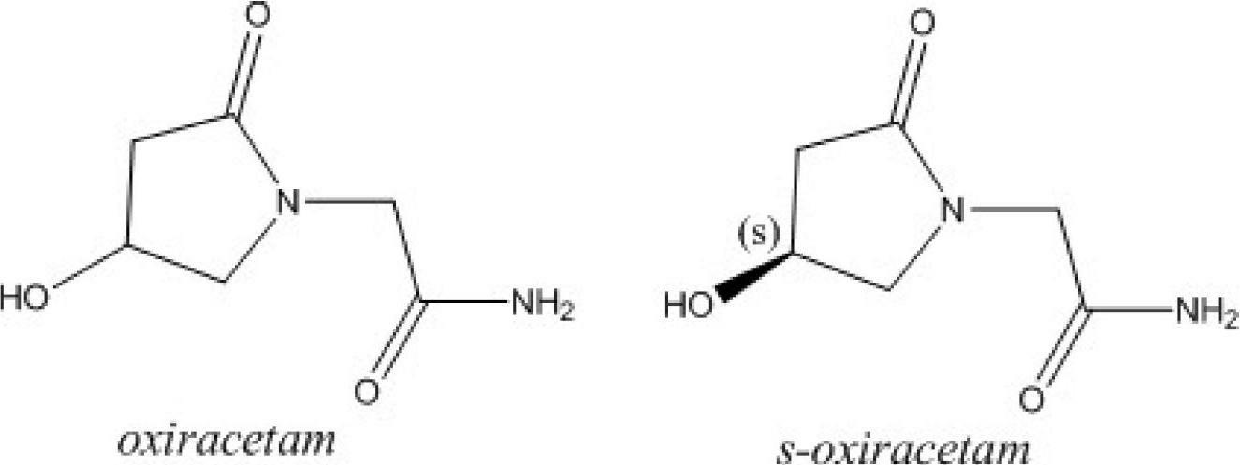

Freeze-dried powder injection of L-oxiracetam and process for preparing freeze-dried powder injection

A freeze-dried powder for injection and freeze-drying technology is applied in the field of freeze-dried powder injection of levo-oxiracetam and its preparation technology, which can solve the problems of decreased solubility, high solution viscosity, long freeze-drying time and the like, and achieves improved solubility, Increased stability and rapid reconstitution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

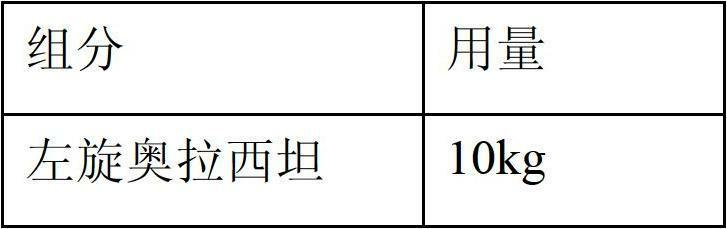

[0031] Embodiment 1 prescription 1 and preparation technology

[0032] Prescription 1:

[0033]

[0034]

[0035] Preparation Process:

[0036] 1) Mix 10Kg levoxiracetam and 0.8Kg PEG4000 evenly and disperse them in 35L of hot water at 45-50°C. After the dissolution is complete, add 8kg sorbitol and 0.6kg sodium dihydrogen phosphate to dissolve completely.

[0037] 2) Adjust the pH of the solution to 4.0 with 0.2mol / L disodium hydrogen phosphate solution,

[0038] 3) Add water to full volume, stir for 10 minutes,

[0039] 4) Decarburize 0.1% w / v activated carbon for 15 minutes, filter through a 1 μm titanium rod filter to remove carbon, and filter through a 0.45 μm cartridge filter;

[0040] 5) Sampling after filtration with a 0.22 μm terminal filter for intermediate inspection;

[0041] 6) After passing the inspection, it is potted and sealed in a vial;

[0042] 7) Freeze-drying:

[0043] First put the subpackaged medicines on the inner partition of the freeze-dry...

Embodiment 2

[0046] Embodiment 2 prescription 2 and preparation technology

[0047] Prescription 2:

[0048]

[0049]

[0050] Preparation Process:

[0051] 1) Mix 10kg of levoxiracetam and 0.6kg of PEG6000 evenly and disperse in 40L of hot water at 45-50℃. After the dissolution is complete, add 8k of mannitol and 0.4kg of sodium dihydrogen phosphate to dissolve completely.

[0052] 2) Adjust the pH of the solution to 5.0 with 0.2mol / L disodium hydrogen phosphate solution,

[0053] 3) Add water to full volume, stir for 10 minutes,

[0054] 4) Decarburize 0.1% w / v activated carbon for 15 minutes, filter through a 1 μm titanium rod filter to remove carbon, and filter through a 0.45 μm cartridge filter;

[0055] 5) Sampling after filtration with a 0.22 μm terminal filter for intermediate inspection;

[0056] 6) After passing the inspection, it is potted and sealed in a vial;

[0057] 7) Freeze-drying:

[0058] First put the subpackaged medicines on the inner partition of the freeze-...

Embodiment 3

[0061] Embodiment 3 prescription 3 and preparation technology

[0062] Prescription 3:

[0063]

[0064] Preparation Process:

[0065] 1) Mix 10kg of levoxiracetam and 0.8kg of PEG6000 evenly and disperse in 40L of hot water at 45-50°C. After the dissolution is complete, add 10kg of lactose and 0.5kg of sodium dihydrogen phosphate to dissolve completely.

[0066] 2) Adjust the pH of the solution to 5.5 with 0.2mol / L disodium hydrogen phosphate solution,

[0067] 3) Add water to full volume, stir for 10 minutes,

[0068] 4) Decarburize 0.1% w / v activated carbon for 15 minutes, filter through a 1 μm titanium rod filter to remove carbon, and filter through a 0.45 μm cartridge filter;

[0069] 5) Sampling after filtration with a 0.22 μm terminal filter for intermediate inspection;

[0070] 6) After passing the inspection, it is potted and sealed in a vial;

[0071] 7) Freeze-drying:

[0072] First put the subpackaged medicines on the inner partition of the freeze-drying b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com