Compound functional aid for wet grinding of concrete waste residues and application thereof

A technology for concrete waste residues and functional additives, which is applied in the field of functional building materials as functional additives, can solve the problems of limited grinding-aiding effect of dispersants, inability to guarantee adaptability, and increased viscosity, so as to improve the early strength and working performance, engineering The effect of high application value and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-3

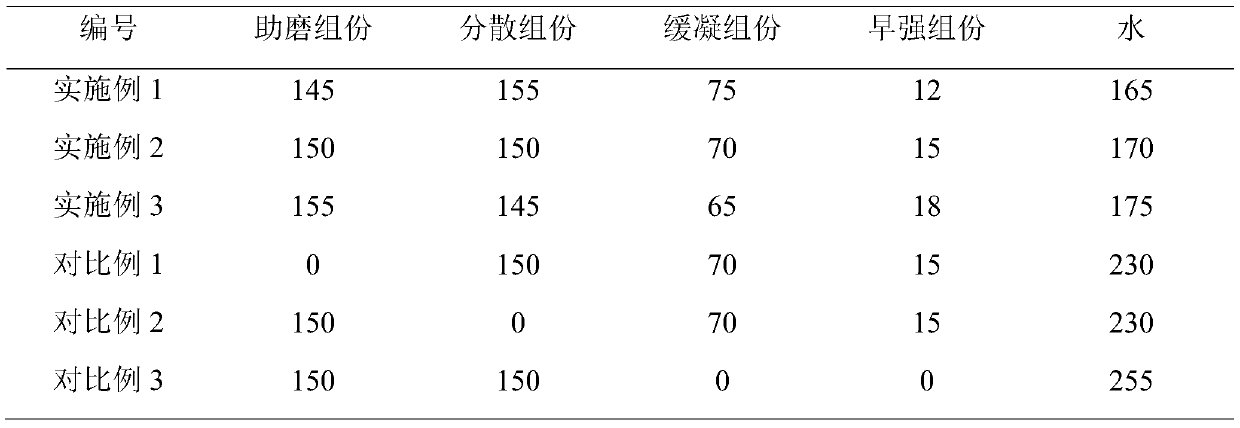

[0023] A compound type wet grinding concrete waste slag functional additive, its components and the mass parts of each component refer to Table 1. The specific preparation steps are: according to the mass parts, the grinding aid component, the dispersing component, the retarding component Components, early-strength components, and water are added to the reactor and mixed evenly.

[0024] The grinding aid component is diethanol monoisopropanolamine and triethanolamine composition with a mass ratio of 1:2;

[0025] Its dispersing components are single-end dihydroxy polyethylene glycol-isophorone diisocyanate copolymer and single-end dihydroxy polyethylene glycol-isophorone diisocyanate copolymer with a mass ratio of 1:1. The molecular weights of the compounds are all 3000-5000.

[0026] Its retarding component is molasses;

[0027] The early strength component is a composition of calcium nitrate and sodium silicate with a mass ratio of 1:2.

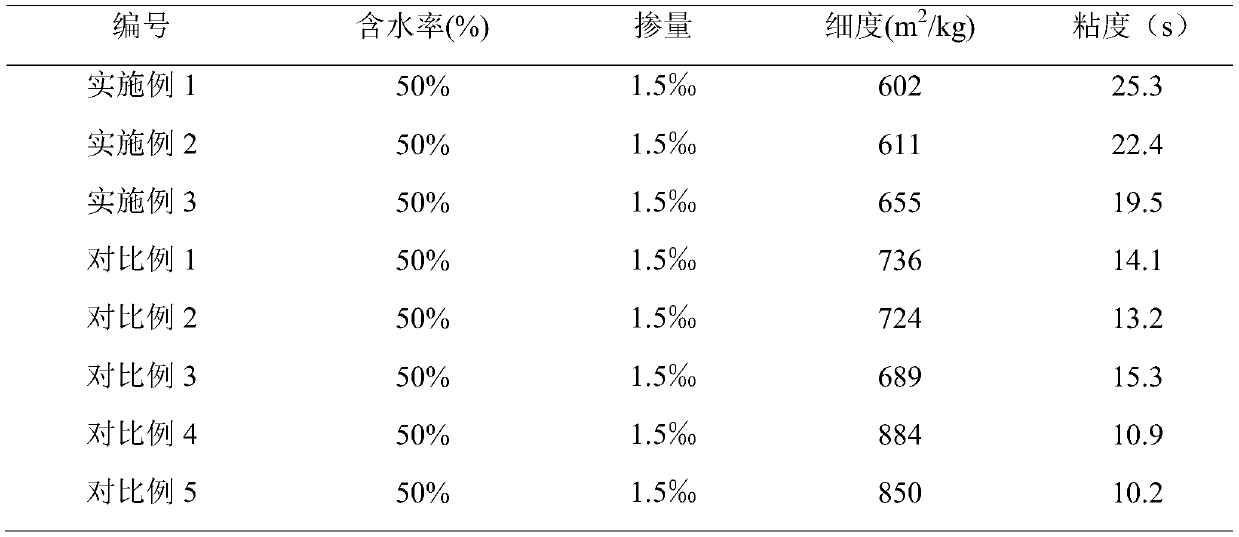

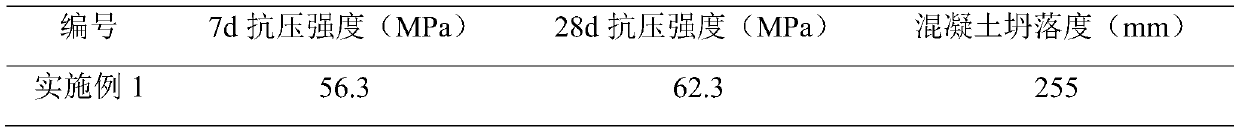

[0028] The specific performance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com