Cascade compression refrigeration system and refrigeration equipment with same

A compression refrigeration, cascading technology, applied in refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problems of condensation at the suction port of low-temperature compressors, reduced refrigeration efficiency, low suction temperature, etc., to improve operation performance, increase the suction temperature, and improve the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

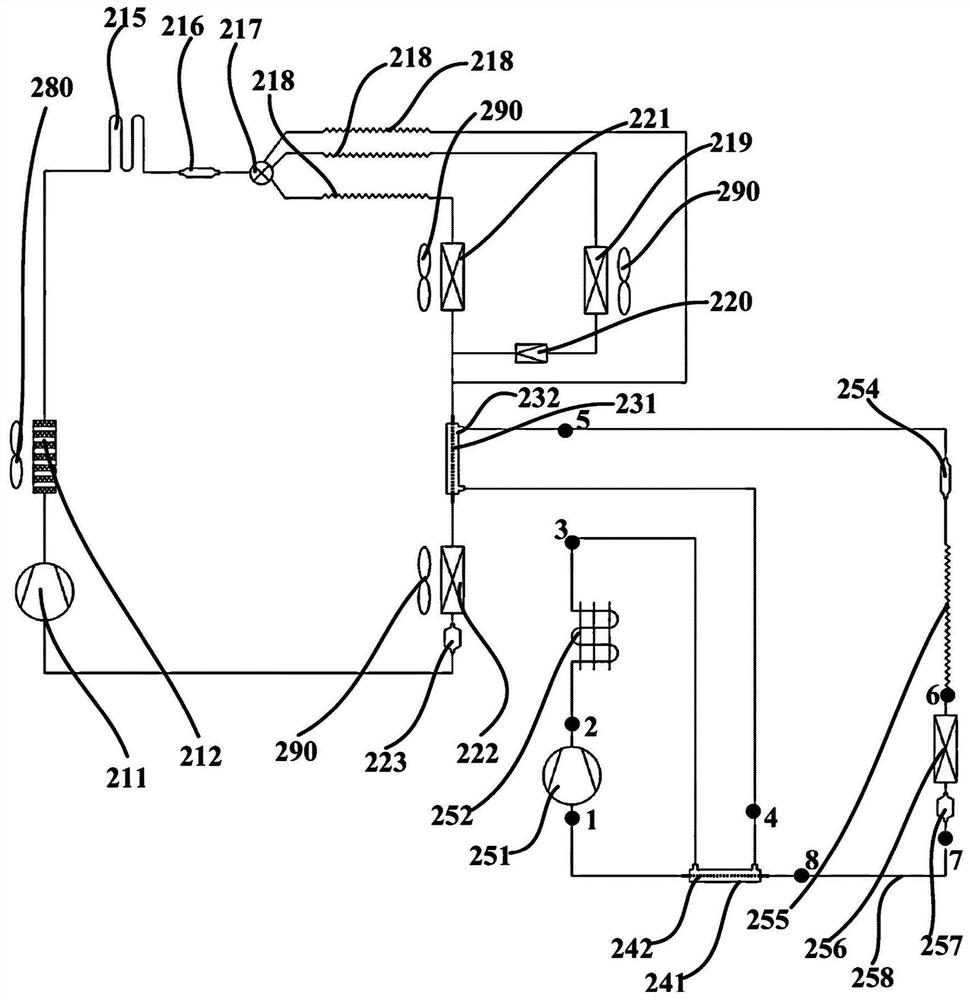

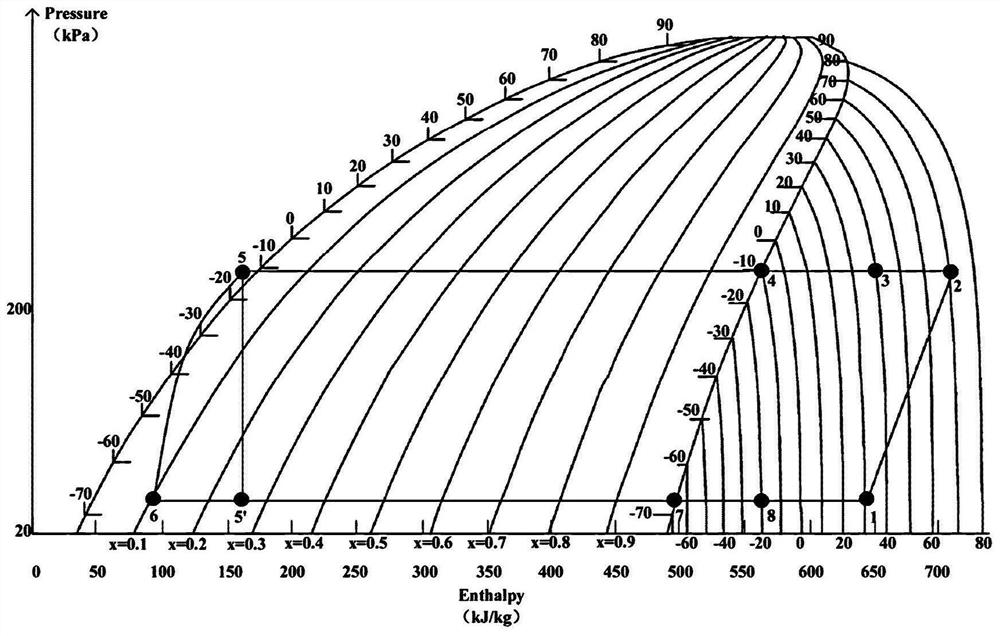

[0030] figure 1 is a schematic diagram of a refrigeration device 10 with a cascade compression refrigeration system according to one embodiment of the present invention.

[0031] The refrigerating device 10 may be a small domestic refrigerating device for storing foodstuffs, medicines, or other items, for example, it may be a refrigerator or a freezer.

[0032] Although the cascade compression refrigeration system has been involved in large-scale refrigeration equipment, however, due to the excessive operating noise and high energy consumption of the existing cascade compression refrigeration system, the cascade compression refrigeration system in the prior art The system has been unable to be applied to household small refrigeration equipment.

[0033] The cascade compression refrigeration system of this embodiment is especially suitable for small domestic refrigeration equipment 10, such as a refrigerator.

[0034] The refrigeration device 10 in this embodiment takes a ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com