Heat pump system based on regenerative cycle and throttling element control method

A heat pump system and regenerative cycle technology, applied in heat pumps, superheaters, refrigerators, etc., can solve problems such as clogging of low-pressure throttling elements, improve exhaust temperature, relieve suction low pressure and throttling elements congestion problems, The effect of improving low temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The heat recovery cycle used in the refrigeration industry is generally used in the refrigeration cycle, not in the heating cycle. In the refrigeration cycle, its main functions are: 1. Make the liquid refrigerant fully supercooled to prevent flash gas from appearing in the liquid refrigerant pipeline, and ensure that the refrigerant before entering the throttle valve is in liquid state; 2. Improve Compressor suction temperature to prevent evaporator frosting, condensation and compressor liquid hammer phenomenon.

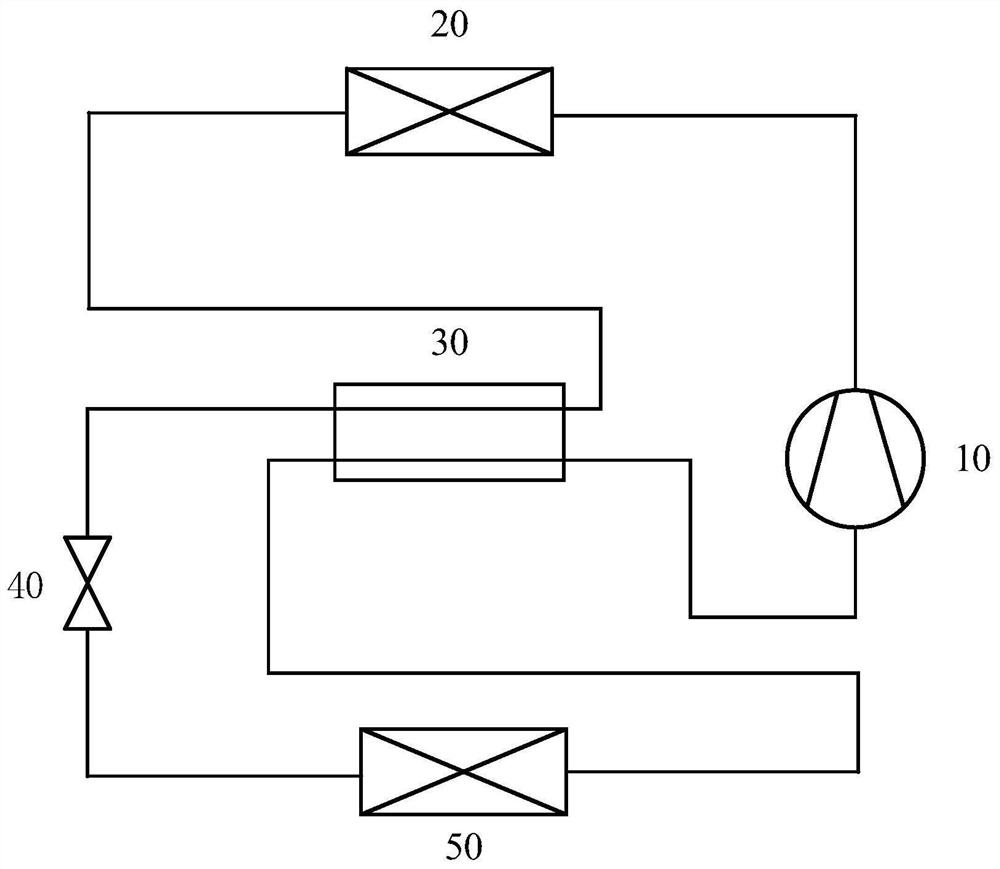

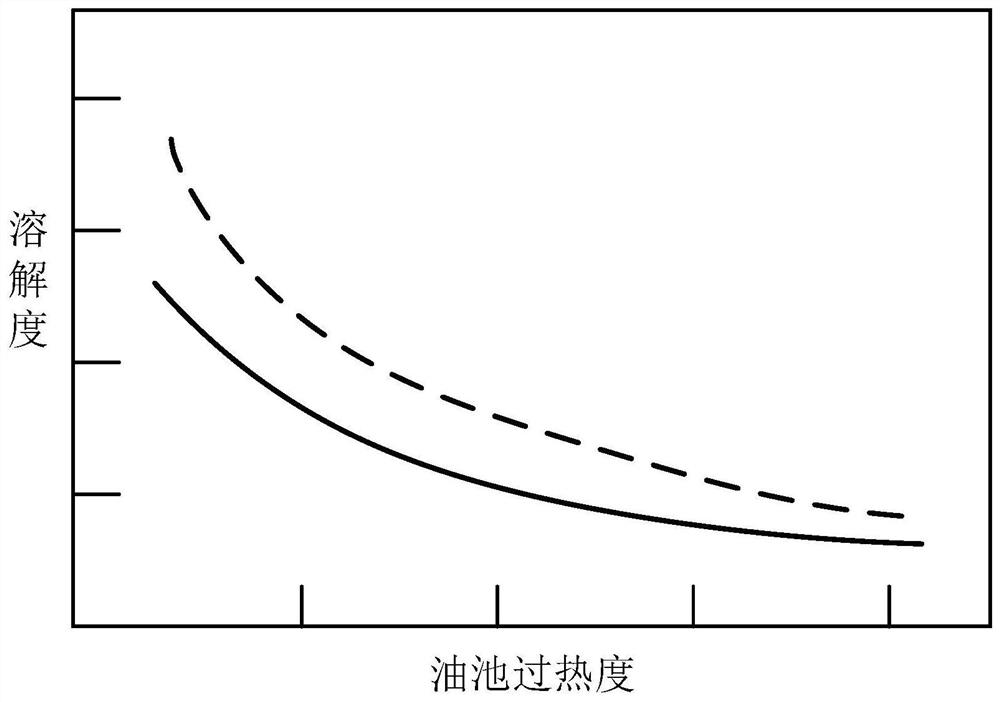

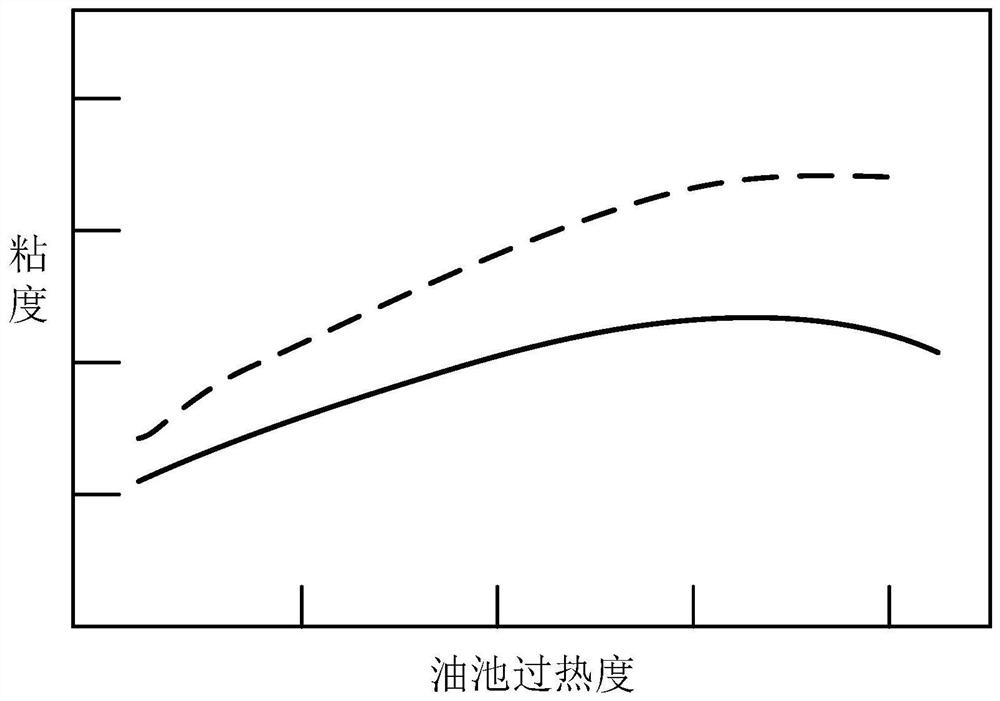

[0033] The present invention proposes a heat pump system based on a heat recovery cycle and a control method for a throttling element. The system uses the heat recovery cycle in the heating cycle, and utilizes the surplus caused by the temperature difference between the high temperature at the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com