Roadbed filling material using red sandstone and production method thereof

A technology of roadbed filler and production method, which is applied in the field of backfill improvement, can solve the problems of poor red sandstone diagenesis, poor roadbed filler, and easy weathering, and achieve the effects of high maximum dry density, good compaction effect, and ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

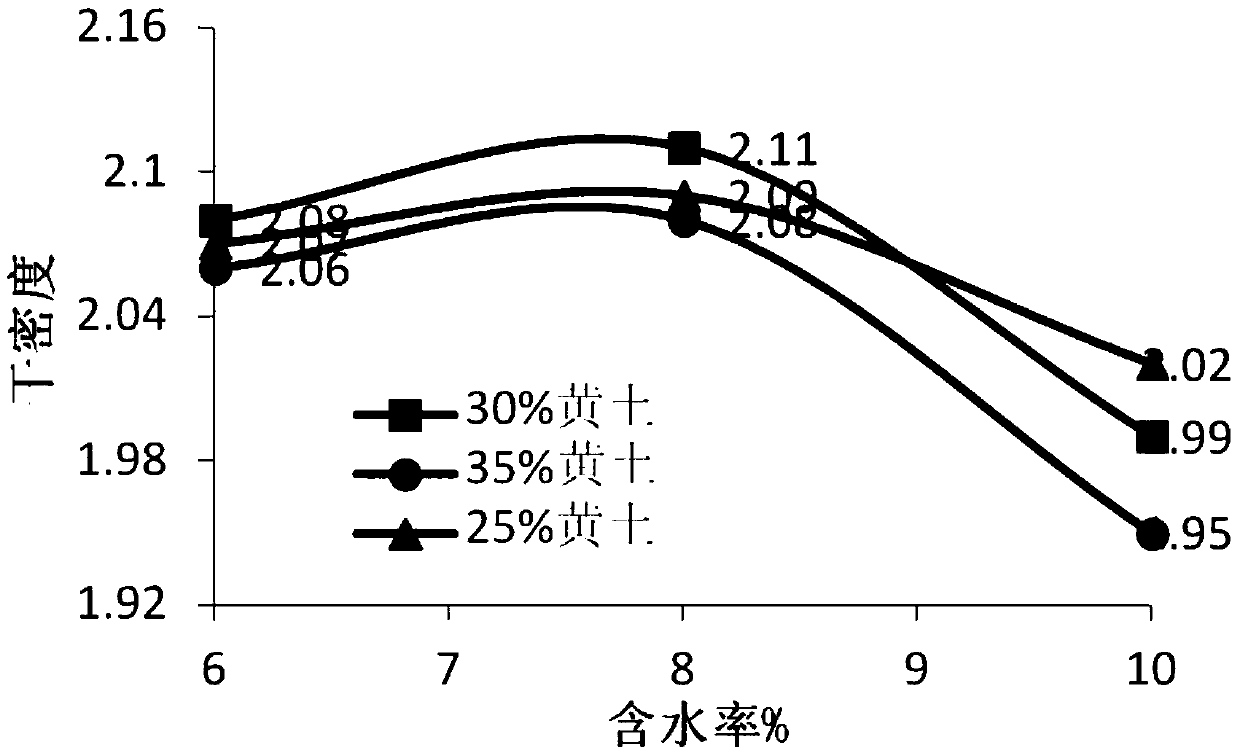

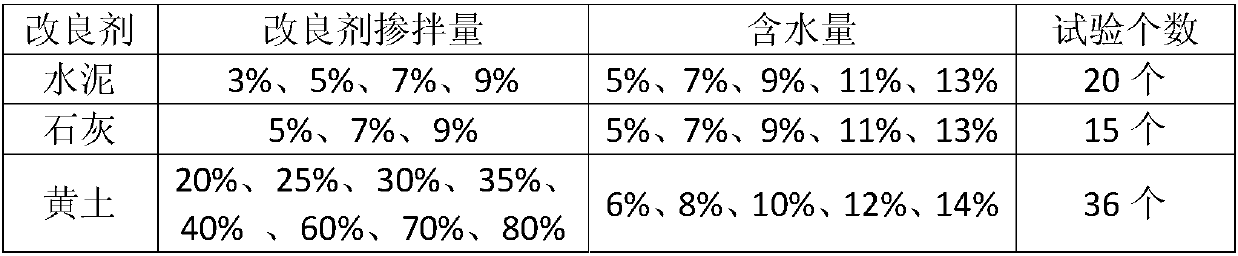

Embodiment 1

[0034] (1) Weigh clean plain loess and clean red sandstone respectively according to loess: red sandstone=0.25:0.75.

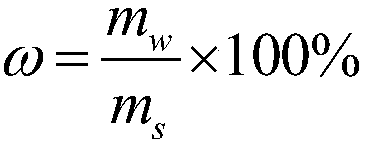

[0035] (2) After the red sandstone is fully crushed and crushed, it is evenly mixed with the loess, and the moisture content of the mixture is measured, and the moisture content is calculated according to the following formula:

[0036]

[0037] Among them, m w — mass of water, m s - Quality of dry soil.

[0038] Specifically, no less than three soil samples are taken from the mixture to measure their moisture content respectively, and their average value is taken as the moisture content of the mixture.

[0039] (3) Select 6% as the target moisture content. When the moisture content of the mixture is greater than 6%, use methods such as drying, drying, and air-drying to make the mixture reach a moisture content of 6%; when the moisture content is less than 6%, it is necessary to sprinkle water Treat to make the water content 6%, namely correspondingly ob...

Embodiment 2

[0043] The target water content in the step (3) of Example 1 is adjusted to 8%, that is, loess: red sandstone=0.25:0.75, the target water content is 8%, and other implementation contents and implementation steps are consistent.

Embodiment 3

[0045] The water content in step (3) of Example 1 is adjusted to 10%, i.e. loess: red sandstone=0.25:0.75, the target water content is 10%, and other implementation contents and implementation steps are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com