Probiotic powder and production method thereof

A probiotic freeze-dried powder, probiotic technology, applied in the directions of Lactobacillus, Bifidobacterium, bacteria used in food preparation, etc., can solve the problems of probiotic inactivation, uneven distribution of bacteria, etc., to improve production efficiency , The effect of shortening freeze-drying time and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

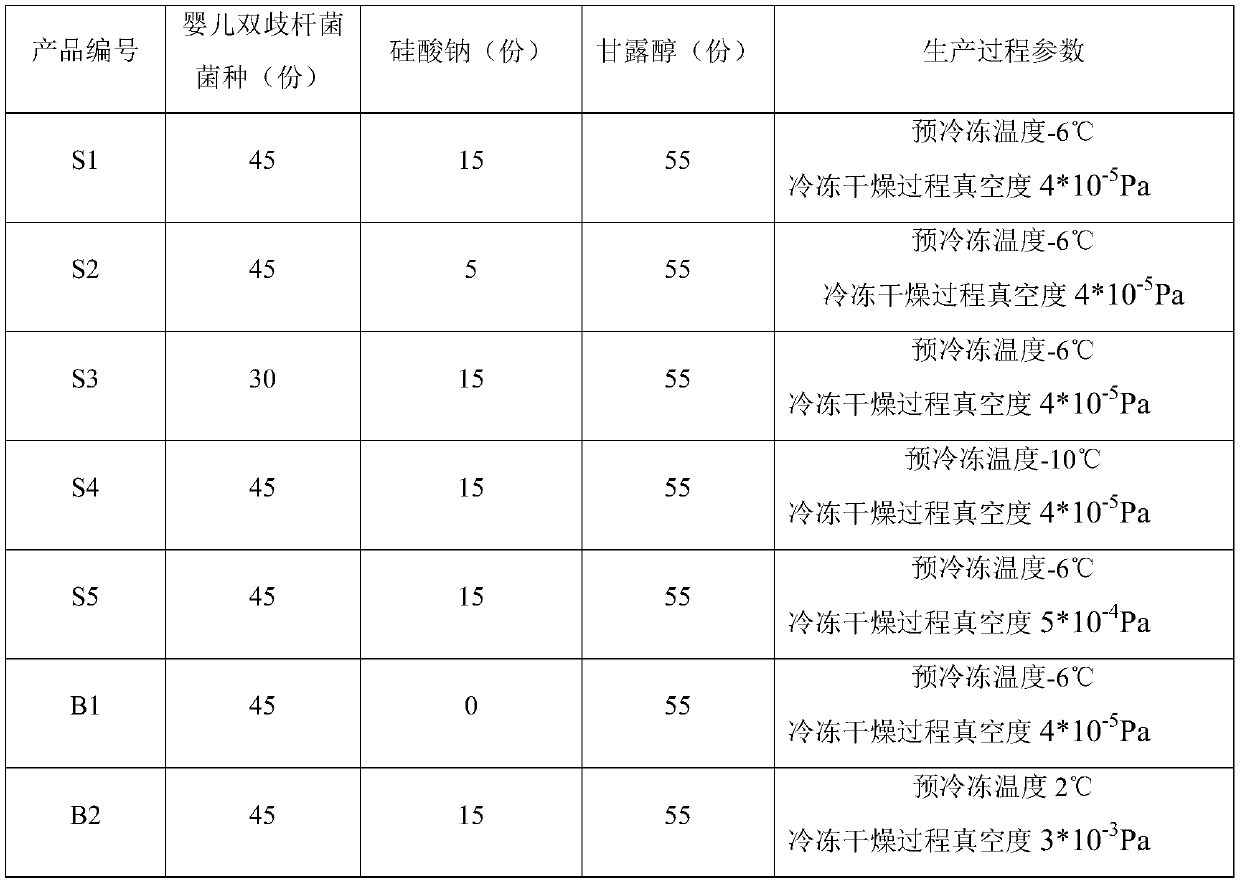

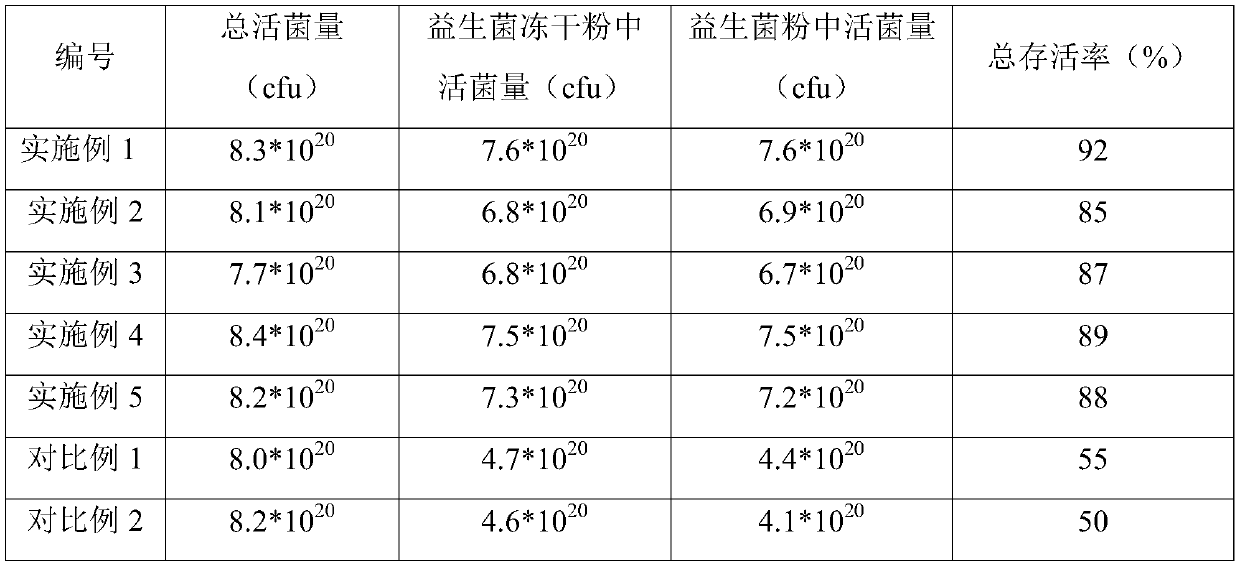

Examples

Embodiment 1

[0040] 1. Preparation of probiotic freeze-dried powder

[0041] (1) Add 15 parts of sodium silicate to 100 parts of distilled water, stir and mix evenly, then drop in dilute hydrochloric acid with a mass concentration of 8% until the pH of the solution is 4, reflux for 3 hours, and then add ammonia water with a mass concentration of 20% , adjust the pH of the solution to 8, and obtain a silica hydrogel after aging for 5 hours.

[0042] (2) Take out and mash the silica hydrogel, soak it in distilled water, and replace it with new distilled water during this period, remove the incompletely reacted acid or alkali, and other impurities in the system until the pH of the whole system is 7 , and filtered to obtain pure silica hydrogel.

[0043] (3) Perform high-pressure steam sterilization on the filtered silica hydrogel under the following conditions: steam pressure 150KPa, steam temperature 120°C, and maintain for 15 minutes. Then disperse the sterilized silica hydrogel evenly in...

Embodiment 2

[0050] 1. Preparation of probiotic freeze-dried powder

[0051] (1) Add 5 parts of sodium silicate to 100 parts of distilled water, stir and mix evenly, then drop in dilute hydrochloric acid with a mass concentration of 8% until the pH of the solution is 4, reflux for 3 hours, and then add ammonia water with a mass concentration of 20% , adjust the pH of the solution to 8, and obtain a silica hydrogel after aging for 5 hours.

[0052] (2) Take out and mash the silica hydrogel, soak it in distilled water, and replace it with new distilled water during this period, remove the incompletely reacted acid or alkali, and other impurities in the system until the pH of the whole system is 7 , and filtered to obtain pure silica hydrogel.

[0053] (3) Perform high-pressure steam sterilization on the filtered silica hydrogel under the following conditions: steam pressure 150KPa, steam temperature 120°C, and maintain for 15 minutes. Then disperse the sterilized silica hydrogel evenly in ...

Embodiment 3

[0060] 1. Preparation of probiotic freeze-dried powder

[0061] (1) Add 15 parts of sodium silicate to 100 parts of distilled water, stir and mix evenly, then drop in dilute hydrochloric acid with a mass concentration of 8% until the pH of the solution is 4, reflux for 3 hours, and then add ammonia water with a mass concentration of 20% , adjust the pH of the solution to 8, and obtain a silica hydrogel after aging for 5 hours.

[0062] (2) Take out and mash the silica hydrogel, soak it in distilled water, and replace it with new distilled water during this period, remove the incompletely reacted acid or alkali, and other impurities in the system until the pH of the whole system is 7 , and filtered to obtain pure silica hydrogel.

[0063] (3) Perform high-pressure steam sterilization on the filtered silica hydrogel under the following conditions: steam pressure 150KPa, steam temperature 120°C, and maintain for 15 minutes. Then disperse the sterilized silica hydrogel evenly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com