Microwave continuous freeze-drying system

A technology of freeze-drying and microwave, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of high utilization rate, high cost and long freeze-drying cycle of vacuum water catcher, and achieve the elimination of microwave vacuum electric field Breakdown phenomenon, efficiency improvement, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

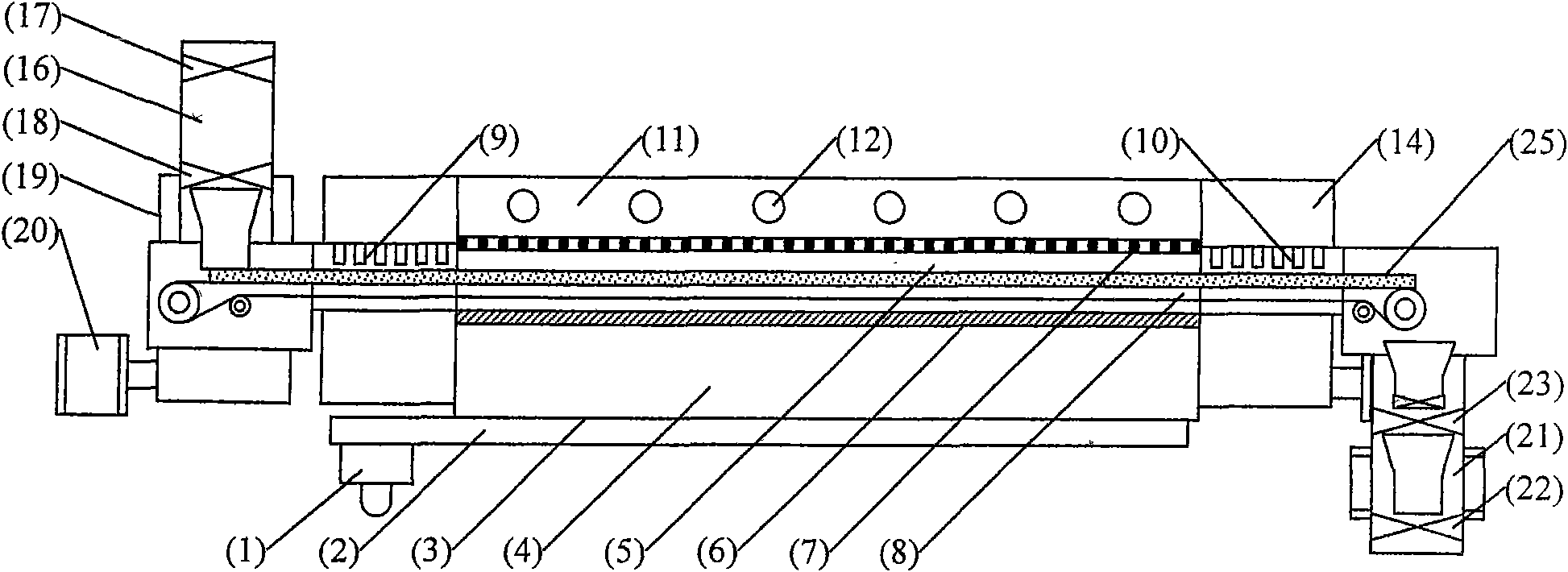

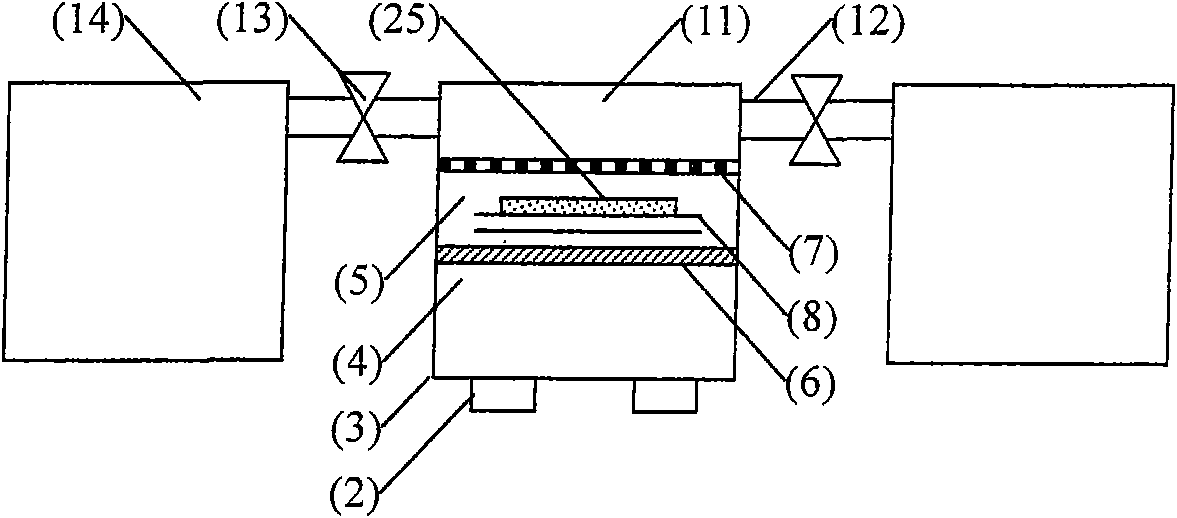

[0046] A microwave continuous freeze-drying system, comprising a microwave vacuum freeze-drying device, a vacuum water catcher, a vacuum feeding device, and a vacuum discharging device, wherein the microwave vacuum freeze-drying device includes a microwave generator 1, a microwave antenna 2, an atmospheric pressure microwave Cavity 4, vacuum microwave cavity 5, vacuum partition 6, porous air-permeable microwave shielding plate 7, low-loss conveyor belt 8, front-end vacuum microwave suppressor 9, rear-end vacuum microwave suppressor 10, characterized in that: freeze-dried in microwave vacuum The device is provided with a composite freeze-drying chamber 3 composed of an atmospheric microwave chamber 4 and a vacuum microwave chamber 5, and is separated by a microwave-permeable vacuum partition 6 between the atmospheric pressure microwave chamber 4 and the vacuum microwave chamber 5. The vacuum microwave cavity 5 is connected to the steam channel 11 of the vacuum water catcher, and...

Embodiment 2

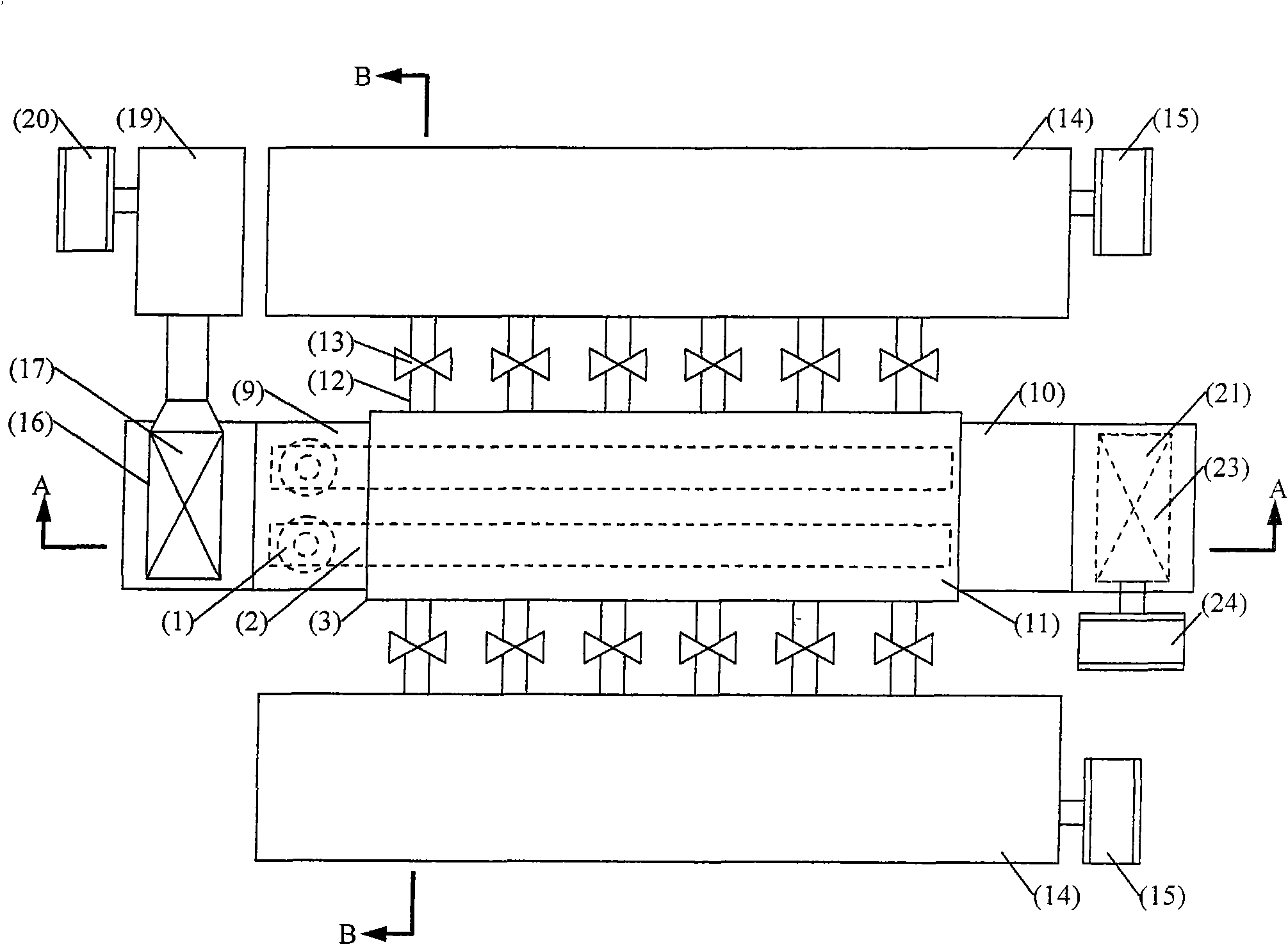

[0059] Such as figure 1 , 2 , 3 form a set of microwave continuous freeze-drying system. It consists of a vacuum feeding device for vertical feeding, a microwave vacuum freeze-drying device, a vacuum discharging device, and a vacuum water-catching device.

[0060] The specific design of each part of this embodiment is as follows:

[0061] 1. Microwave generator 1 adopts four 915MHz, 75kW microwave sources, with a total power of 300kW;

[0062] 2. Microwave energy is fed into the atmospheric pressure microwave cavity 4 by the microwave antenna 2;

[0063] 3. The distance between the atmospheric pressure microwave cavity 4 and the vacuum partition 6 is 500 mm to make the microwave field more uniform;

[0064] 4. The low-loss conveyor belt 8 is made of PTFE-coated glass fiber belt, which can avoid the falling of materials and is suitable for processing small or granular materials;

[0065] 5. The steam channel 11 of the vacuum water catcher is located above the vacuum microw...

Embodiment 3

[0080] Such as figure 1 , 2 , 3, but change the vacuum feeding device to such as Figure 7 , 8 shown. The system consists of a vacuum feeding device for horizontal feeding, a microwave vacuum freeze-drying device, a vacuum discharging device, and a vacuum water trapping device.

[0081] The specific design of each part of this embodiment is as follows:

[0082] 1. Microwave generator 1 uses two 2450MHz, 30kW microwave sources, with a total power of 60kW;

[0083] 2. The distance between the atmospheric pressure microwave cavity 4 and the vacuum partition 6 is 200mm to make the microwave field more uniform;

[0084] 3. The cold trap 14 of the vacuum water catching device has a water catching capacity greater than or equal to 120kg / h

[0085] 4. The horizontal feeding vacuum chamber is adopted, which can conveniently input large bulk materials;

[0086] 5. Others are the same as in Example 1.

[0087] The system formed in this embodiment can be used to process a cube-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com