Aerogel micro powder and preparation method thereof

An airgel and gel technology, applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., to achieve the effects of reduced energy consumption, low density, and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] An aspect of the embodiments of the present invention provides a method for preparing aerogel powder, which includes:

[0037] Provide a hydrogel, crush the hydrogel, and then disperse it in water to form a gel fluid or gel dispersion;

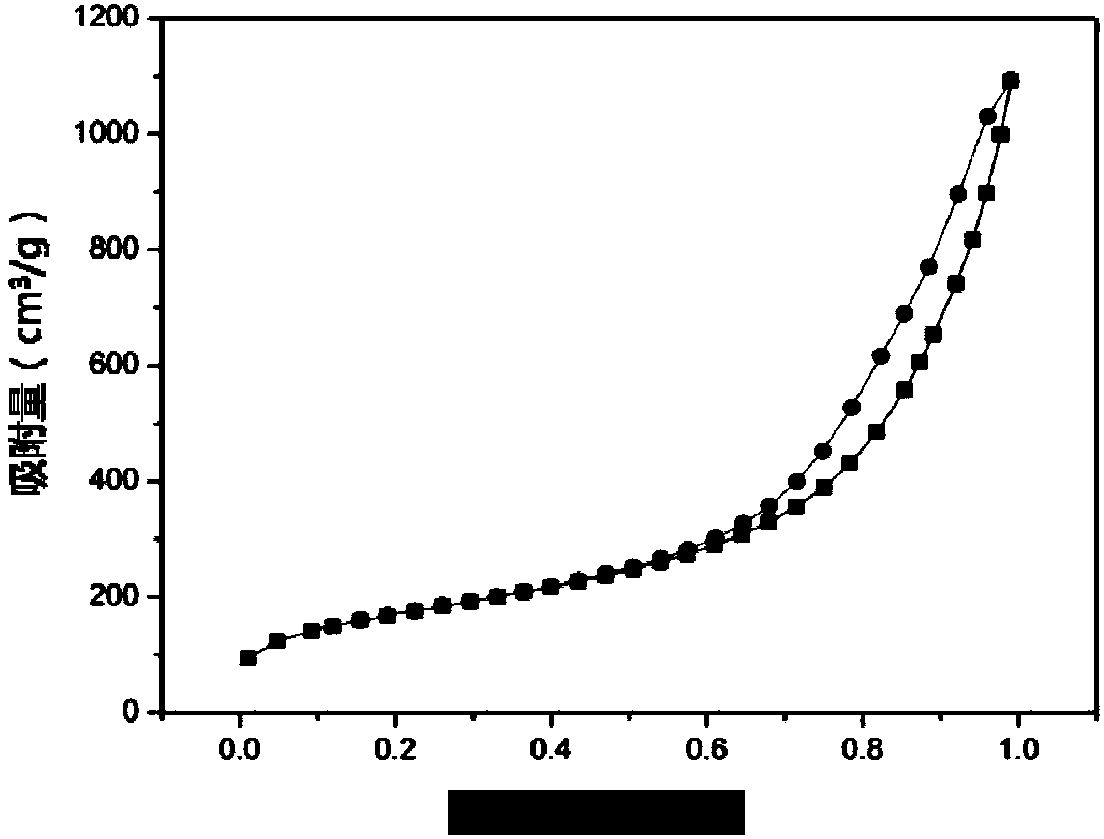

[0038] Using an atomizing device to atomize the gel fluid or gel dispersion to form gel droplets, and collect the gel droplets in a low-temperature container to obtain gel frozen particles;

[0039] The frozen gel particles are freeze-dried to obtain aerogel powder.

[0040] As one of the preferred embodiments, the hydrogel includes any of non-metal oxide hydrogels, metal oxide hydrogels, carbon-based hydrogels, polymer hydrogels and composite hydrogels One or a combination of two or more, but not limited to this. These hydrogels can be obtained commercially, or can be prepared in a suitable manner known in the industry. For example, you can refer to the literature: Functional Materials, 2009, 1(40): 151-153, Journal of Non-Crystalline Solids2...

Embodiment 1

[0170] (1) Preparation of silica hydrogel: mix 1 mole of water glass (wherein the content of silica is 26-28% by weight) and deionized water in a volume ratio of 1:2, then add 0.4 mole of water Dilute acid solution (10 -3 mol / L), stir evenly and let it stand overnight. After the gel is formed, it is then aged for 24 hours and replaced with deionized water 4 times to obtain the silica hydrogel.

[0171] (2) Atomizing the silica hydrogel: crushing the silica hydrogel in step (1) with strong mechanical stirring to obtain a silica hydrogel fluid for use. The silica hydrogel fluid was injected into the nozzle of the atomizer at a rate of 30 mL / h, and the droplets with a particle size of about 20 μm were obtained after atomization. The mist droplets are sprayed into the low-temperature container, and the temperature of the low-temperature container is as low as -60°C. After the mist droplets fall, they will freeze and freeze rapidly to obtain frozen particles.

[0172] (3) Freeze drying...

Embodiment 2

[0176] (1) Preparation of graphene hydrogel: Disperse graphene oxide in deionized water by ultrasound, centrifuge at 1500r / min for 40min, collect the supernatant, and then centrifuge the supernatant at 8000r / min for 4h for concentration , Collect the lower dispersion system to obtain a graphene oxide aqueous solution with a concentration of 8 mg / mL, and then add 1% vitamin C to reduce to obtain graphene hydrogel.

[0177] (2) Atomizing the graphene hydrogel: After breaking the above-mentioned gel, it is injected into the nozzle of the atomizer at a rate of 30 mL / h, and atomized to obtain droplets with a particle size of about 80 μm. The mist droplets are sprayed into the low-temperature container, and the temperature of the low-temperature container is as low as -80°C. After the droplets fall, they will freeze and freeze quickly to obtain frozen particles.

[0178] (3) Freeze drying graphene hydrogel frozen particles: the collected graphene hydrogel frozen particles are quickly tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com