Fully-automatic feeding device for safe and efficient grinding machine

A technology of feeding device and grinding wheel machine, which is applied in the direction of grinding/polishing safety device, grinding machine tool parts, grinding feed movement, etc. It can solve the problems of affecting the working process, troublesome manual screening, long time consumption, etc., and achieves Speed up efficiency, convenient grinding, and speed up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

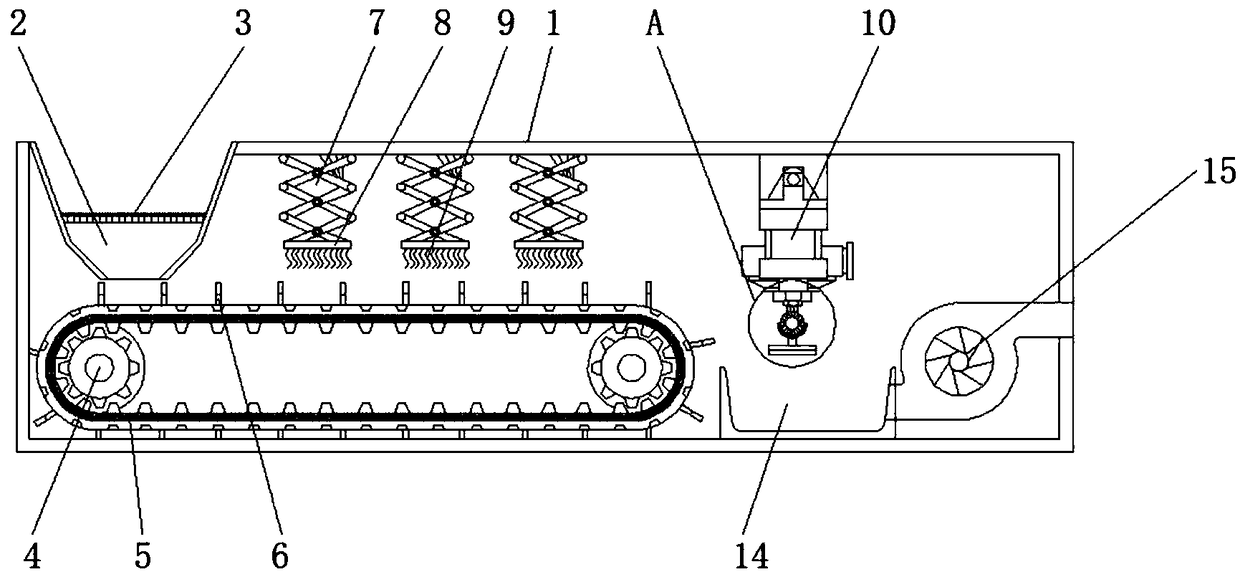

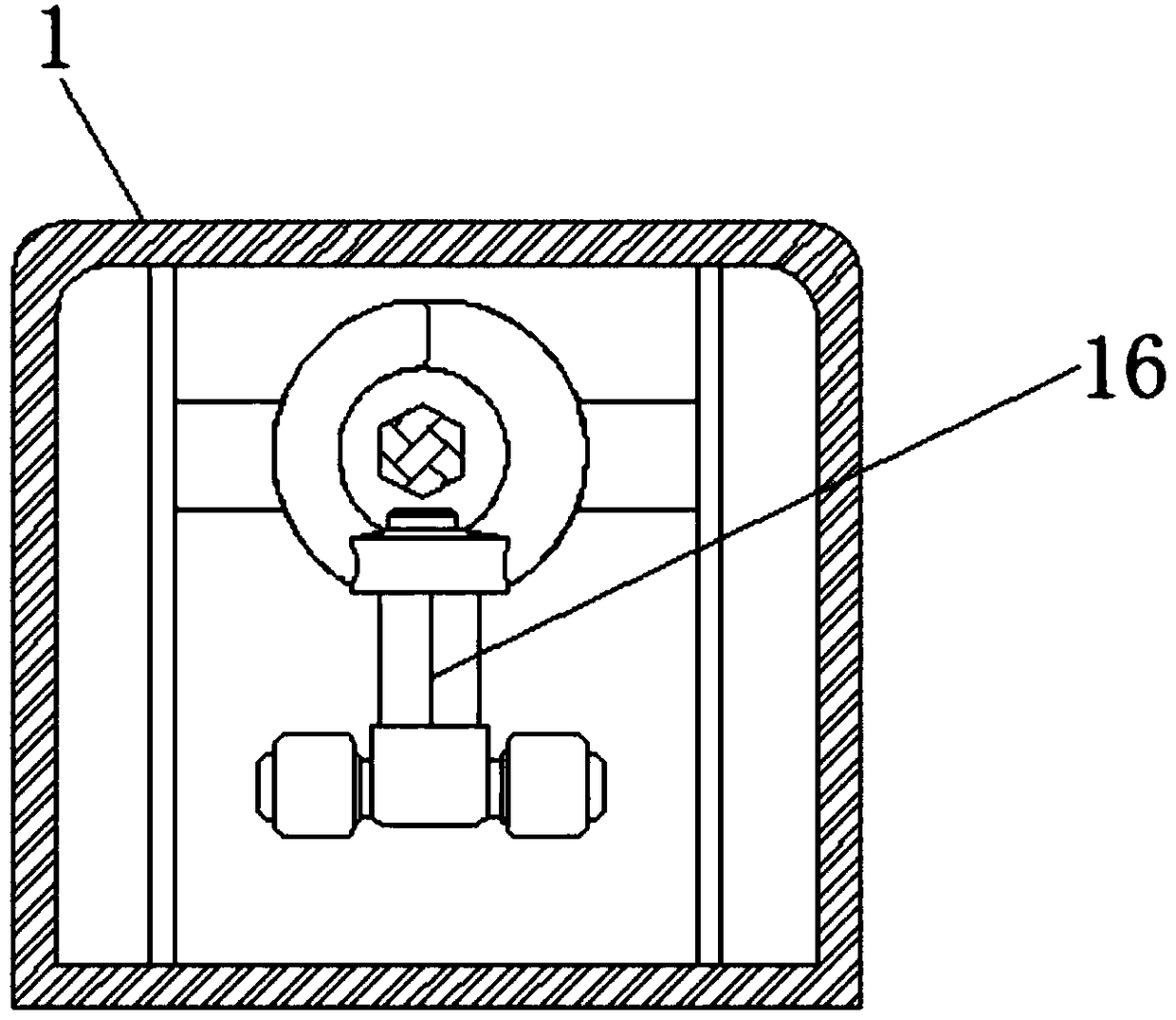

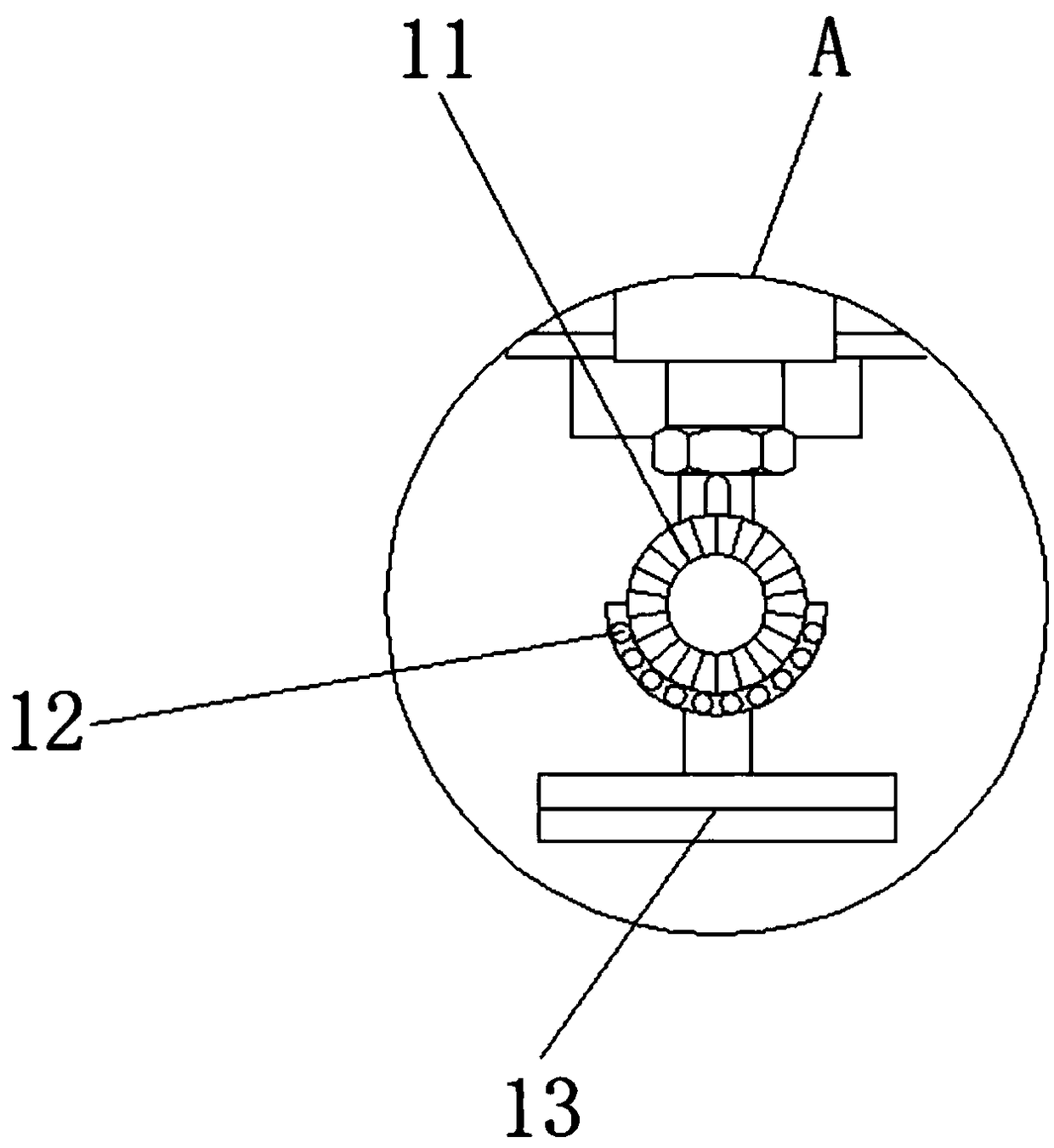

[0017] see Figure 1-3 , the present invention provides a technical solution: a fully automatic feeding device for a safe high-speed grinder, including a main body 1, a feeding port 2, a screen 3, a motor 4, a conveyor belt 5, a fixed plate 6, a hydraulic rod 7, and a turntable 8 , cleaning brush 9, grinder 10, ball 11, roller 12, grinding wheel sheet 13, grinding groove 14, exhaust fan 15 and handle 16, the top of main body 1 runs through feed port 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com