A compound wet-grinding concrete waste slag functional additive and its application

A technology of concrete waste slag and functional additives, which is applied in the field of functional additives for functional building materials, can solve the problems of limited grinding aid effect of dispersants, inability to guarantee adaptability, and reduced activity, so as to improve early strength and work performance, and engineering application High value, no irritating smell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

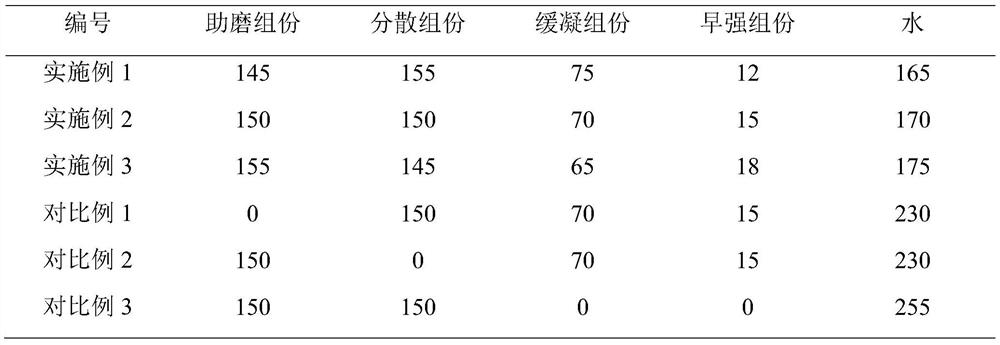

Embodiment 1-3 and comparative example 1-3

[0023] A comparative wet grinding concrete waste residue function auxiliaries, components and components of each component Reference Table 1, specific preparation steps are: according to the mass fraction, sequentially, the coefficient, dispersion component, and success Components, early strength components, and water are mixed in the reaction kettle.

[0024] Its co-equivalent of diecetanolamine, triethanolamine composition is a mass ratio of 1: 2;

[0025] Its dispersion component is a single-ended bisoxy polyethylene glycol-isophorone diisocyanate copolymer having a mass ratio of 1: 1, a single-end dihydroxy polyethylene glycol-isophorone diisocyanate copolymer, the above polymerization The amount of molecular molecular molecular weight is 3000 ~ 5000.

[0026] Its loose component is a molase;

[0027] Its early strength components are calcium nitrate and sodium nitrate compositions of 1: 2.

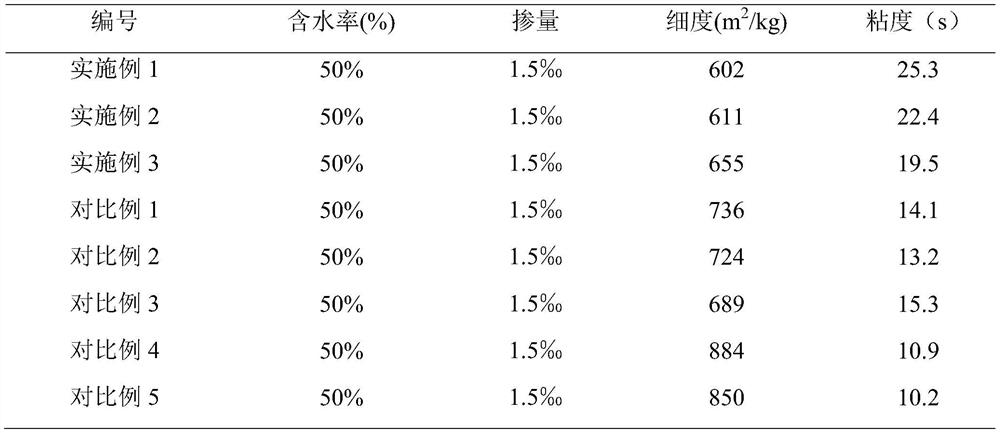

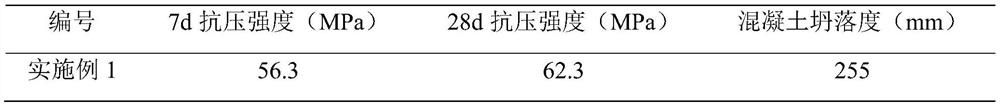

[0028] The specific performance test results of the resulting function auxiliaries ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com