High-dispersivity fluorescent whitening agent and preparation method thereof

A fluorescent whitening agent, high dispersibility technology, applied in the field of fluorescent whitening agents, can solve the problem of not pointing out the specific index of powder product dispersibility, not disclosing the preparation method of highly dispersible particle fluorescent whitening agent composition, and not providing to issues such as decentralization requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

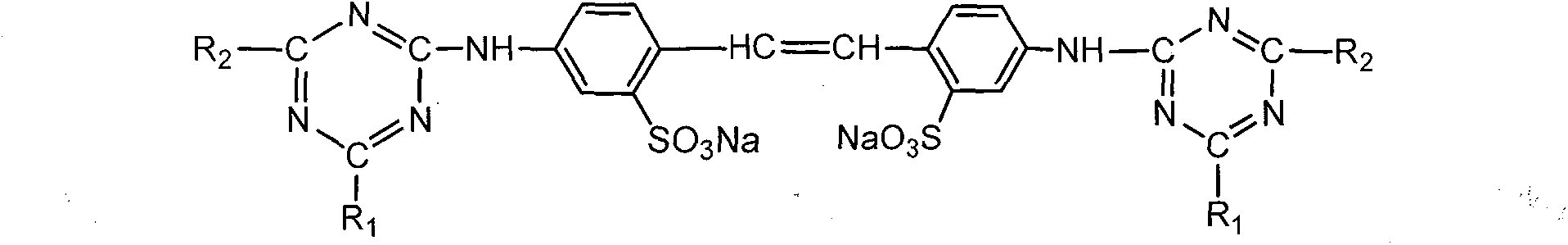

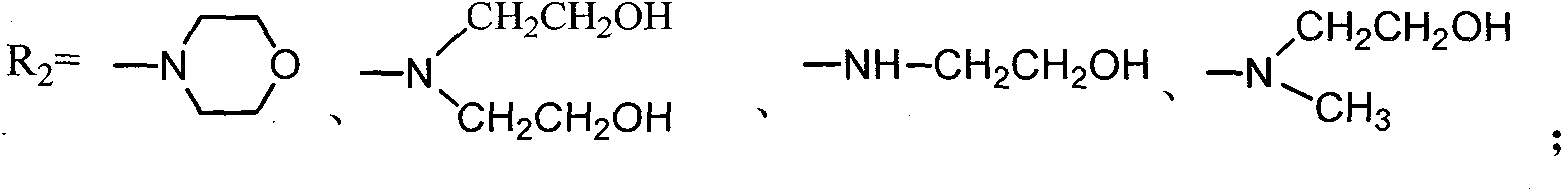

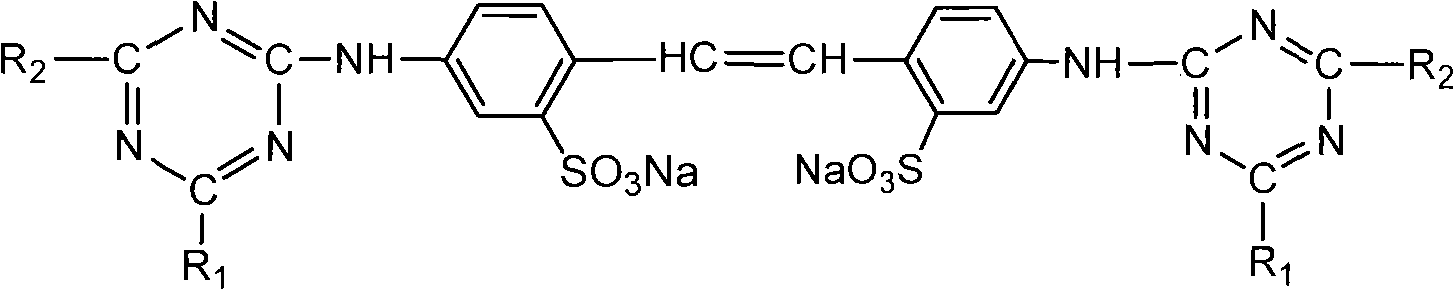

Embodiment 1

[0025] 12.8kg fluorescent whitening agent 4,4'-bis[(4-anilino-6-morpholinyl-1,3,5-triazin-2-yl)amino]stilbene-2,2'- Disulfonic acid disodium salt dry powder, 2.6kg sodium methylene bis-naphthalene sulfonate, 3kg sodium sulfate, 1kg sodium carbonate are added to 45.6kg water, beating and dispersing until the particle fineness is ≤50 microns, and then sending the slurry into the grinding medium Grind in a 5L sand mill with a filling rate of 80%. Grind three times (56 minutes in total) to reach the particle size of the original whitening agent ≤ 5 microns. The slurry after grinding has good fluidity and is sprayed Dry to obtain a bulk density of 536kg m -3 granular fluorescent whitening agent.

[0026] The product has good fluidity and is easy to use, and its dispersibility in detergent reaches 64.1% in 2 minutes and 88.5% in 10 minutes.

Embodiment 2

[0028] 34.4kg fluorescent whitening agent 4,4'-bis[(4-anilino-6-morpholinyl-1,3,5-triazin-2-yl)amino]stilbene-2,2'- Disulfonic acid disodium salt filter cake (solid content 48.6%), 1.7kg sodium methylene bis-naphthalene sulfonate, 2kg sodium sulfate, 1kg sodium carbonate are added to 18.8kg water, beating and dispersing until particle fineness≤50 microns , add the slurry to a 5L sand mill with a grinding medium filling rate of about 80% for grinding, and grind three times (total time-consuming 48min) to reach the particle size of the original whitening agent ≤ 5 microns, the slurry after grinding Good fluidity, it is spray-dried to obtain a bulk density of 553kg m -3 granular fluorescent whitening agent. The dispersibility in detergent reaches 70.2% in 2 minutes; 92.5% in 10 minutes.

Embodiment 3

[0030] 36.2kg fluorescent whitening agent 4,4'-bis[(4-anilino-6-methoxy-1,3,5-triazin-2-yl)amino]stilbene-2,2'- Disulfonic acid disodium salt filter cake (solid content 45.7%), 2kg sodium lignosulfonate, 1.6kg sodium chloride, 1kg potassium hydroxide join in 21.4kg water, after beating is dispersed to particle fineness≤50 microns, Add the slurry to a 5L sand mill with a grinding medium filling rate of about 80% for grinding, and grind three times (62 minutes in total) to achieve the particle size of the original whitening agent ≤ 5 microns, and the slurry after grinding Good fluidity, it is spray-dried to obtain a bulk density of 502kg m -3 granular fluorescent whitening agent. The dispersibility in detergent reaches 63.6% in 2 minutes; 87.5% in 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com