Solid-liquid mixing equipment and method

A solid-liquid mixing and equipment technology, which is applied in the direction of mixing methods, liquid and solid mixing, mixers, etc., can solve the problems of low mixing efficiency, easy dead angle, uneven crushing, etc., achieve high mixing and crushing contact area, improve Particle fineness, the effect of prolonging the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

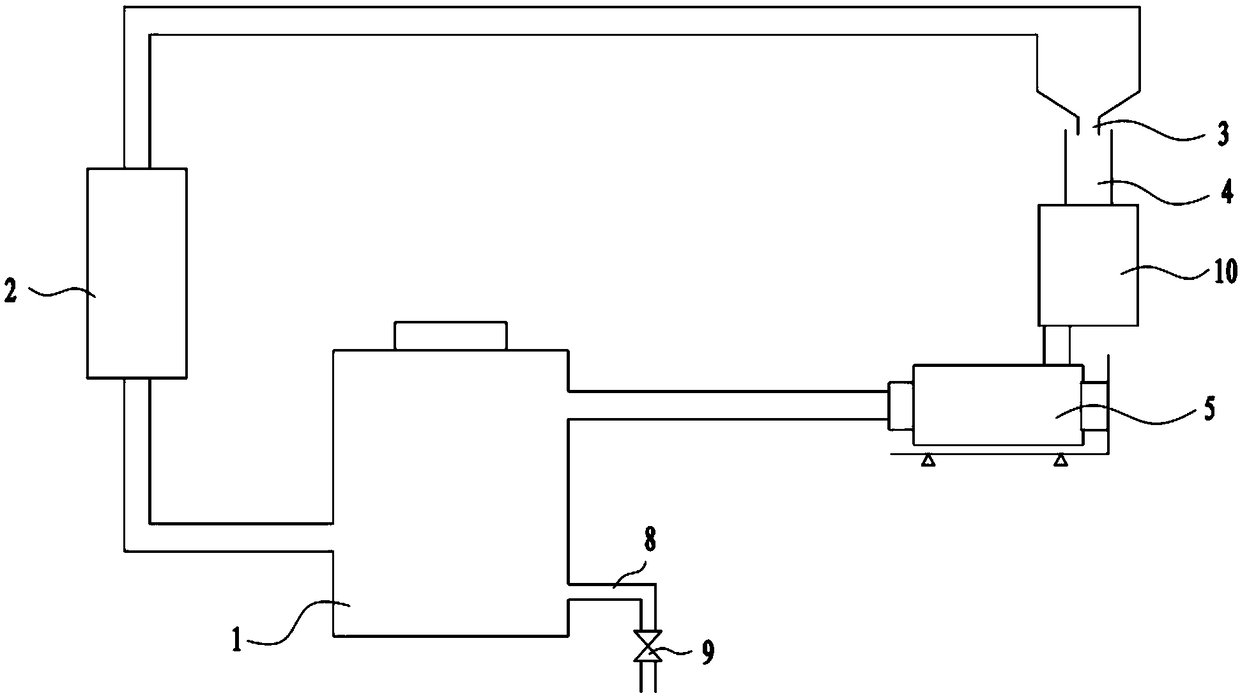

[0031] Such as figure 1 As shown, this embodiment provides a solid-liquid mixing device, which mainly includes a storage tank 1 , a first pump body 2 , a nozzle 3 , a material receiving pipe 4 , a second pump body 10 and a sand mill 5 . Wherein the storage tank 1, the first pump body 2, the nozzle 3, the material receiving pipe 4, the second pump body 10 and the sand mill can be regarded as being connected end to end in sequence. Specifically, the bottom of the storage tank 1 is connected to the feed port of the first pump body 2, and the discharge port of the first pump body 2 is connected to the tail of the nozzle 3. One end of the pipe 4 is located in the ejection direction of the feed liquid of the nozzle 3. In this embodiment, the opening of one end of the feed pipe 4 is located below the nozzle 3, and the other end of the feed pipe 4 is connected to the feed port of the second pump body 10. The outlet of the second pump body 10 is connected to the inlet of the sand mill...

Embodiment 2

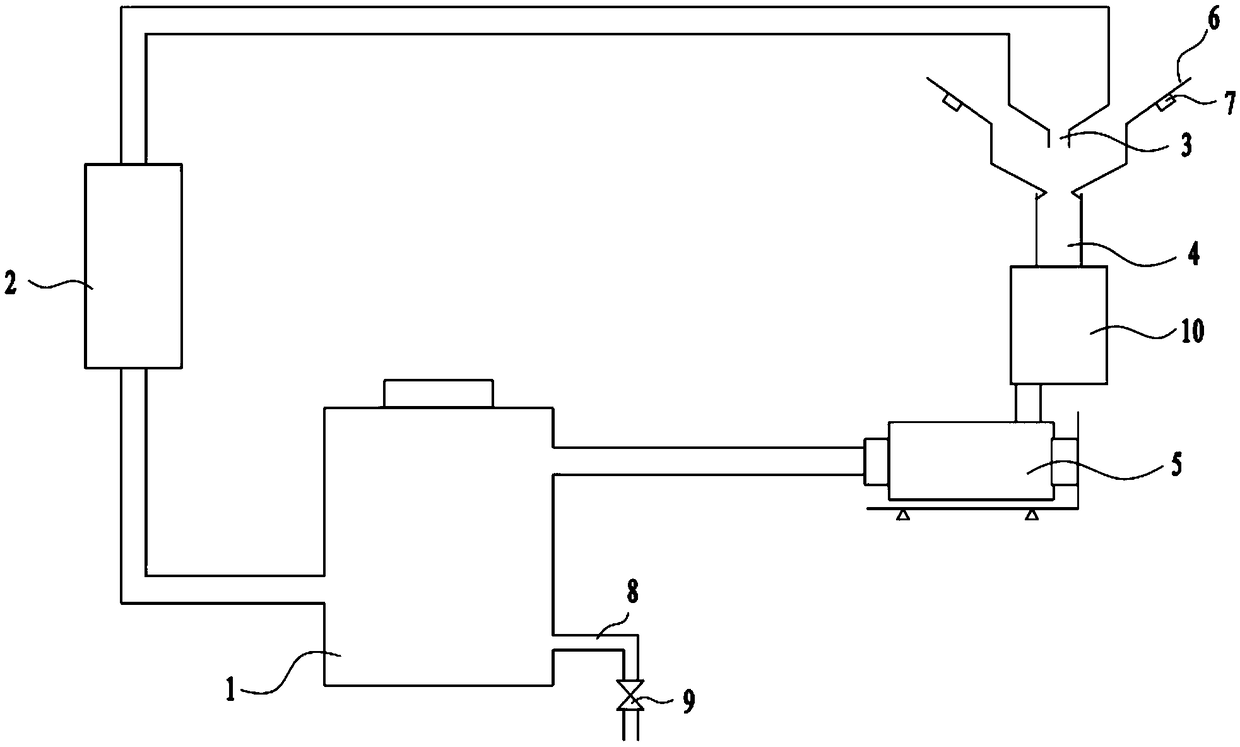

[0035] For the sake of simplicity, only describe the difference between embodiment 2 and embodiment 1, and its difference is:

[0036] The solid-liquid mixing equipment in this embodiment also includes a discharge device 6 , which is funnel-shaped and connected to one end of the material receiving pipe 4 . The funnel-shaped feeding device 6 can increase the holding capacity of the material and prevent the material from leaking out. The discharging device 6 is used to add solid materials in batches, thereby increasing the quality of the materials in the storage tank 1 . After setting the feeding device 6, the quality of the feed liquid in the whole equipment can be increased without stopping the machine, thereby improving the mixing efficiency. An electromagnetic vibrator 7 is arranged on the top of the funnel-shaped feeding device 6 . The electromagnetic vibrator 7 can vibrate the side wall of the discharge device 6, so that the material can fall into the material receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com