Freezing and drying integrated vacuum freezing and drying machine

A vacuum freeze-drying and freeze-drying technology, which is used in local stirring dryers, dryers for static materials, dryers, etc., can solve the problem of low heat exchange effect of refrigerant returning to liquid heater and increased operating load of refrigeration compressor units. , increase the production cost and volume of the equipment, and achieve the effects of shortening the vacuum drying time, reducing production costs and use costs, and reasonable equipment configuration and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

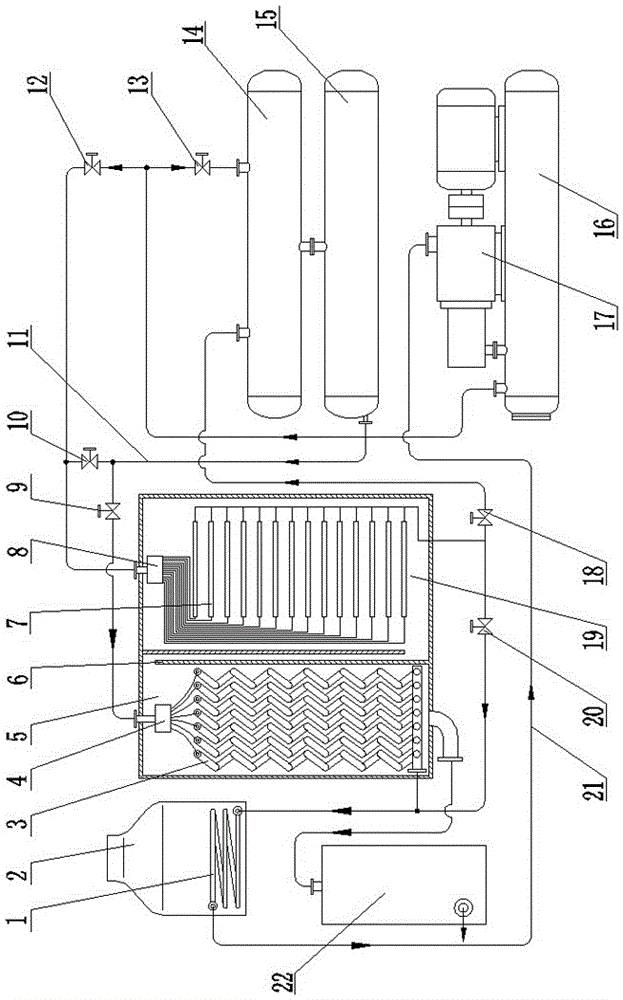

[0015] Such as figure 1 As shown, among them: 1-coil, 2-cooling tower, 3-heat exchanger, 4-water catcher distributor, 5-water catcher, 6-water catcher partition, 7-refrigerated evaporation plate, 8 -Distributor for freeze-drying evaporation chamber, 9-valve Ⅰ, 10-valve Ⅱ, 11-refrigeration pipeline, 12-valve Ⅲ, 13-valve Ⅳ, 14-condenser, 15-liquid storage tank, 16-oil separator , 17-refrigeration compressor, 18-valve Ⅴ, 19-freeze-drying evaporation chamber, 20-valve Ⅵ, 21-refrigeration compressor low-pressure stage suction pipeline, 22-vacuum pump.

[0016] Freeze-drying: Now place the material to be freeze-dried on the freezing evaporation plate 7, and then close the door of the freeze-drying evaporation chamber 19 to seal the freeze-drying evaporation chamber. Through the control of the electrical control cabinet, start the cooling tower 2 and the refrigeration compressor 17, then open the valve IV13, valve II10, and valve VI20, and close the valve V18, valve I9, and valve II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com