Silicon wafer processing device and processing technology for chip preparation

A technology for processing devices and silicon wafers, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as temperature softening deformation, clamping device offset, and lack of silicon wafer 4, so as to prevent softening and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

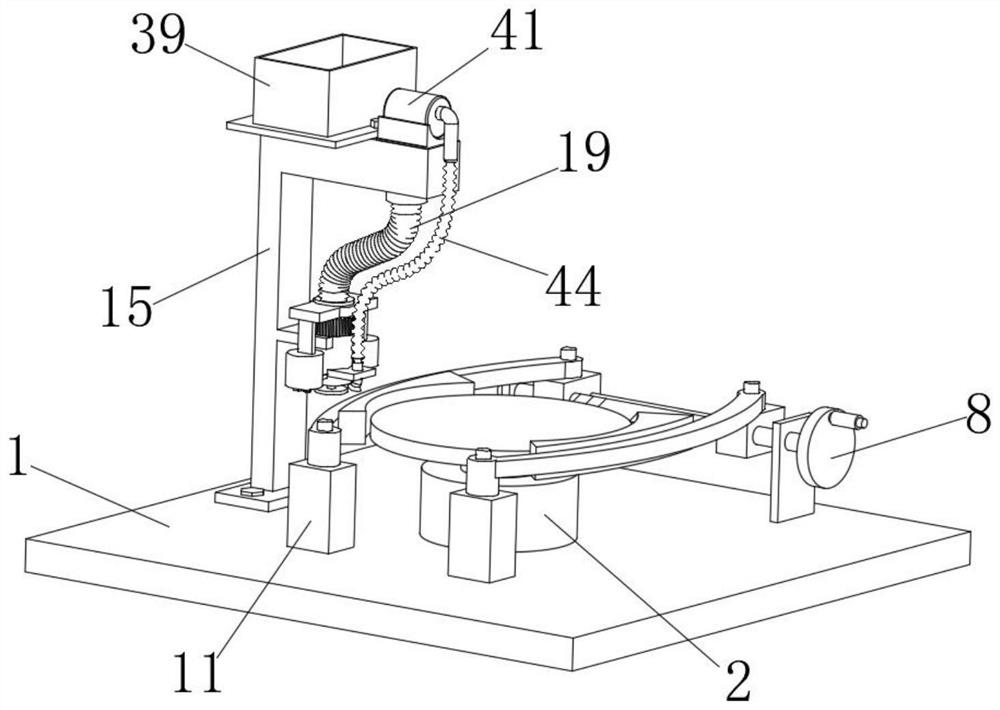

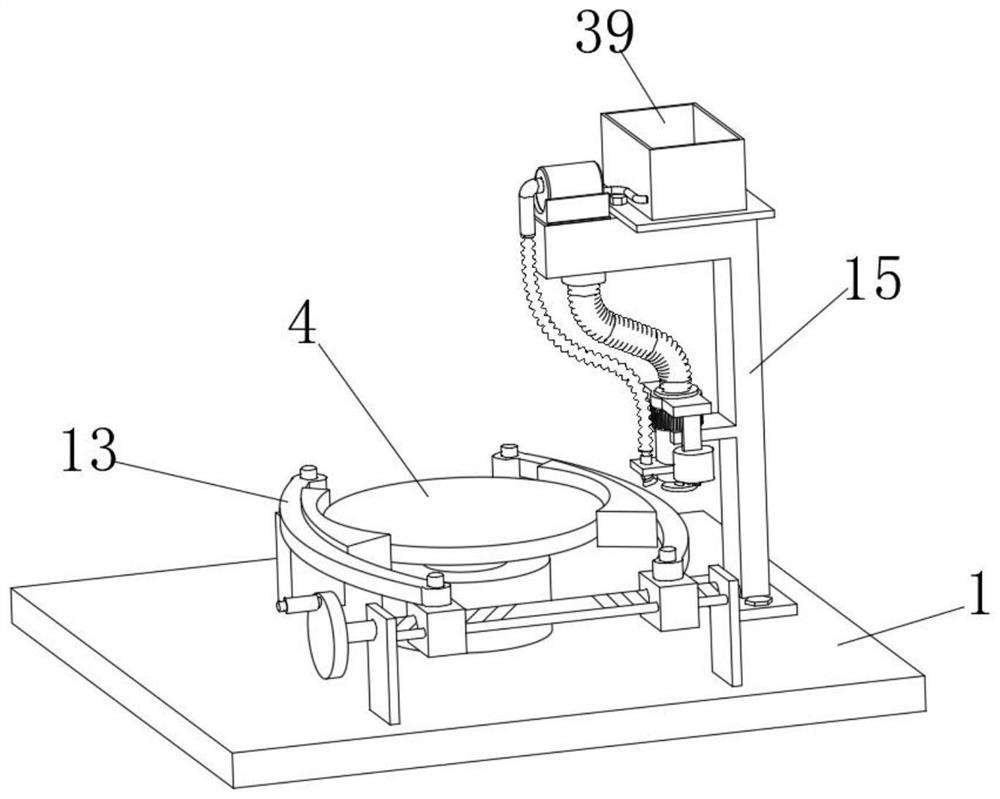

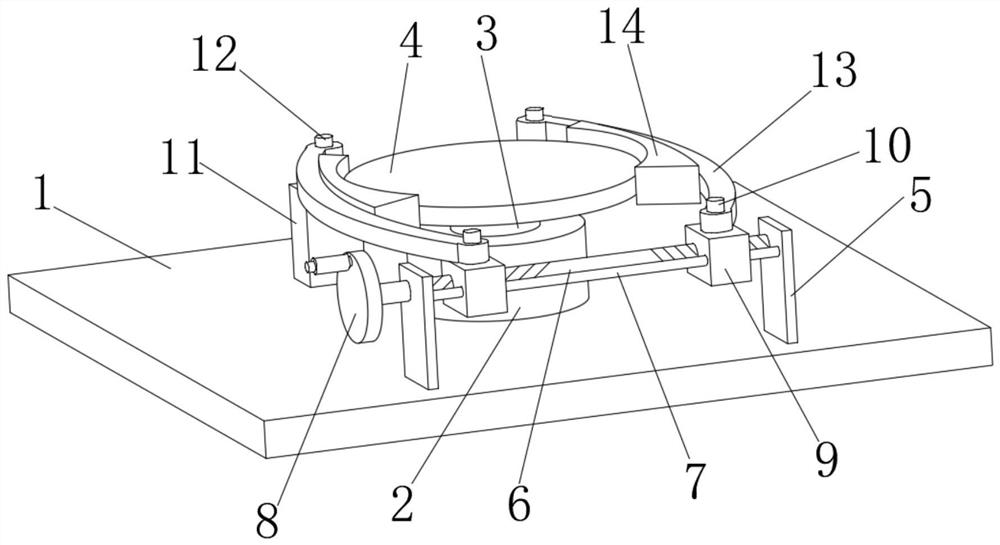

[0034] In a typical implementation of the present application, such as Figure 1-8As shown, a silicon wafer processing device for chip preparation includes a base plate 1, a support column 2 is fixedly connected to the top of the base plate 1, a support platform 3 is fixedly connected to the top of the support column 2, and a silicon wafer is arranged on the top of the support platform 3 4. The top of the bottom plate 1 is fixedly connected with two fixed plates 5, and the side walls of the two fixed plates 5 are provided with rotating holes, and the same two-way threaded rod 6 is connected to the rotating socket in the two rotating holes. The two ends of the rod 6 pass through the rotating holes respectively, and extend to the outsides of the two fixed plates 5. One end of the two-way threaded rod 6 is fixedly connected with a hand wheel 8, and two sliding blocks 9 are screwed on the two-way threaded rod 6. Perforations are provided on one side wall of each sliding block 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com