Automatic feeding and polishing device, production line with same and method

A technology of automatic feeding and material rack, which is applied in the direction of grinding drive device, parts of grinding machine tools, machine tools suitable for grinding workpiece edges, etc., which can solve problems such as affecting grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

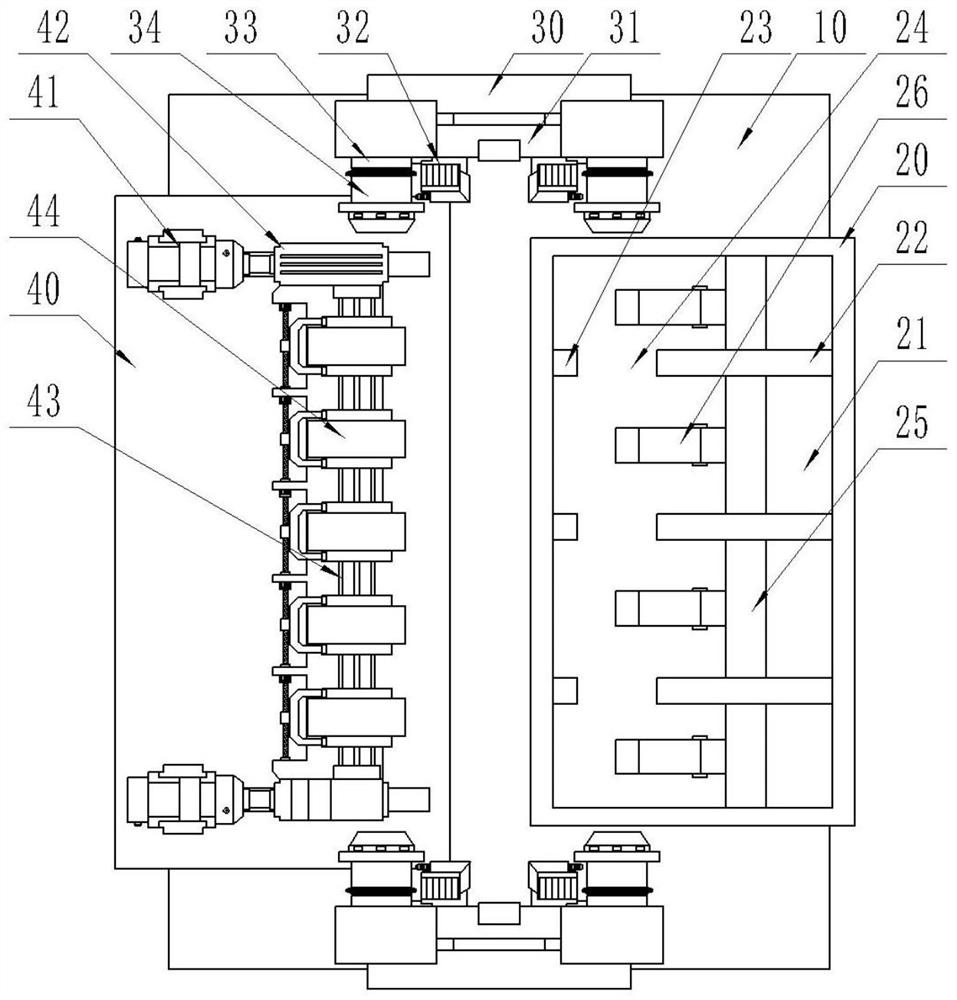

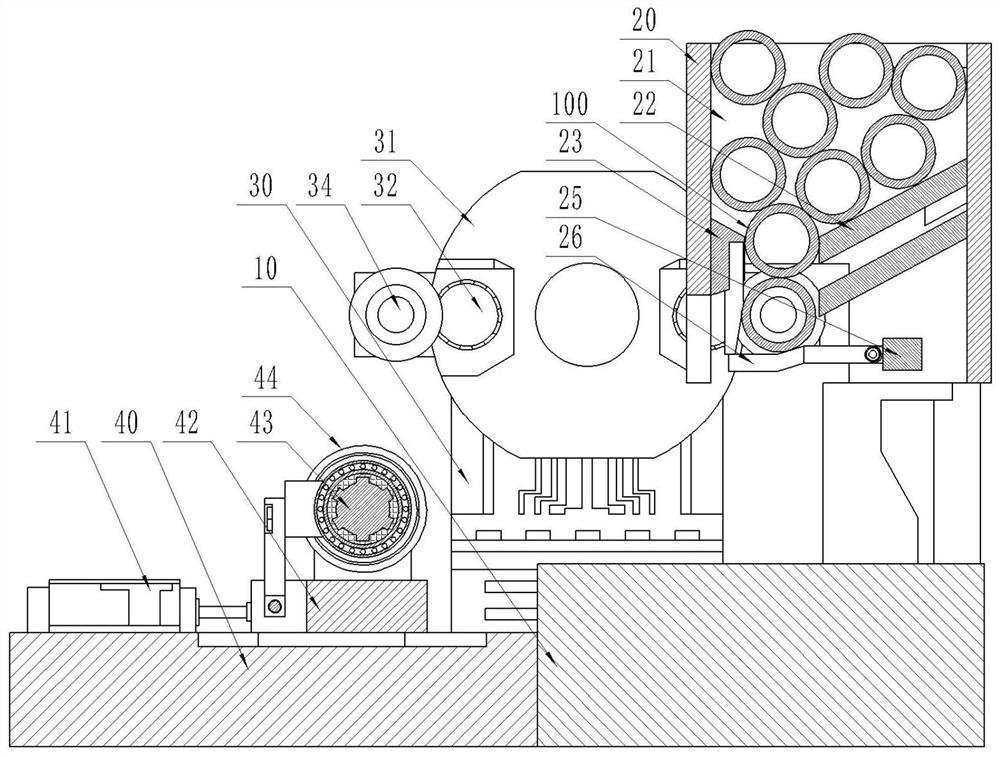

[0080] An automatic feeding grinding device, wherein, such as figure 1 , 2 As shown, a base 10 is included, and the base 10 includes: a loading frame 20 , a rotating and fixing mechanism 30 , and a grinding seat 40 .

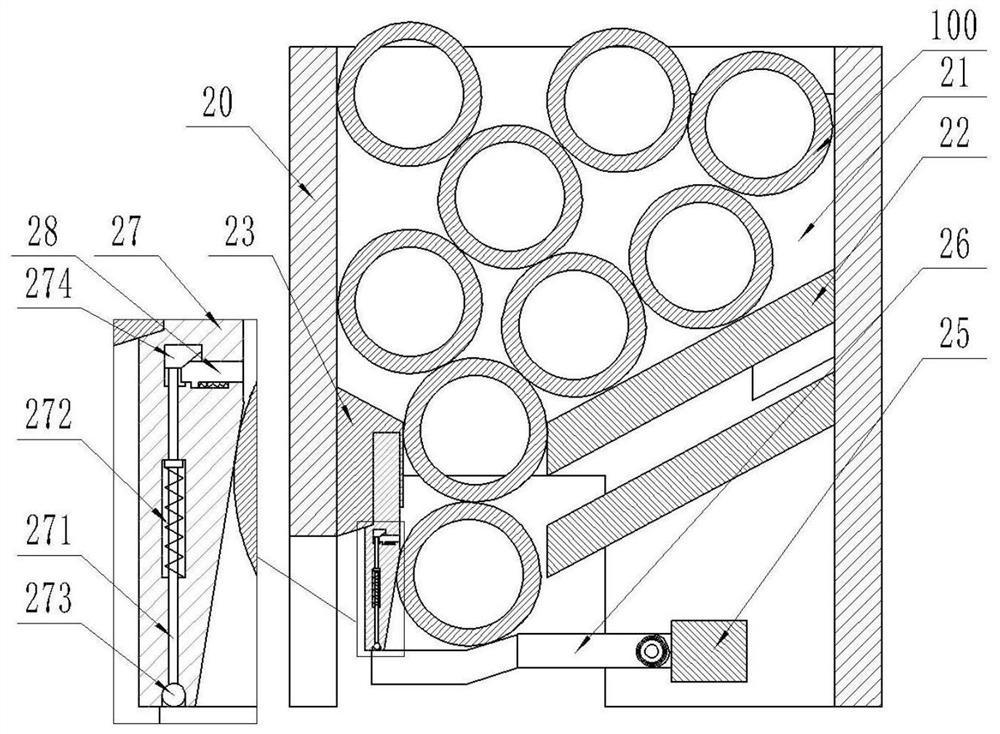

[0081] Such as figure 2 , 3 As shown, the loading rack 20 is installed on the right side of the base 10, the loading rack 20 has a storage space 21 for storing steel pipes to be polished, and the loading rack 20 also has: a right guide plate 22, a left guide plate 23, a fixed beam 25, movable baffle 26, limit baffle 27.

[0082] The right guide plate 22 is obliquely installed on the right side wall of the storage space 21 . The left guide plate 23 is obliquely installed on the left side wall surface of the storage space 21, and a blanking opening 24 for the steel pipe to be polished is formed between the left guide plate 23 and the right guide plate 22. The fixed beam 25 is located under the right guide plate 22 , and the fixed beam 25 is placed horizontal...

Embodiment 2

[0104] An automatic feeding and polishing device has the same characteristic structure and effect as that of Embodiment 1, wherein, such as Figure 9 , 10 As shown, there are a plurality of grinding wheels 44 distributed along the length direction of the steel pipe, and gaps exist between the plurality of grinding wheels 44 .

[0105] The main shaft 43 is provided with external teeth 431 , and a sliding sleeve 45 is provided between the main shaft 43 and the grinding wheel 44 . The sliding sleeve 45 has tooth slots matching the external teeth 431 , and the external teeth 431 are embedded in the tooth slots.

[0106] Both sides of the sliding sleeve 45 are connected with bearings 46 , the left side of the bearing 46 is connected with a connecting plate 47 , and the connecting plate 47 is threadedly connected with a transmission screw 48 .

[0107] It is found in the actual grinding of the steel pipe by the grinding wheel 44 that when the grinding wheel 44 adopts an integral st...

Embodiment 3

[0111] A production line, which has the automatic feeding and polishing device of the first or second embodiment.

[0112] Such as Figure 8 As shown, the upper left side of the grinding seat 40 is provided with a mechanical rod 50, the mechanical rod 50 is used to hook the polished steel pipe, the left side of the mechanical rod 50 is provided with a transport line 60, and the transport line 60 is used to receive the Steel Pipe.

[0113] After the steel pipe is polished, start the telescopic cylinder 41 to drive the emery wheel 44 to reset, and then start the rotating disk 31 to drive the polished steel pipe to rotate to the left side. At this time, the mechanical rod 50 is driven to rotate, so that the mechanical rod 50 hooks the steel pipe and stops turning to the electromagnet. 331 power supply, so that the clamping head 34 resets under the action of the pressure spring, and continue to rotate the mechanical rod 50, so that the mechanical rod 50 pushes the steel pipe to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com