Fruit vacuum freeze drying method

A vacuum freeze-drying and fruit technology, which is applied in the fields of fruit and vegetable preservation, food preservation, food science, etc., can solve the problems of infection, large loss of nutrient components, and large loss of nutrient components, so as to prevent material dissolution and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

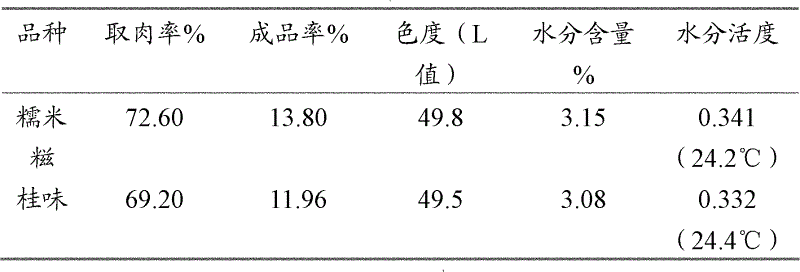

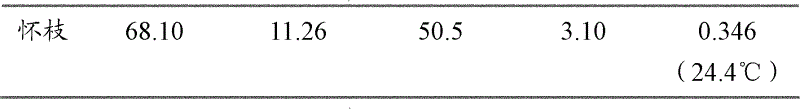

Examples

Embodiment 1

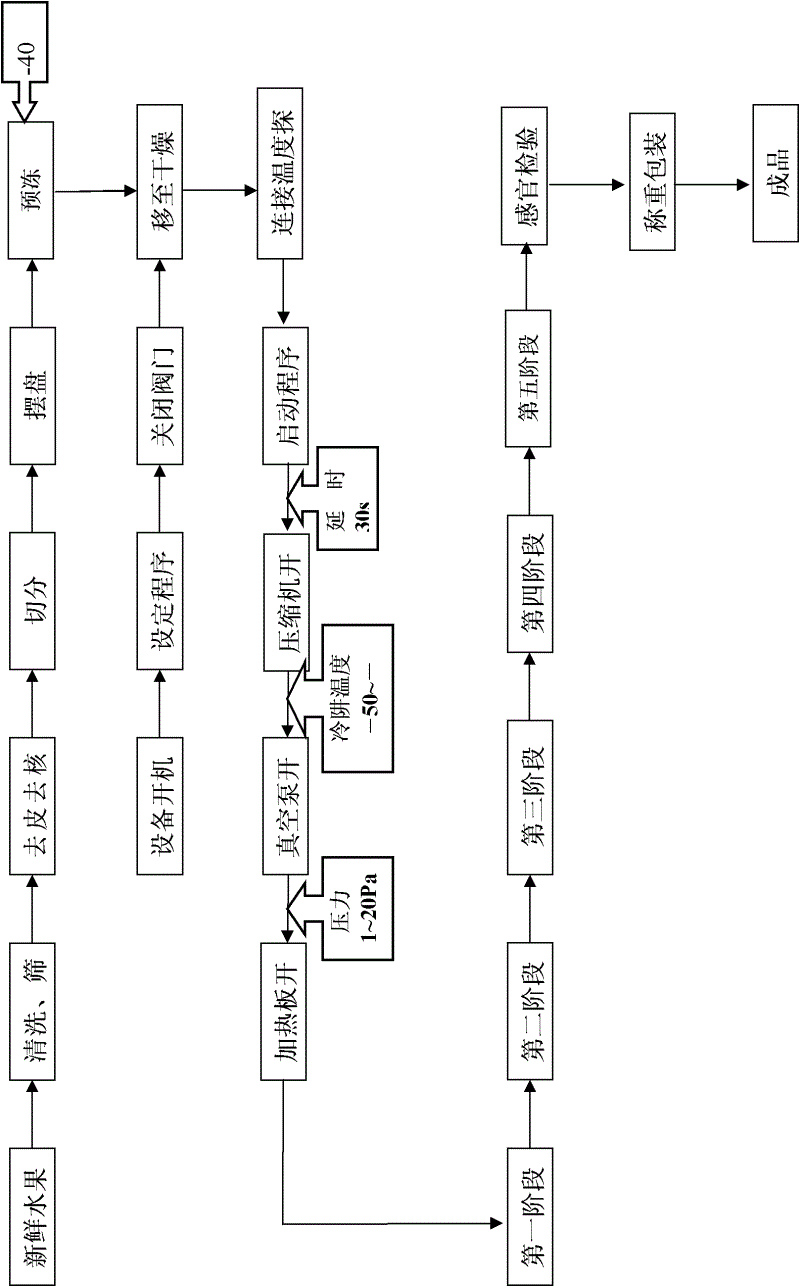

[0077] The fruit vacuum freeze-drying method of the embodiment of the present invention comprises the following steps:

[0078] (1) Raw material pretreatment

[0079] Take fresh cinnamon-flavored lychees, wash them with clean water, peel and remove the core, cut them into two halves evenly, and lay them flat on the tray with the concave side facing up;

[0080] (2) Pre-freezing

[0081] Place the tray in a pre-freezer at -40°C for quick freezing, and then pre-freeze for 3 hours after the core temperature of the lychee pulp reaches -25°C;

[0082] (3) Move into the drying room

[0083] Move the pre-frozen lychee pulp to the drying room, place the tray containing lychees on the drying rack in the drying room from top to bottom, and connect the center and upper and lower temperature probes;

[0084] (4) Set boot program

[0085] Set the opening condition of the vacuum pump as the cold trap temperature -51°C, and the heating opening condition of the heating plate as the drying...

Embodiment 2

[0096] The embodiment of the present invention dragon fruit vacuum freeze-drying method, comprises the steps:

[0097] (1) Raw material pretreatment

[0098] Take fresh red-fleshed dragon fruit, rinse the skin with clean water, peel off the skin, and cut into 10mm thick fruit slices, spread them on the tray to avoid overlap of fruit slices;

[0099] (2) Pre-freezing

[0100] Place the tray in a pre-freezer at -40°C for quick freezing. When the temperature of the center of the pitaya pulp reaches -20°C, keep it for 2 hours;

[0101] (3) Move into the drying room

[0102] Move the pre-frozen dragon fruit pulp to the drying room, place the tray containing the pulp on the shelf in the drying room from top to bottom, and connect the center and upper and lower temperature probes;

[0103] (4) Set boot program

[0104] Set the opening condition of the vacuum pump to be that the temperature of the cold trap is -55°C, and the opening condition of the heating plate heating is that t...

Embodiment 3

[0113] The embodiment of the present invention guava or carambola vacuum freeze-drying method comprises the steps:

[0114] (1) Raw material pretreatment

[0115] Take fresh ripe guava (carambola), rinse the skin with clean water, cut the guava into 12mm thick fruit slices (carambola is cut into 10mm thick five-pointed star), and spread it on the tray to avoid overlapping of fruit slices;

[0116] (2) Pre-freezing

[0117] Place the tray in a pre-freezer at -40°C for quick freezing, and when the core temperature of the pulp reaches -20°C, keep it for 2 hours;

[0118] (3) Move into the drying room

[0119] Move the pre-frozen pulp to the drying room, place the tray containing the pulp on the shelf in the drying room from top to bottom, and connect the center and upper and lower temperature probes;

[0120] (4) Set boot program

[0121] Set the opening condition of the vacuum pump as the temperature of the cold trap at -53°C, and the opening condition of the heating plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com