High earth-rockfill dam deformation monitoring fiber sensing technology and system

An earth-rock dam and optical fiber technology, applied in the field of distributed optical fiber sensing monitoring system, can solve the problems of easy lateral sliding, few measuring points, weak overall information of the dam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

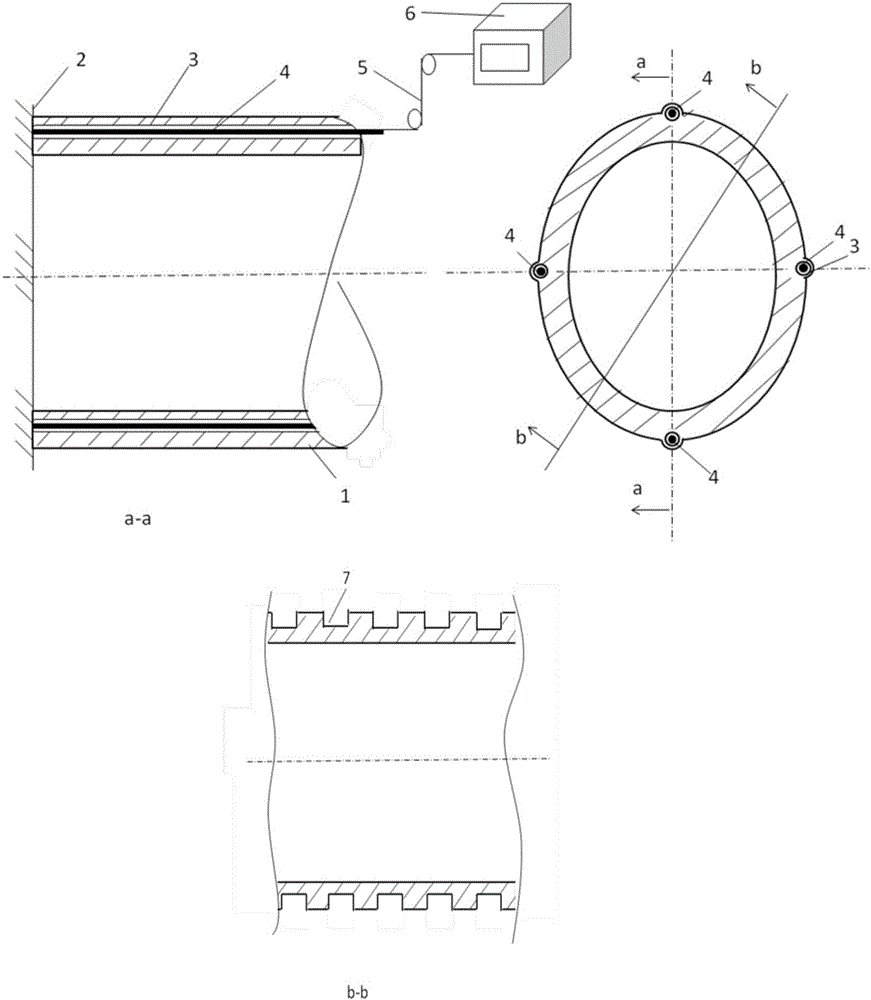

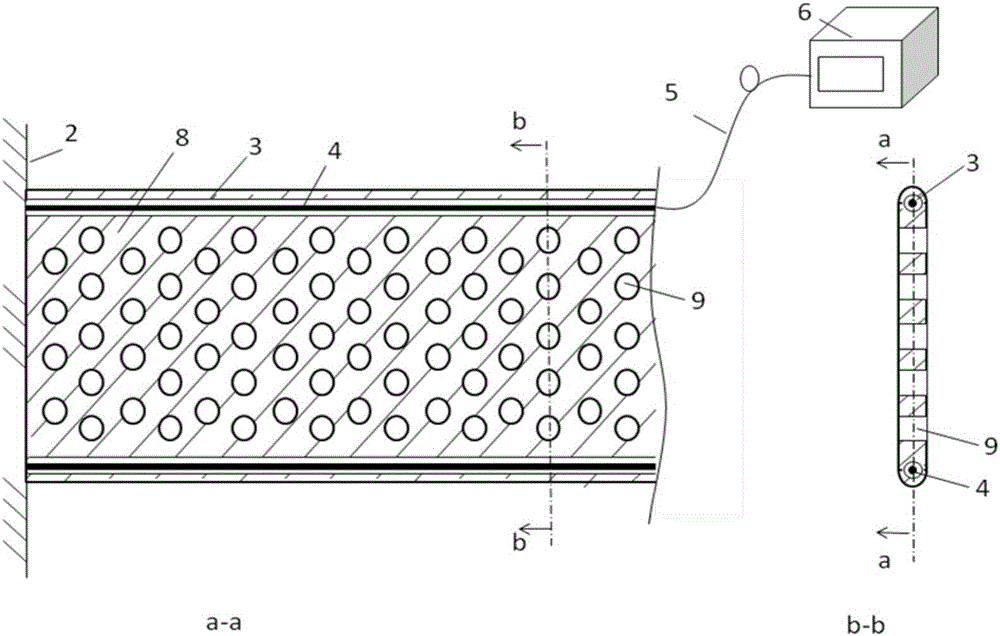

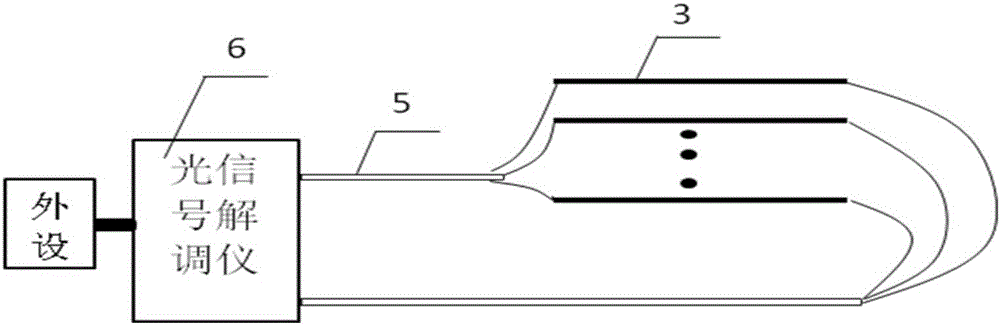

[0075](1) Embedding of optical fiber packages: The packages are buried by the trench method, along the designed line of the optical fiber monitoring line, and the embedding grooves are excavated in the filling layer, such as Figure 8 , the packaging board is put into the groove, and the total station is used for control and measurement to ensure accurate positioning and leveling, to ensure the plumbness of the vertical board and the levelness of the horizontal board; the installation of the joints between the board sections must be firm and firm. Fiber-optic air blowing operation to test the smoothness and airtightness of the microtubes of the monitoring board; the backfill of the dam material in the buried groove shall be manually compacted until it is 50cm higher than the top of the groove, and then two layers of 50cm thick shall be laid on it, and the maximum particle size in the rockfill area shall be 300mm , vibrating roller static pressure, on which to resume normal oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com