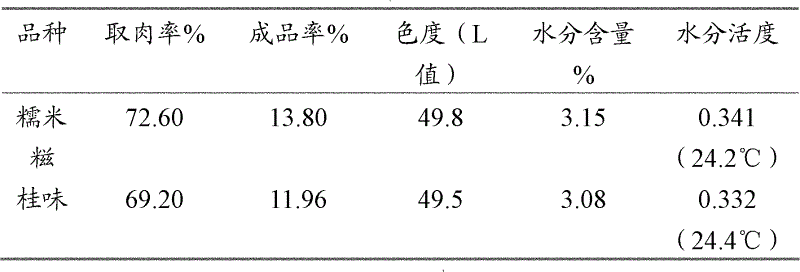

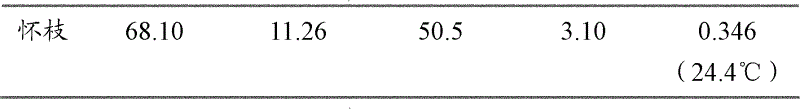

Fruit vacuum freeze drying method

ActiveCN102613283AInhibition of dissolutionSolution volumeFruit and vegetables preservationFreeze-dryingProcess engineering

The invention which is suitable for the technical field of drying provides a fruit vacuum freeze drying method. The method comprises the following steps: prefreezing: refrigerating fruits to be dried; and carrying out five-stage drying under vacuum conditions. The fruit vacuum freeze drying method of the invention, which adopts a five-step gradient cooling mode of the heating temperature, allows heat required by water sublimation to be guaranteed, cooling to be timely, the basic balance of the heat supply and demand to maintained, the material dissolving caused by too fast heating to be prevented, and the water sublimation rate to be accelerated.

Owner:SHENZHEN POLYTECHNIC

Method for producing freeze-dried whole donkey milk powder

The invention discloses a method for producing freeze-dried whole donkey milk powder, belonging to the technical field of food deep processing. The freeze-dried whole donkey milk powder is obtained through the steps of raw and fresh donkey milk inspection, milk purification, refrigeration, standardization, homogenization, sterilization concentration, prefreezing, vaccum drying, power recovery, pulverization, mixing and inspection. The donkey milk powder produced by using the method has small nutrient loss, good solubility, high rehydration, uniform product, attractive color and good taste.

Owner:新疆玉昆仑天然食品工程有限公司

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

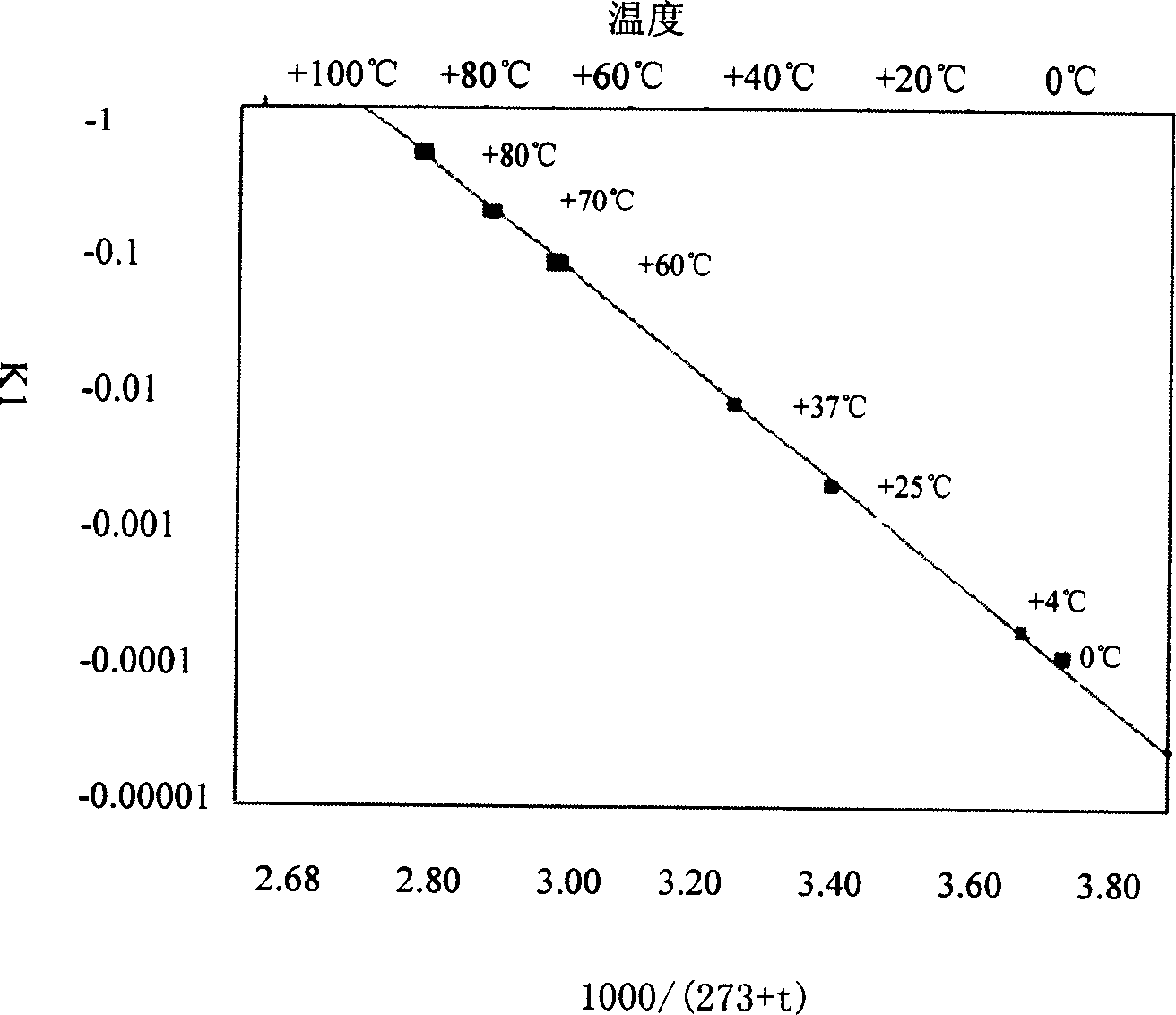

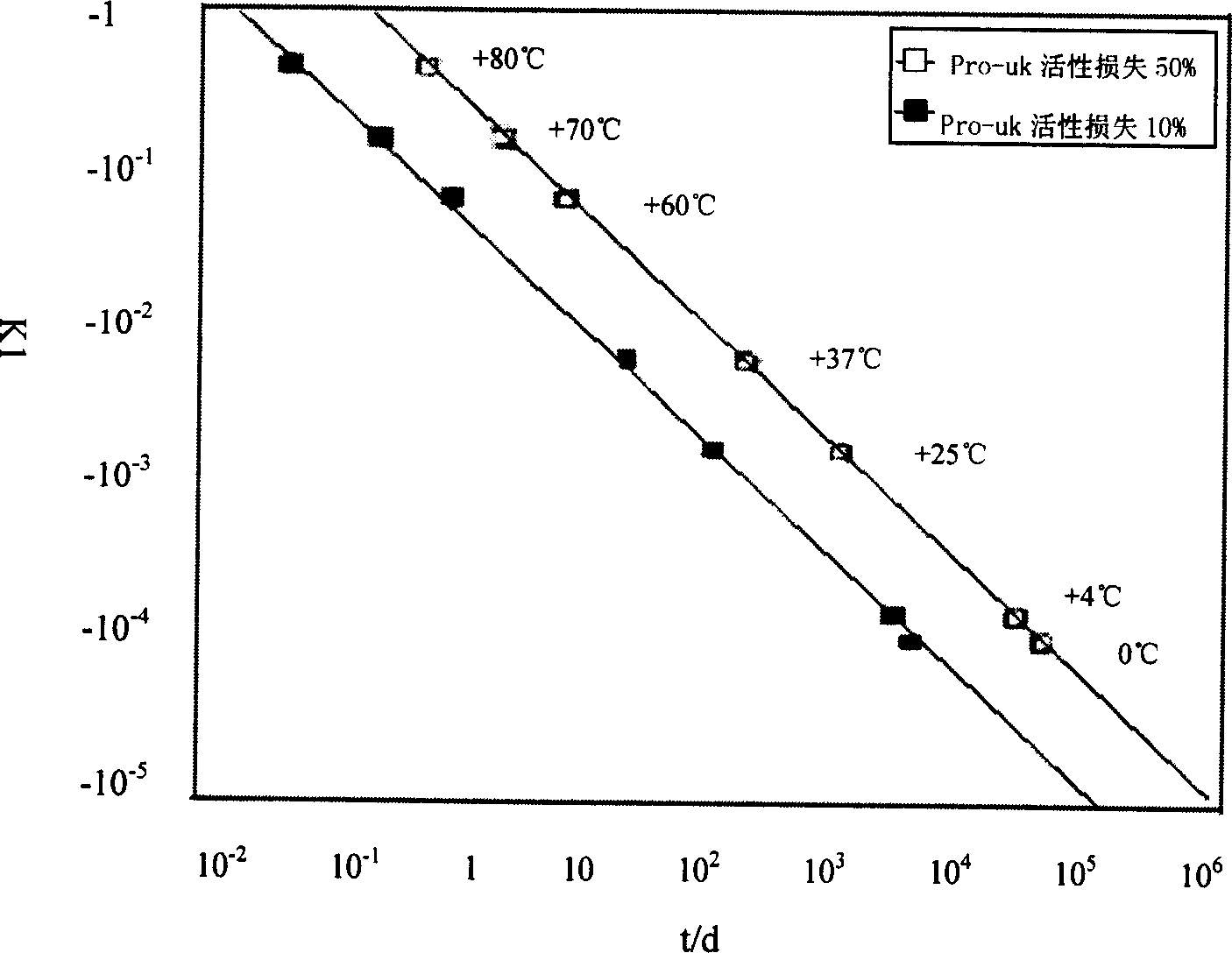

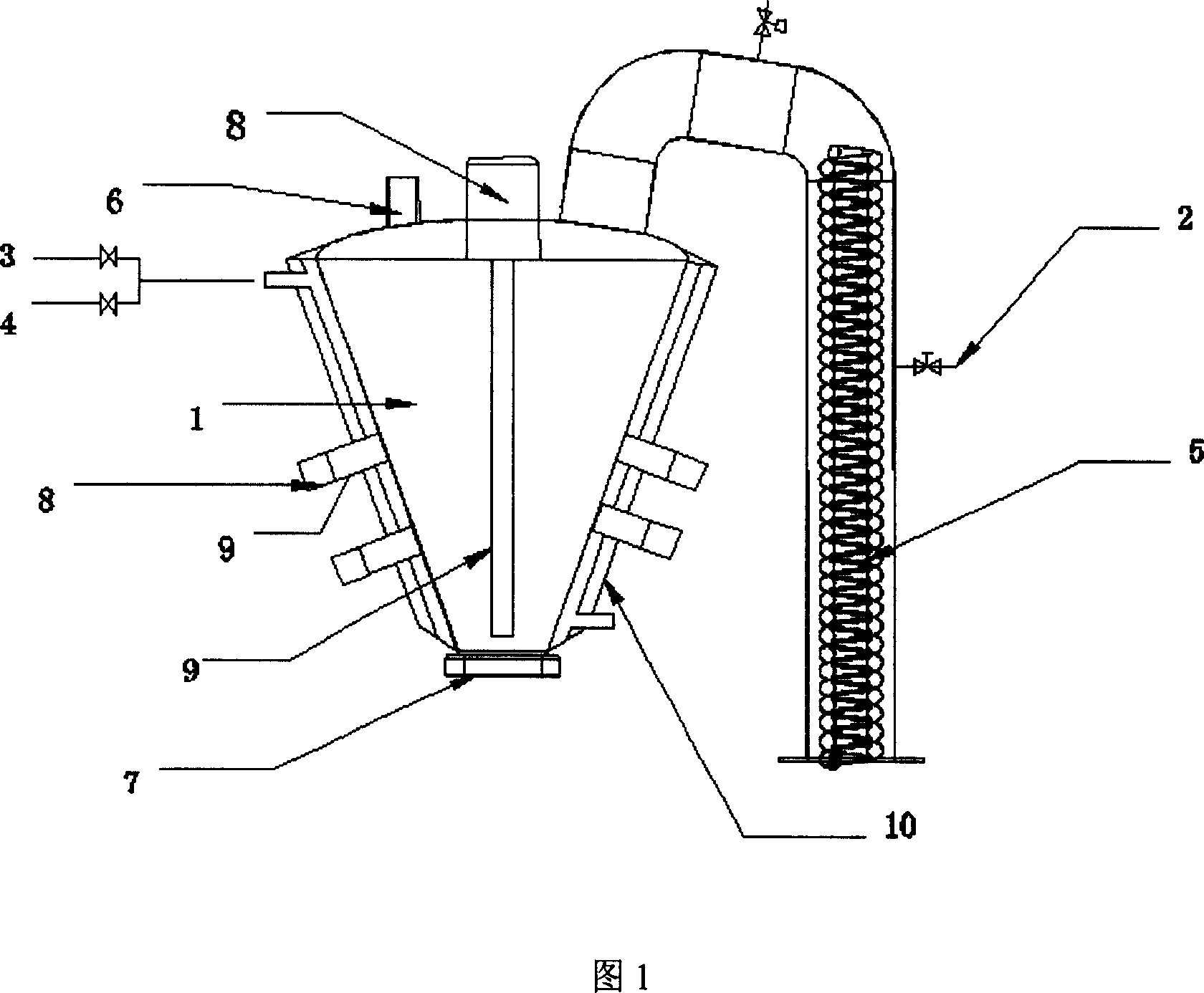

Composition containing active prourokinase, freeze-drying process and freeze-dried preparation thereof

ActiveCN1730098AFor long-term storageLow pricePowder deliveryPeptide/protein ingredientsFreeze-dryingPro-urokinase

Owner:TASLY BIOPHARMACEUTICALS CO LTD

Vacuum freeze drying processing method of shrimp meat

InactiveCN104187871ARetain nutrientsReduce moisture contentMeat/fish preservation by freezing/coolingFood preparationFreeze-dryingAdditive ingredient

The invention discloses a vacuum freeze drying processing method of shrimp meat. The vacuum freeze drying processing method comprises the following steps: 1, blanching shrimp meat with hot water, and immediately cooling the blanched shrimp meat with cold water; 2, soaking the blanched and cooled shrimp meat in a seasoning solution for seasoning, and then performing second direct mixing for seasoning after draining; 3, putting the seasoned and drained shrimp meat on a dish, and pre-freezing in a quick-freezing refrigerator; and 4, reducing the temperature in a condensation cylinder to -25 DEG C, starting vacuumizing to perform vacuum freeze drying, keeping negative pressure for 6h-8h after the temperature in a drying bin rises to 30-35 DEG C and the vacuum degree reaches 4Pa below, slowly pressurizing to normal pressure, and then taking the shrimp meat out. The shrimp meat is subjected to vacuum freeze drying, the shapes and tissue structures of the shrimp meat can be kept, the quality and the mouth feel of the cooked shrimp meat are basically kept after the shrimp meat is soaked in hot water to be rehydrated, and thus the shrimp meat is especially suitable for being added into a convenient food as an important auxiliary material or an ingredient.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Method for preparing active pseudo-ginseng

InactiveCN101961361ANot transgenderHigh content of active ingredientsNervous disorderMetabolism disorderVacuum pressureHeat conducting

The invention relates to a drying process of a specific plant. The process comprises the following steps of: 1. pretreatment: sorting prepared fresh pseudo-ginsengs; after separating and removing pruning openings, fibrous roots and flocking roots attached to the fresh pseudo-ginseng roots, obtaining main pseudo-ginseng roots; cleaning and removing surface attachments and leaching surface water; 2. pre-freezing: directly placing the whole main pseudo-ginseng roots into a pre-freezing chamber at minus 15-minus 20 DEG C and pre-freezing for 6-7 hours; 3. sublimation drying: spreading the pre-frozen main pseudo-ginseng roots on a table disk made of heat conducting materials, controlling the thickness of a paving material to be below 5cm and shifting to a vacuum drying chamber; after sealing, vacuumizing, maintaining internal vacuum pressure at 30-70Pa, setting the temperature of the table disk to be 40 DEG C, continuously supplying heat to the table disk and carrying out sublimation drying in vacuum for 10-15 hours till the table disk is heated to 40 DEG C; 4. analysis: maintaining the temperature of the table disk to be 40 DEG C and continuously supplying heat to the table disk and vacuumizing for 10-12 hours till the material is heated to 40 DEG C and material water is controlled to be below 3 percent; and 5. discharging and packaging. The invention provides a method for preparing active pseudo-ginseng.

Owner:云南特安呐制药股份有限公司

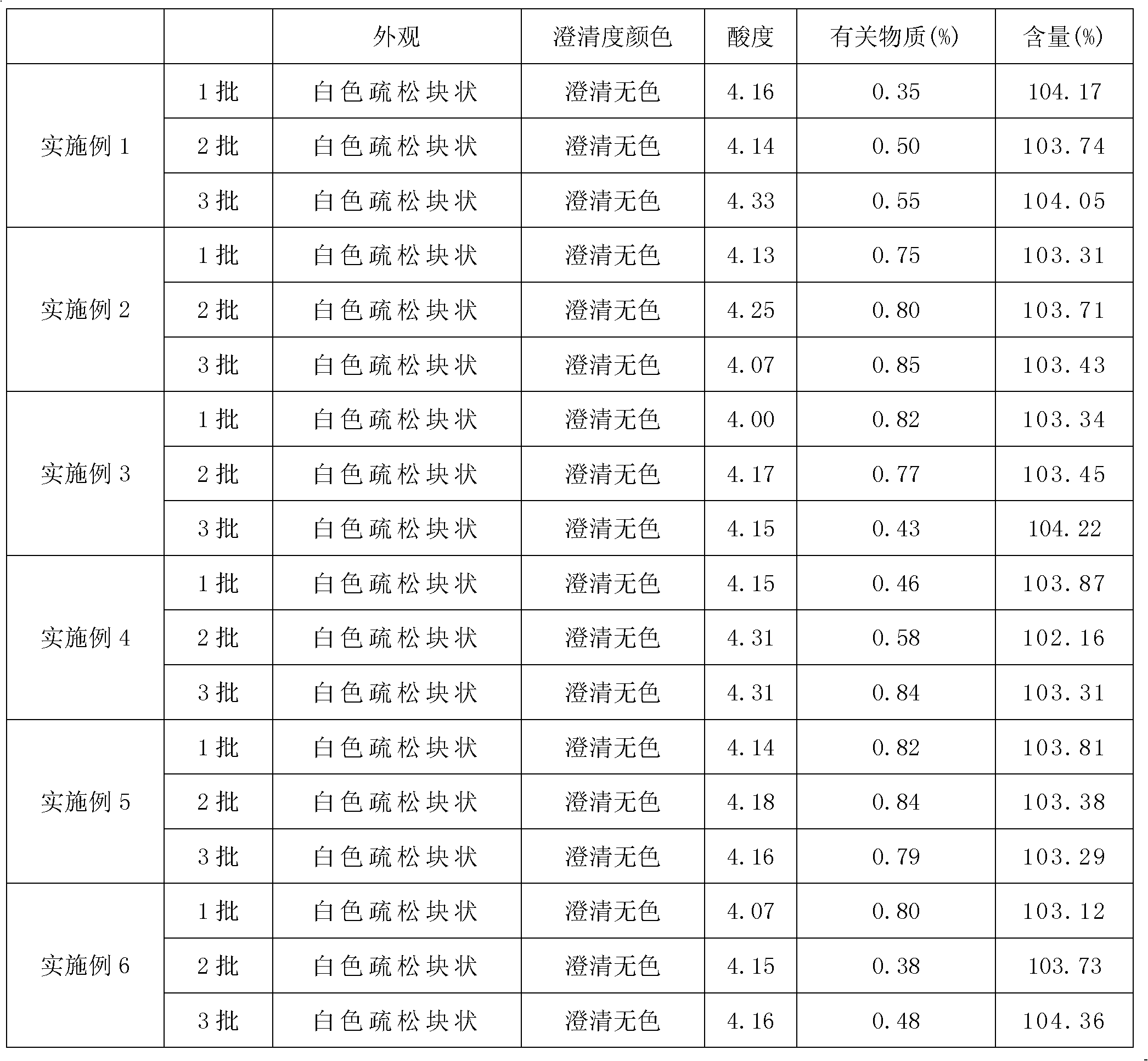

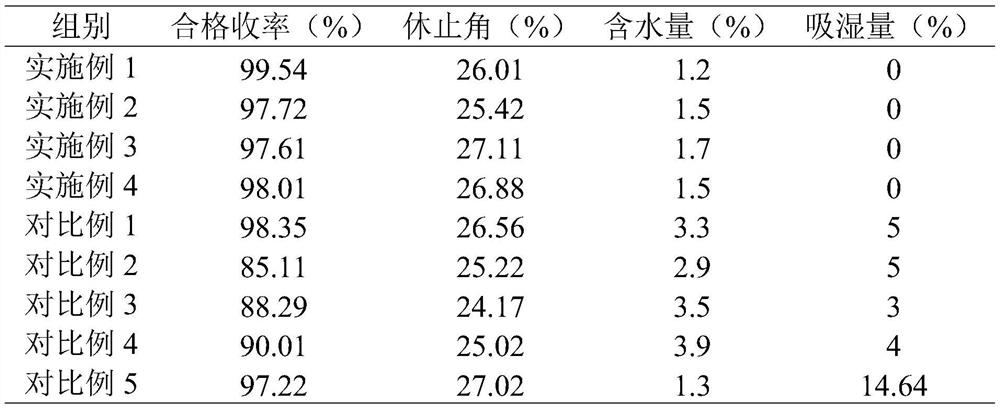

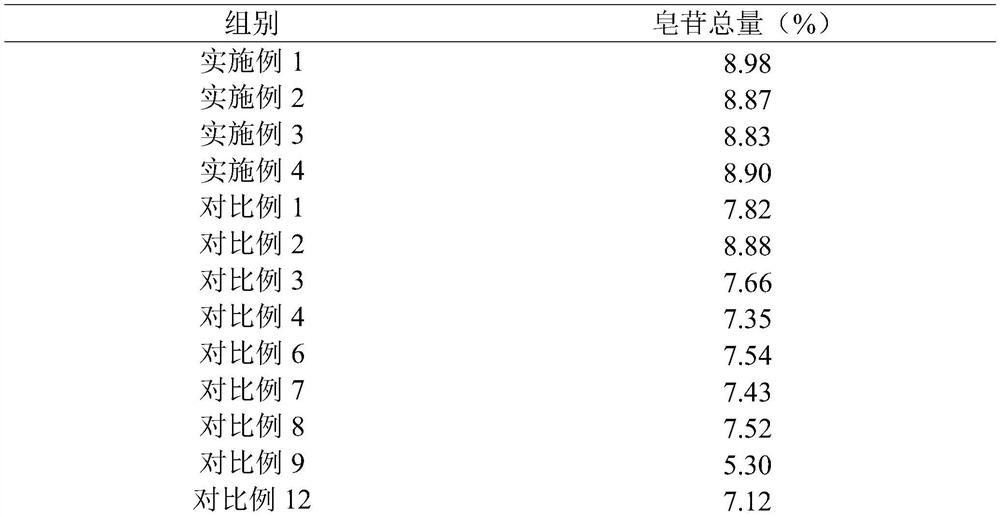

Panax notoginseng saponins freeze-dried powder injection and preparation method thereof

ActiveCN102512466AGood resolubilityReduce moisture contentPowder deliveryPharmaceutical product form changePANAX NOTOGINSENG ROOTFreeze-drying

The invention relates to panax notoginseng saponins freeze-dried powder injection and a preparation method thereof. The freeze-dried powder injection is prepared by panax notoginseng saponins and water for injection. The panax notoginseng saponins freeze-dried powder injection is free of auxiliary materials or stent agents, good in re-dissolubility, low in water content and good in appearance forming.

Owner:GUANGXI WUZHOU PHARMA GRP

Supersonic freeze drying method and apparatus

InactiveCN101126593AQuick conversionFast heatingDrying solid materials without heatThermal energyFreeze-drying

The utility model discloses an ultrasonic freeze drying process, relating to the technical field of the freeze drying agent, mainly comprising that after the materials are dissolved in a suitable solvent, the material can be handled with the continuous ultrasonic assistance; under the vacuum freezing condition, the solvent are deeply frozen into solid state; the heat energy is continuously supplied, making the solvent in the materials sublimed into vapor state directly from the solid state; the drying process is completed after the vapor is pumped out by the vacuum system. The equipment of the utility model comprises a closed vessel, a cooling and heating system, a vacuum system, an ultrasonic device, and the relating heat insulation and sealing device. The ultrasonic freeze drying process is characterized in rapid drying speed, high production efficiency, and small labor intensity. The process and the equipment can be applied to the drying fields of the medicine, food, chemistry and other respects.

Owner:PHARM TECH TIANJIN

Netilmicin sulfate lyophiled powder injection and preparation method thereof

ActiveCN102525963AGuaranteed singleImprove bioavailabilityAntibacterial agentsOrganic active ingredientsSodium bicarbonateBletilla striata

The invention discloses netilmicin sulfate lyophiled powder injection and a preparation method of the netilmicin sulfate lyophiled powder injection. Netilmicin sulfate and additives are added with water to be prepared into netilmicin sulfate injectable suspension, and the netilmicin sulfate lyophiled powder injection is obtained through freeze drying, wherein the additives are inclusion moleculesand pH conditioning agents, the inclusion molecules are selected from bletilla striata polysaccharide, beta-cyclodextrin, urea, thiourea, beta-cyclodextrin derivatives, deoxycholic acid and starch, and the pH conditioning agents are selected from sodium carbonate, sodium bicarbonate, ammonia water, sulfuric acid and phosphoric acid. Required auxiliary materials are few, the preparation process issimple, the freeze drying process is particularly screened and optimized, and the netilmicin sulfate lyophiled powder injection and the preparation method has the characteristics that the stability is high, the biological availability is high, the production cost is low, the quality is safe and reliable, and the like.

Owner:WUHAN PUSHENG PHARMA

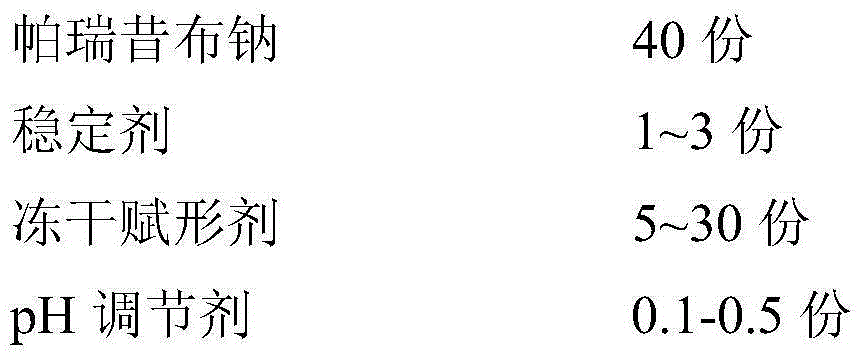

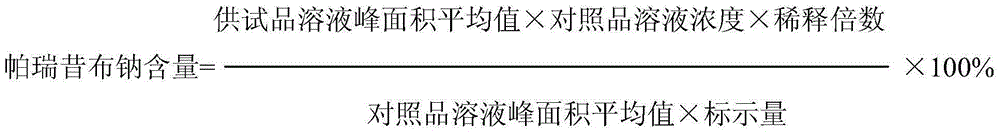

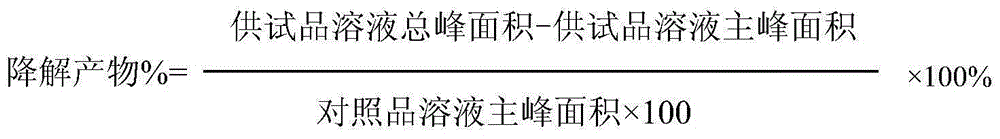

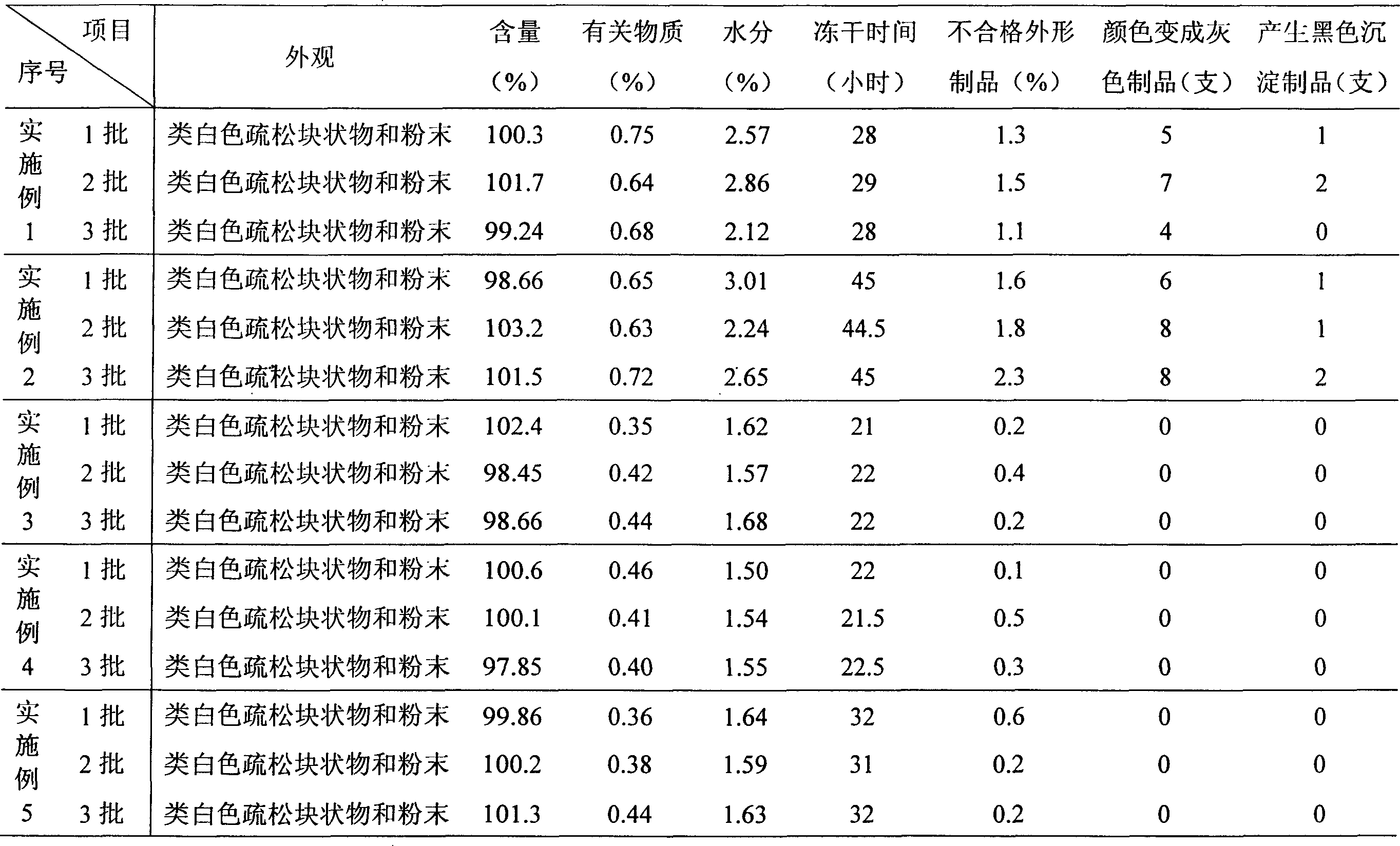

Lyophilized parecoxib sodium powder and preparation method thereof

ActiveCN105168152APrevent the formation of degradation productsShorten freeze-drying timePowder deliveryAntipyreticChemistryTreatment effect

The invention discloses lyophilized parecoxib sodium powder and a preparation method thereof. The lyophilized parecoxib sodium powder comprises, by mass, 40 parts of parecoxib sodium, 1-3 parts of stabilizers, 5-30 parts of lyophilization excipients and 0.1-0.5 part of pH (potential of hydrogen) regulators. The preparation method includes the steps of 1) mixing the lyophilization excipients, water and medicinal carbon with stirring, and filtering to obtain a solution I; 2) mixing the stabilizers, the water and the parecoxib sodium with stirring so as to obtain a solution II; 3) mixing the solution I with the solution II and filtering to obtain a solution III; 4) lyophilizing the solution III to obtain the lyophilized parecoxib sodium powder. A lyophilized parecoxib sodium composition prepared by the preparation method has the advantages that since the parecoxib sodium is degraded difficultly, 'degradation product' content is extremely low and stability during long-term storage is high; treatment effect and safety of the lyophilized parecoxib sodium composition during clinical application are greatly improved.

Owner:上海华源药业(宁夏)沙赛制药有限公司

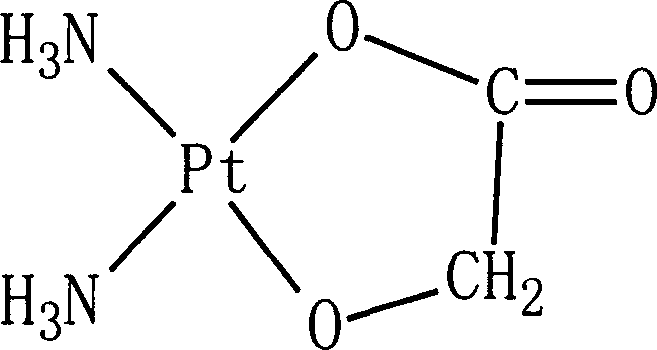

Preparation of nedaplatin freeze-dried powder injection

ActiveCN101015539AImprove stabilityLow content of related substancesPowder deliveryLyophilised deliveryFreeze-dryingBottle

This invention relates to a preparation method of freeze-dried injection of nedaplatin.nedaplatin freeze-dried injection prepared with the inventive method can be used as therapeutic drug of cancer. The invention improves the stability of nedaplatin during lyophilization and shortens the period of lyophilization through adding ethanol during preparation process. the preparation method comprises adding water for injection 80% of nedaplatin into nedaplatin, stirring for dissolving, adding dextran, stirring for dissolving, determing the content of intermediate, adding ethanol 1-10% of the cumulative volume of the solution, adding water for injection to full dose, filtrating with 0.22 mu m millipore filter under aseptic condition, encapsulating in sirin bottle, plugging, freeze drying, rolling the opening, testing, and packaging. The optimum amount of ethanol is 1-5% of cumulative volume of the solution.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Injectable pharmaceutical compositions of an anthracenedione derivative with anti-tumoral activity

InactiveUS20060199831A1Shorten freeze-drying timeReduce processing costsPowder deliveryBiocideIsoquinolineLactose

Injectable pharmaceutical compositions containing 6,9-bis[(2-aminoethyl)amino]benzo[g]isoquinoline-5,10-dione dimalcate as active ingredient in the form of a lyophilised powder with a carrier selected from lactose and dextran, mixed with sodium chloride.

Owner:CELL THERAPUETICS INC

Roxatidine acetate hydrochloride used for injection and preparation method thereof

InactiveCN102018677AQuality assuranceQuality improvementOrganic active ingredientsPowder deliveryGlycineMANNITOL/SORBITOL

The invention provides roxatidine acetate hydrochloride used for injection and a preparation method thereof. The roxatidine acetate hydrochloride is prepared by taking the roxatidine acetate hydrochloride as a raw material; adding glycine or mannitol as an excipient; and freezing and drying after preparing the raw material and the excipient into a liquid medicament. The prepared roxatidine acetate hydrochloride used for the injection is used for upper gastrointestinal hemorrhage caused by gastric ulcer, stress ulcer and hemorrhagic gastritis and preanesthetic medication. The product obtained by the method has good quality, exact curative effect and stable quality.

Owner:哈药集团人民同泰医药股份有限公司

Pseudo-ginseng vacuum freeze-drying method and application thereof

InactiveCN112229148APrevent local melting and disintegrationAvoid affecting product qualityDrying solid materials without heatDaily livingFreeze-drying

The invention relates to a pseudo-ginseng vacuum freeze-drying method and application thereof, and relates to the technical field of traditional Chinese medicine processing. According to the vacuum freeze-drying method, pseudo-ginseng homogenate is subjected to pre-freezing and vacuum drying treatment, in the pre-freezing step, pre-freezing is carried out in stages at the temperature of minus 20-minus 75 DEG C, and in the vacuum drying treatment step, vacuum drying is carried out at the temperature of minus 20-30 DEG C. The vacuum freeze-drying method is applied to preparation of pseudo-ginseng processed products, and the obtained pseudo-ginseng processed products are high in cleanliness, fine and smooth in taste, stable in quality, accurate in dosage, convenient to apply and carry, high in dissolution and absorption speed, higher in product standardization, higher in production efficiency and suitable for daily life of normal people.

Owner:湖北金贵中药饮片有限公司

Freezing and drying integrated vacuum freezing and drying machine

InactiveCN106679353ARaise the suction temperatureShorten drying timeDrying solid materials without heatCompression machines with non-reversible cycleRefrigeration compressorEvaporation

The invention relates to a drying device, in particular to a freezing and drying integrated vacuum freezing and drying machine. The machine comprises a freezing and drying evaporation bin, a freezing evaporation plate arranged in the freezing and drying evaporation bin, a water catching bin, a refrigeration compressor unit, a vacuum pump and an electrical control cabinet, wherein the refrigeration compressor unit is composed of a refrigeration compressor, an oil separator, a condenser and a liquid storage device. The freezing and drying integrated vacuum freezing and drying machine is characterized in that the part between the closed freezing and drying evaporation bin and the closed water catching bin is partitioned through two parallel partition plates, a closed cavity is formed between the two parallel partition plates, a ventilation hole is formed in the lower end of the partition plate on one side of the freezing and drying evaporation bin, and a ventilation hole is formed in the upper end of the water catching bin partition plate on one side of the water catching bin. The refrigeration compressor is connected with the freezing and drying evaporation bin and the water catching bin through a pipeline, and the vacuum pump is connected with the bottom of the water catching bin. The technical scheme has the beneficial effects that the equipment configuration and structure are more reasonable, the equipment running efficiency is high, and the service life is long. The production cost and the using cost of the equipment can be reduced by about 10%-20% compared with current vacuum freezing and drying equipment.

Owner:YINCHUAN LIZHIXIN INTPROP ADVISORY SERVICES

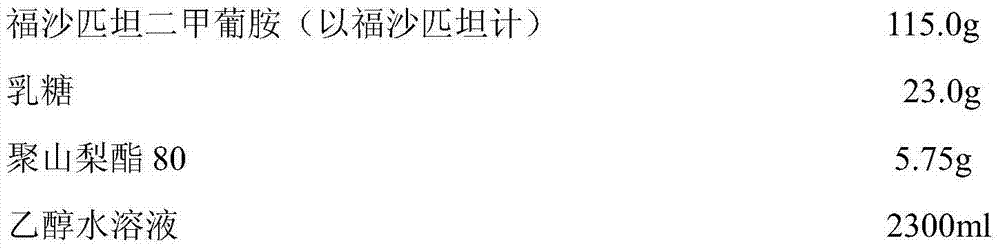

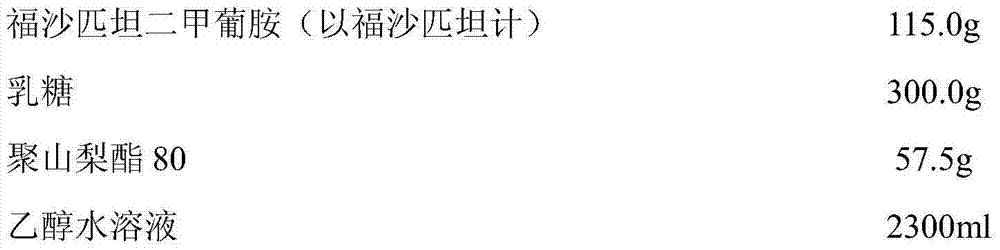

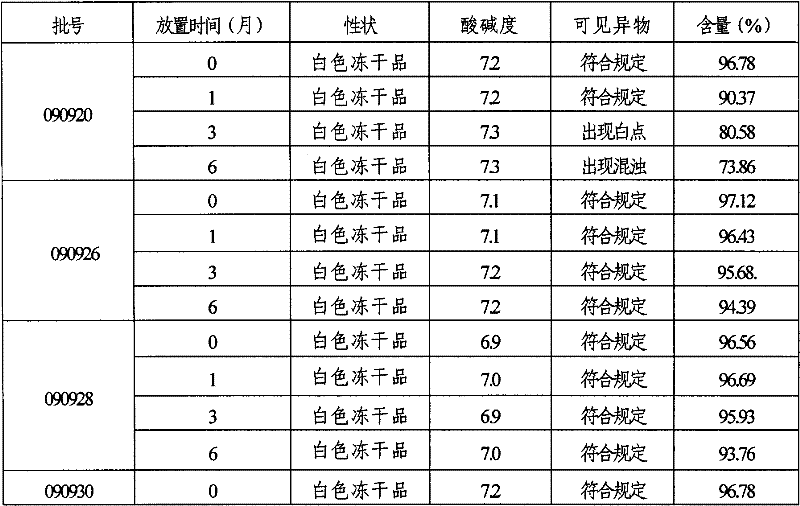

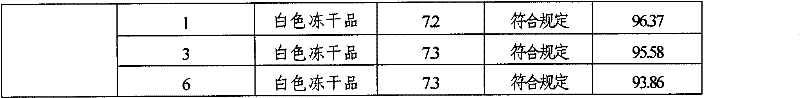

Fosaprepitant dimeglumine freeze-dried powder and preparation method thereof

InactiveCN103565760AShorten freeze-drying timeReduce manufacturing costPowder deliveryOrganic active ingredientsFreeze-dryingFosaprepitant dimeglumine

The invention discloses fosaprepitant dimeglumine freeze-dried powder and a preparation method thereof, and relates to the technical field of drugs and drug production. The freeze-dried powder injection contains fosaprepitant dimeglumine, lactose, polysorbate 80 and ethanol water solution. The freeze-dried powder adopts the ethanol water solution as freeze-dried preparation solvent, so that the freeze-dried time is largely shortened, the energy consumption is decreased, and the production cost is reduced.

Owner:NANJING CORE TECH CO LTD

Urotropin freeze-dried powder injection and preparation method thereof

InactiveCN102293756APlay a protective effectReduce contentPowder deliveryPeptide/protein ingredientsArginineFreeze-drying

The invention relates to a urethrotropin freeze-dried powder injection and a preparation method thereof. In every 1 mg freeze-dried powder injection: the active ingredient is 60-200 units based on the titer of follicle-stimulating hormone, and the auxiliary materials are L-arginine, The composition of mannitol and phosphate buffer salt is 4-8:20-40:2.0-6.0 according to the weight ratio. The formula of the present invention prevents the urea gonadotropin from existing in the aqueous solution state for a long time in the preparation process, reduces the freeze-drying time, and increases the stability of the urea gonadotropin freeze-dried powder injection.

Owner:蚌埠丰原涂山制药有限公司

Preparation method of active pseudo-ginseng slices

ActiveCN101961363AHigh content of active ingredientsEasy to storeNervous disorderMetabolism disorderSurface moistureInternal pressure

The invention relates to a drying process method of a specific plant. The method comprises the following steps of: (1) pretreatment: sorting and selecting prepared fresh pseudo-ginseng, separating and removing snips, fibrous roots and flocking roots attached to the fresh pseudo-ginseng roots to obtain pseudo-ginseng main roots, cleaning and removing surface attachments, draining surface moisture, and cutting into 0.2-2 mm slices by using a slicing machine; (2) pre-freezing: directly placing the slices in a pre-freezing room with the set temperature of subzero 15 to subzero 20 DEG C, and pre-freezing for 5-6h; (3) sublimation drying: spreading the pre-frozen slices out on a desk tray made of a conducting material, controlling the spreading thickness to be below 5 cm, and moving to a vacuum drying room; sealing, starting vacuumizing, maintaining the internal vacuum pressure at 30-70 pascals, setting the temperature of the desk tray to be 40 DEG C, keeping supplying heat for the desk tray, and carrying out vacuum sublimation drying for 7-10h until the temperature of the desk try reaches 40 DEG C; (4) analysis: maintaining the temperature of the desk tray to be 40 DEG C, keeping supplying heat for the desk tray and vacuumizing for 6-12h until the temperature of the material reaches 40 DEG C, and controlling the moisture of the material at 3-5%; and (5) discharging and packaging.

Owner:云南特安呐制药股份有限公司

High-solubility compound protein powder and preparation method thereof

InactiveCN105919104AImprove frost resistanceImprove biological activityVegetable proteins working-upFood additiveSolubility

The invention discloses high-solubility compound protein powder and a preparation method thereof. Soybean protein isolate, whey protein concentrate and phospholipid are taken as main raw materials, stevia rebaudiana is processed into a stevia rebaudiana extract at low temperature, the effective ingredients and the bioactive ingredients of the stevia rebaudiana can be maximumly retained, the extraction rate is high, the flavor is pure, the color and cluster are natural, no licorice taste exists, the stevia rebaudiana extract is scientifically compounded with main materials, antifreeze polypeptides, dietary fiber flour, bee pupa hydrolysates and wheat malt powder are added, and then the compound protein powder which is appropriate in mouthfeel, good in solubility, comprehensive in nutrition, high in bioactivity and wide in suitable crowd is prepared. According to the preparation method, a non-thermal processing technique is adopted, the working efficiency is high, energy consumption is little, environmental friendliness is achieved, no pollution is generated, introduction of food additives and chemical auxiliaries is reduced, the food safety is effectively improved, the product quality is improved, the production cost is reduced, the low-carbon production objective is achieved, and large-scale and industrialized development can be achieved.

Owner:义乌市忻昱生物科技有限公司

Freeze-dried powder of fruit and vegetable extracts and preparation method of freeze-dried powder

InactiveCN105795300AImprove food safetyRetain natural colorNatural extract food ingredientsFood dryingCryoprotective EffectNutritive values

The invention discloses freeze-dried powder of fruit and vegetable extracts. Fruits and vegetables are taken as raw materials, a low-temperature extraction technology is adopted in the whole process, and obtained extracts keep natural color, flavor and taste of the fruits and the vegetables to the greatest extent; an anti-freeze agent which is prepared from natural plant raw materials and has a remarkable cryoprotective effect replaces traditional and existing cryoprotective agents in the vacuum freeze drying process of extracts, the freeze loss caused by a freeze-drying process is further greatly reduced, biological activity and nutritional value of the freeze-dried powder of the extracts are effectively improved, the freeze-dried powder of the extracts is scientifically compounded with functional dietary fiber powder, prebiotic factors and lactobacillus plantarum powder, the medicine and food nutrition balance property as well as functionality, solubility and the probiotic property of the freeze-dried powder of the extracts is remarkably improved, the guarantee period of a product is prolonged, and finally, the freeze-dried powder of fruit and vegetable extracts is prepared, contains more nutritional substances and bioactive substances and is high in function, good in anti-freezing effect and solubility and low in cost.

Owner:邵素英

Low-temperature and low-pressure freeze-drying method of pseudo-ginseng chewable tablets

ActiveCN104482720AGood lookingGreat tasteDrying solid materials without heatPreliminary solid treatment for dryingFreeze-dryingPhenolic content in tea

The invention discloses a low-temperature and low-pressure freeze-drying method of pseudo-ginseng chewable tablets. The low-temperature and low-pressure freeze-drying method comprises the steps of (1) preprocessing, namely cleaning fresh pseudo-ginseng main roots and draining off the moisture content, slicing and spraying tea polyphenol aqueous solution and sweet aqueous solution onto the pseudo-ginseng slices, (2) pre-freezing, namely putting the pseudo-ginseng slices obtained in the step (1) into a vacuum drier, reducing the temperature to the range of -30 to -40 DEG C and freezing the pseudo-ginseng slices, (3) vacuum freeze-drying, namely vacuumizing the vacuum dryer to keep the pressure within the range of 10-20Pa, keeping for 1-2 hours, heating to increase the temperature to 0 DEG C from the range of -30 to -40 DEG C within 20-30 hours, reheating, and increasing the temperature to 20 DEG C from 0 DEG C within 2-4 hours; taking out the obtained pseudo-ginseng chewable tablets from the vacuum dryer. The low-temperature and low-pressure freeze-drying method of the pseudo-ginseng chewable tablets is low in cost, and capable of effectively keeping the content of effective constituents of the prepared pseudo-ginseng chewable tablets and guaranteeing excellent freeze-dried product appearance and good taste.

Owner:ZHEJIANG JIANFENG HEALTH TECH

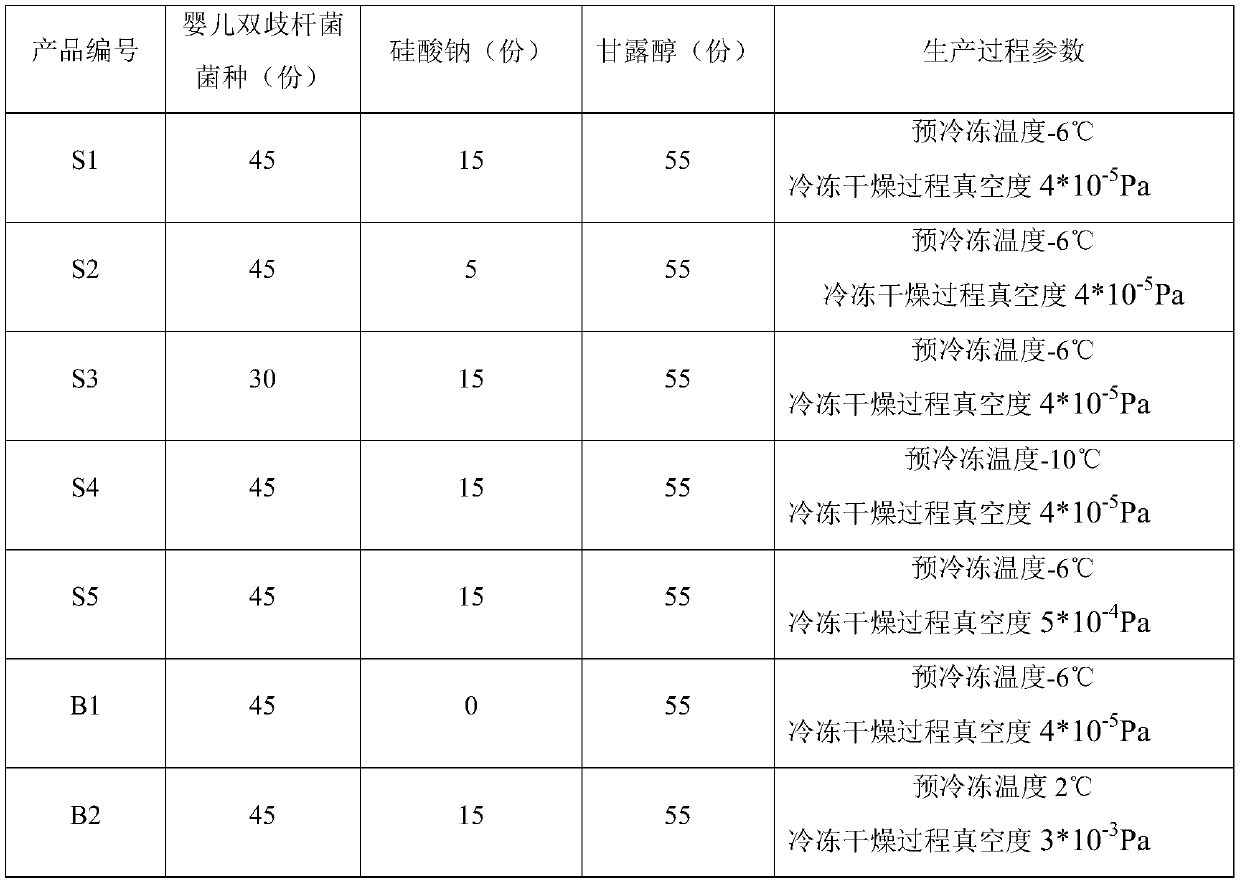

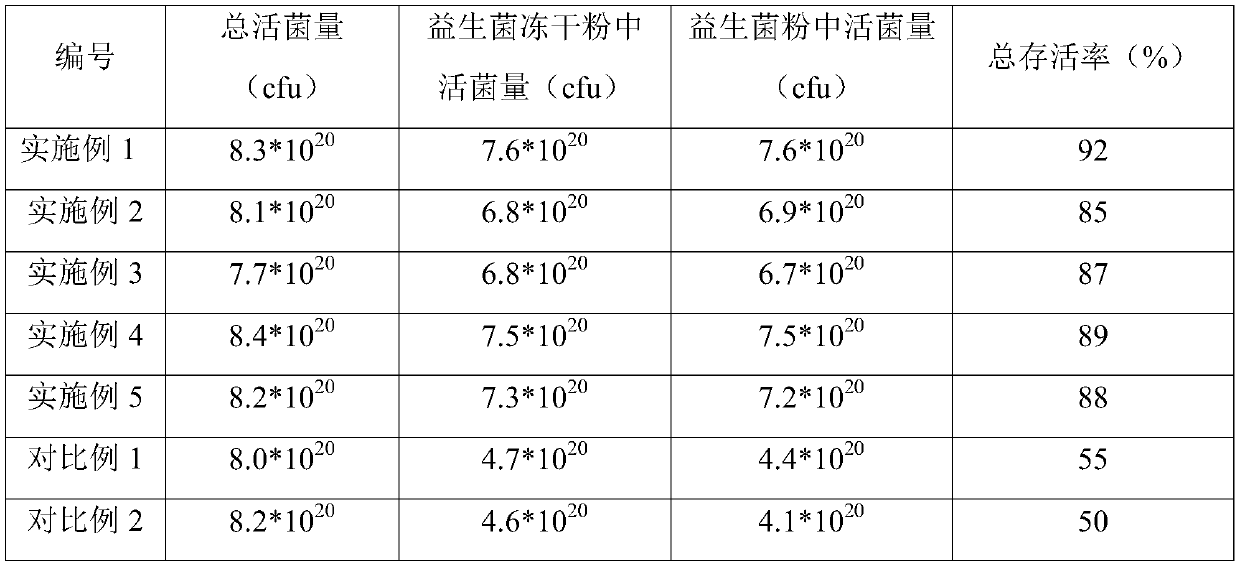

Probiotic powder and production method thereof

PendingCN110720638AGuaranteed survival rateThe freeze-drying process went smoothlyFood preservationFood ingredient functionsBiotechnologyFreeze-drying

The invention discloses probiotics powder and a production method thereof. The probiotics powder is prepared from, by mass, 17-55 parts of probiotics freeze-dried powder, 2-15 parts of zinc gluconateand 3-23 parts of water-soluble dietary fibers; wherein the probiotic freeze-dried powder comprises probiotics, silicon dioxide aerogel and a freeze-drying protective agent. According to the preparation method, the silicon dioxide hydrogel is used as a base material of a probiotic culture medium, the probiotics can be uniformly distributed and grow in a porous structure of the hydrogel, the product uniformity is high, a three-dimensional network structure of the silicon dioxide hydrogel can play a role in protecting probiotics thalli in the freeze drying process, and the survival rate of the probiotics is increased.

Owner:SHENZHEN DUOWEISHENG HEALTH FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com