Preparation method for filling ultralow-resistivity conductive paste with high-purity nano material

A technology of conductive paste and low resistivity, applied in conductive coatings, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as explosion, affecting conductivity, and increased copper resistivity, and reduce costs , improve the purity, reduce the effect of resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

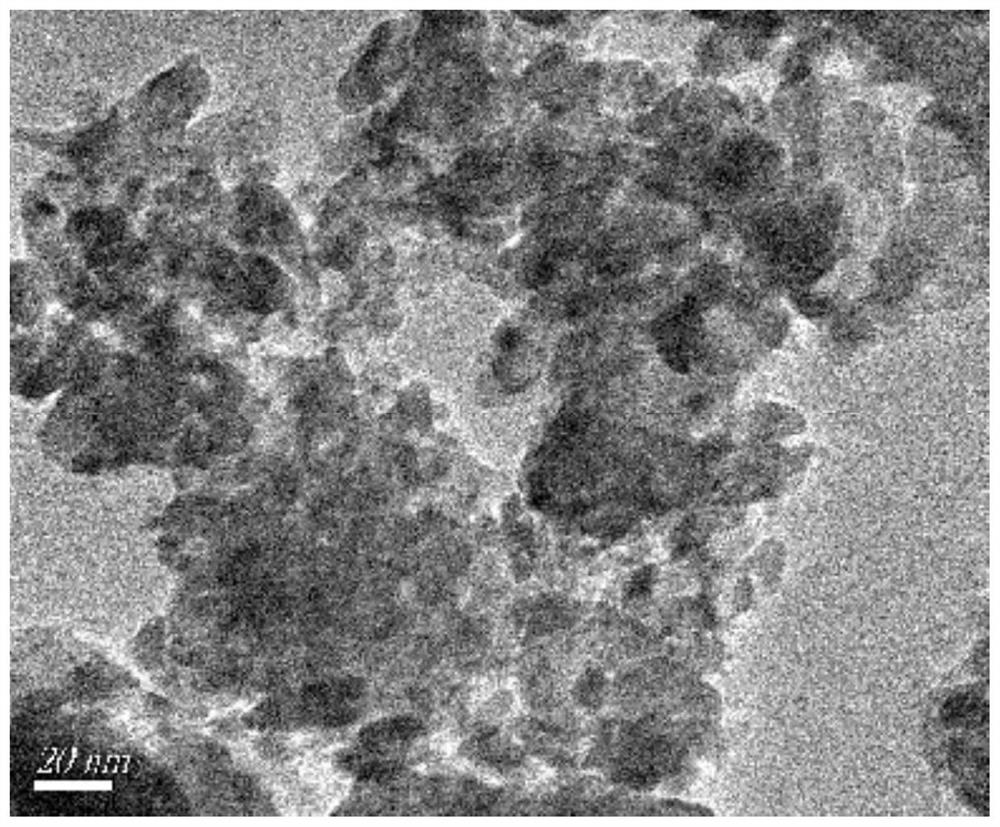

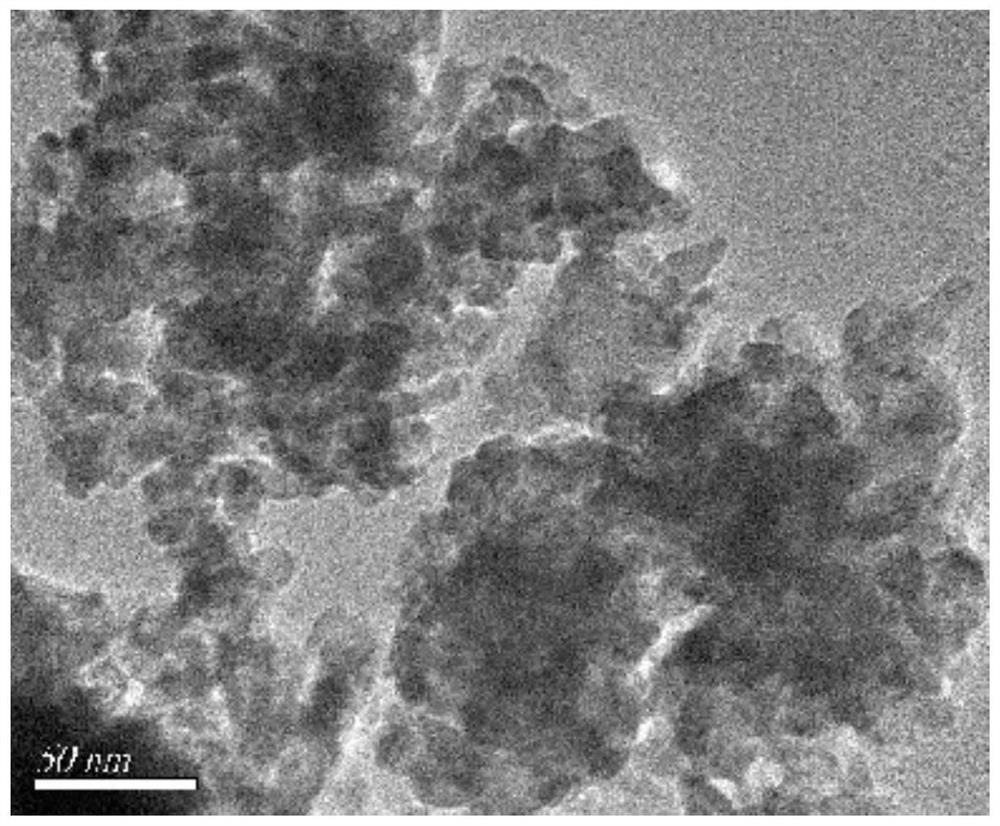

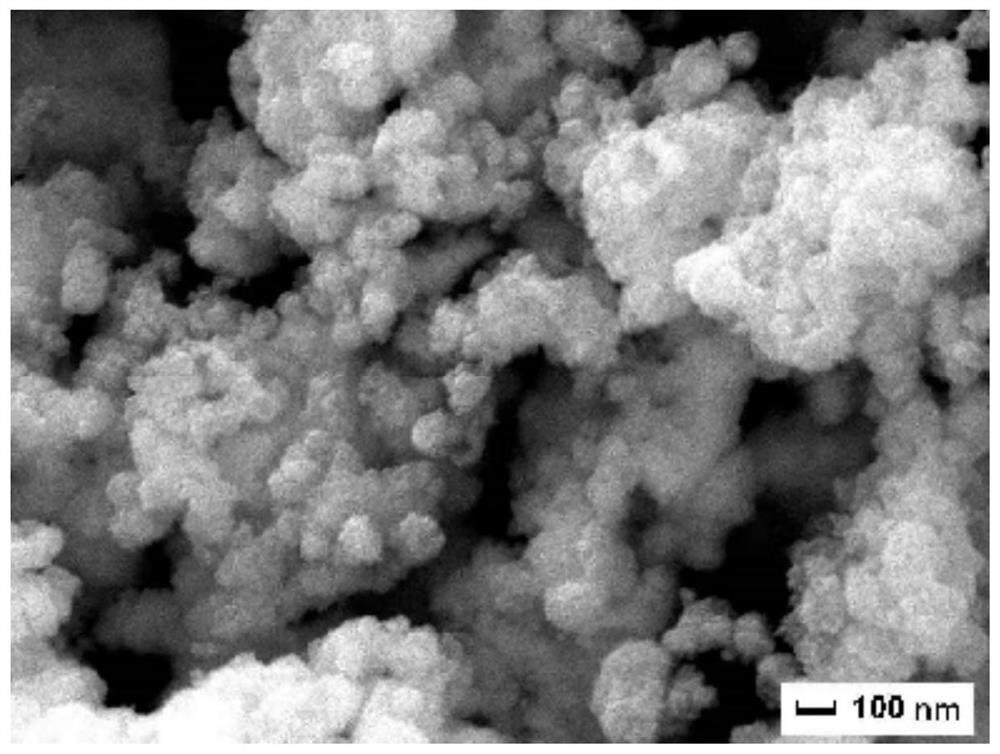

Image

Examples

Embodiment

[0034] The preparation method of the ultra-low resistivity conductive paste filled with high-purity nanomaterials in this embodiment includes the following steps:

[0035] (1) Prepare a mixed aqueous solution with a copper nitrate content of 10% and a silver nitrate content of 0.001% (the mixed aqueous solution contains 10 g of copper nitrate, 1 mg of silver nitrate, and 89.999 g of water) and start stirring, then add oxalic acid powder while stirring, and detect the change in pH value , when the pH value is lower than 1.16, add 1% ammonia water to adjust the pH value in the range of 1.16 to 4.16, when the cumulative amount of oxalic acid powder added is 4.9g, stop adding, continue to stir, react for 40 minutes, filter to obtain oxalic acid A crystal mixture of copper and silver oxalate, the crystal size of copper oxalate and silver oxalate is about 1mm;

[0036] (2) The crystalline mixture of copper oxalate and silver oxalate obtained in step (1) is packed into a roasting fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com