Fosaprepitant dimeglumine freeze-dried powder and preparation method thereof

A technology of fosaprepitant dimeglumine and freeze-dried powder, which is applied in the field of medicine and can solve problems such as insufficient treatment, insufficient attention, and overtreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1, the preparation of fosaprepitant dimeglumine freeze-dried powder, in 1000 pieces.

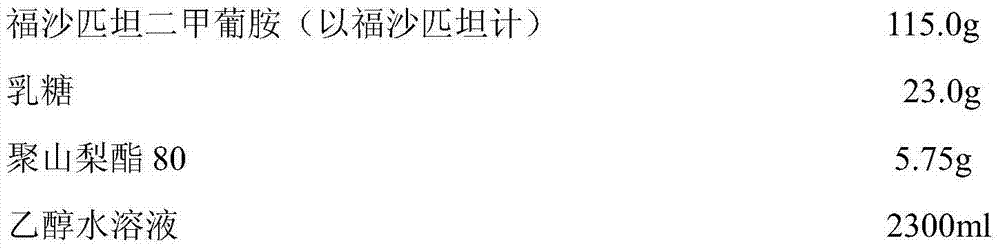

[0018] 1. Prescription

[0019]

[0020] 2. Preparation process

[0021] a): adding fosaprepitant dimeglumine, lactose, and polysorbate into an aqueous ethanol solution to dissolve, and stirring evenly;

[0022] b): above-mentioned solution adjusts PH value with sodium hydroxide solution, adds 0.05% gac, stirs 15-30min; Filter gac, medicinal liquid passes through 0.45um and 0.22um microporous membrane filtration again, detects intermediate content, according to each The bottle contains 115mg of fosaprepitant dimeglumine for filling.

[0023] c): Filling is completed, half stoppered, put into a freeze-drying box, pre-frozen at -45°C, and kept warm for 1.5 hours. Slowly raise the temperature to 0°C, then raise the temperature to 30°C, and keep it warm for 2h. After the freeze-drying process is over, it is out of the box.

example 2

[0024] Example two, the preparation of fosaprepitant dimeglumine freeze-dried powder, in 1000 pieces.

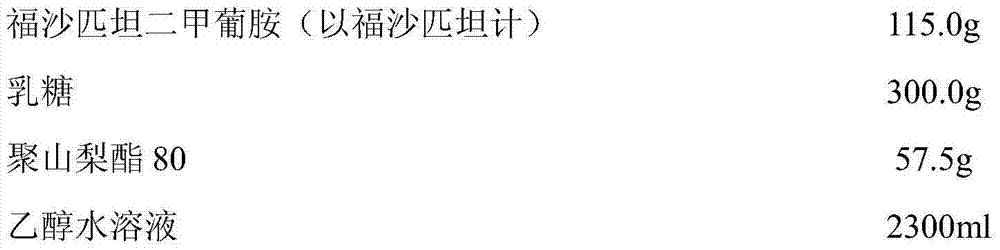

[0025] 1. Prescription

[0026]

[0027] 2. Preparation process

[0028] a): adding fosaprepitant dimeglumine, lactose, and polysorbate into an aqueous ethanol solution to dissolve, and stirring evenly;

[0029] b): above-mentioned solution adjusts PH value with sodium hydroxide solution, adds 0.05% gac, stirs 15-30min; Filter gac, medicinal liquid passes through 0.45um and 0.22um microporous membrane filtration again, detects intermediate content, according to each The bottle contains 115mg of fosaprepitant dimeglumine for filling.

[0030] c): Filling is completed, half stoppered, put into a freeze-drying box, pre-frozen at -45°C, and kept warm for 1.5 hours. Slowly raise the temperature to 0°C, then raise the temperature to 30°C, and keep it warm for 2h. After the freeze-drying process is over, it is out of the box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com