Grinding device for corrugated steel web steel box girder partition plate

A technology of corrugated steel web and steel box girder, applied in grinding machine, grinding feed motion, grinding workpiece support and other directions, can solve the problems of reduced construction efficiency, high grinding noise, long welding seam length, etc. quality, improve grinding efficiency, and achieve the effect of grinding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

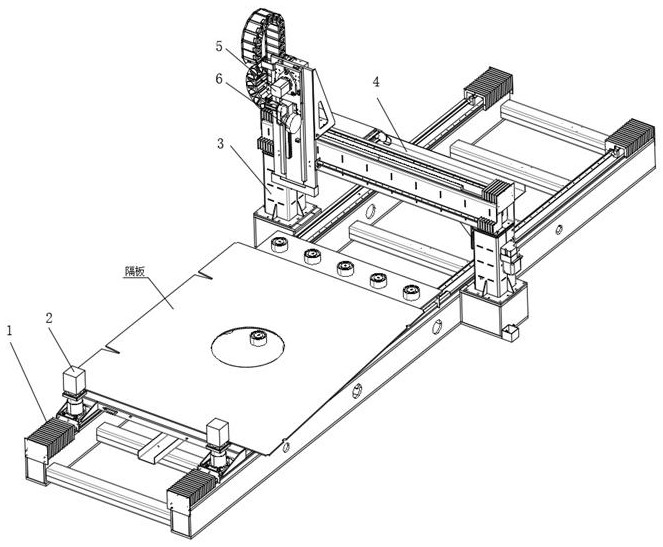

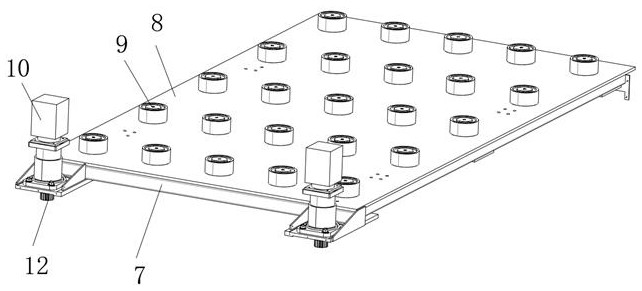

[0036] Such as Figures 1 to 6 As shown, a grinding device for corrugated steel web steel box girder partitions includes a fixed support base 1 , a transmission mechanism 2 , a support frame 3 , a lateral movement mechanism 4 , a longitudinal movement mechanism 5 and a grinding mechanism 6 . The fixed support base 1 provides basic support and fixation; the transmission mechanism 2 is used for the horizontal transportation of the partition and cooperates with the grinding mechanism 6 for grinding operation; the support frame 3 is used for the support and fixing of the transverse movement mechanism 4; the vertical movement mechanism 5 cooperates with the transverse The shifting mechanism 4 realizes the flexible adjustment of the grinding position of the grinding mechanism 6; the grinding mechanism 6 is used for automatic grinding of weld seams and corrosion areas.

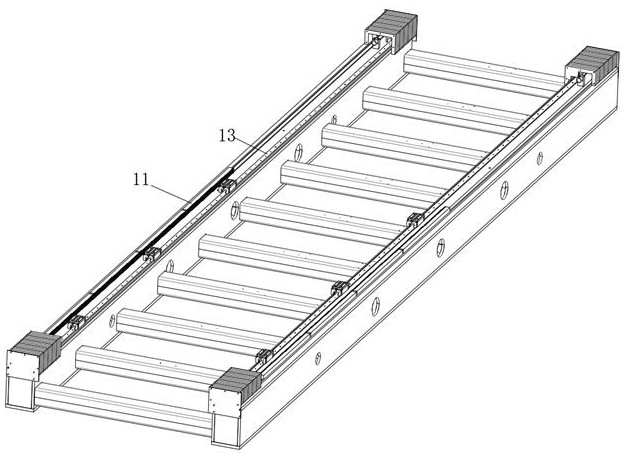

[0037] The fixed support base 1 has a lattice structure as a whole, which is similar to a ladder structure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com