Environment-friendly and fireproof building sound insulation material and preparation method thereof

A technology of fire-proof building and sound-proof material, which is applied in the field of building sound-proofing, can solve the problems such as unsatisfactory fire-proof and sound-proof performance, achieve the effects of improving fire-proof and sound-proof performance, preventing moisture absorption and storage decomposition, and improving fire-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

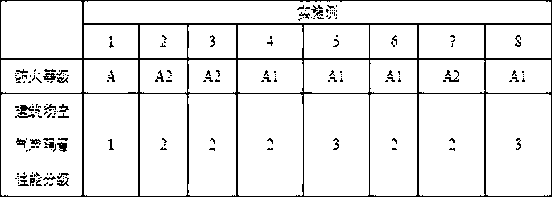

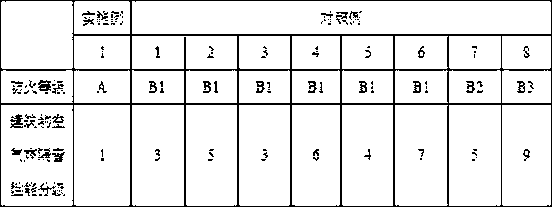

Examples

Embodiment 1

[0022] A sound-insulating material for an environment-friendly fireproof building, the preparation method of which comprises the following steps:

[0023] (1), Weigh 7.5 parts of acrylic acid, 23 parts of bisphenol A epoxy acrylate, 9.9 parts of water, 7 parts of SR-10 emulsifier and 0.5 parts of 819 photoinitiator and add them to the reaction kettle, the stirring speed is 95r / min , keep the system temperature at 33 °C for 15 minutes, add 59 parts of amylopectin to the reaction kettle at 0.04 parts / min, raise the temperature of the reaction kettle to 58 °C and continue the reaction for 27 minutes, and the product is illuminated by a 2000W high-pressure mercury lamp for 5 seconds , transfer the product to a ball mill, maintain the ball milling temperature at 38°C, and the cylinder rotation speed at 17r / min for ball milling reaction for 50min. Under the protection of nitrogen, transfer the product to a muffle furnace. The product is heat-treated at 100°C for 1 hour, and heat-trea...

Embodiment 2

[0029] A sound-insulating material for an environment-friendly fireproof building, the preparation method of which comprises the following steps:

[0030](1), Weigh 6 parts of acrylic acid, 16 parts of bisphenol A epoxy acrylate, 8 parts of water, 6 parts of SR-10 emulsifier and 0.4 parts of 819 photoinitiator and add them to the reaction kettle, the stirring speed is 95r / min , maintain the system temperature at 33 °C for 15 minutes, add 59 parts of amylopectin to the reactor at 0.04 parts / min, raise the temperature of the reactor to 53 °C and continue the reaction for 27 minutes, and the product is illuminated by a 2000W high-pressure mercury lamp for 3 seconds , transfer the product to a ball mill, maintain the ball milling temperature at 38°C, and the cylinder rotation speed at 17r / min for ball milling reaction for 50min. Under the protection of nitrogen, transfer the product to a muffle furnace. The product is heat-treated at 100°C for 1 hour, and heat-treated at 200°C. 2h...

Embodiment 3

[0036] A sound-insulating material for an environment-friendly fireproof building, the preparation method of which comprises the following steps:

[0037] (1), Weigh 9 parts of acrylic acid, 30 parts of bisphenol A epoxy acrylate, 15 parts of water, 10 parts of SR-10 emulsifier and 1 part of 819 photoinitiator and add them to the reaction kettle, the stirring speed is 95r / min , keep the system temperature at 33 °C for 15 minutes, add 59 parts of amylopectin to the reaction kettle at 0.04 parts / min, raise the temperature of the reaction kettle to 66 °C and continue the reaction for 27 minutes, and the product is illuminated by a 2000W high-pressure mercury lamp for 8 seconds , transfer the product to a ball mill, maintain the ball milling temperature at 38°C, and the cylinder rotation speed at 17r / min for ball milling reaction for 50min. Under the protection of nitrogen, transfer the product to a muffle furnace. The product is heat-treated at 100°C for 1 hour, and heat-treated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com