Design method for mixture ratio of lime-flyash stabilized crushed-stones based on mucilage theory

A mix ratio design and fly ash technology, applied in the field of transportation civil engineering, can solve the problems of mismatch between the maximum dry density and the optimum water content, and the inability to accurately predict the physical and mechanical properties of fly ash crushed stone, etc., to achieve excellent road performance , high dry density and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

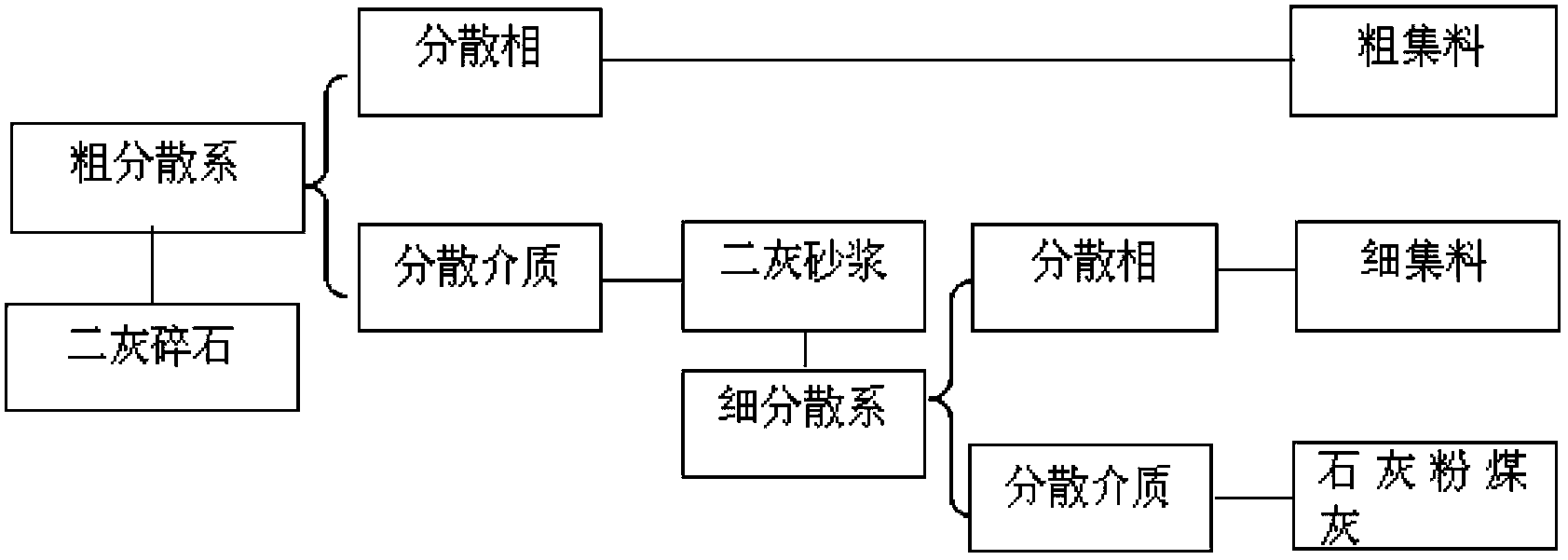

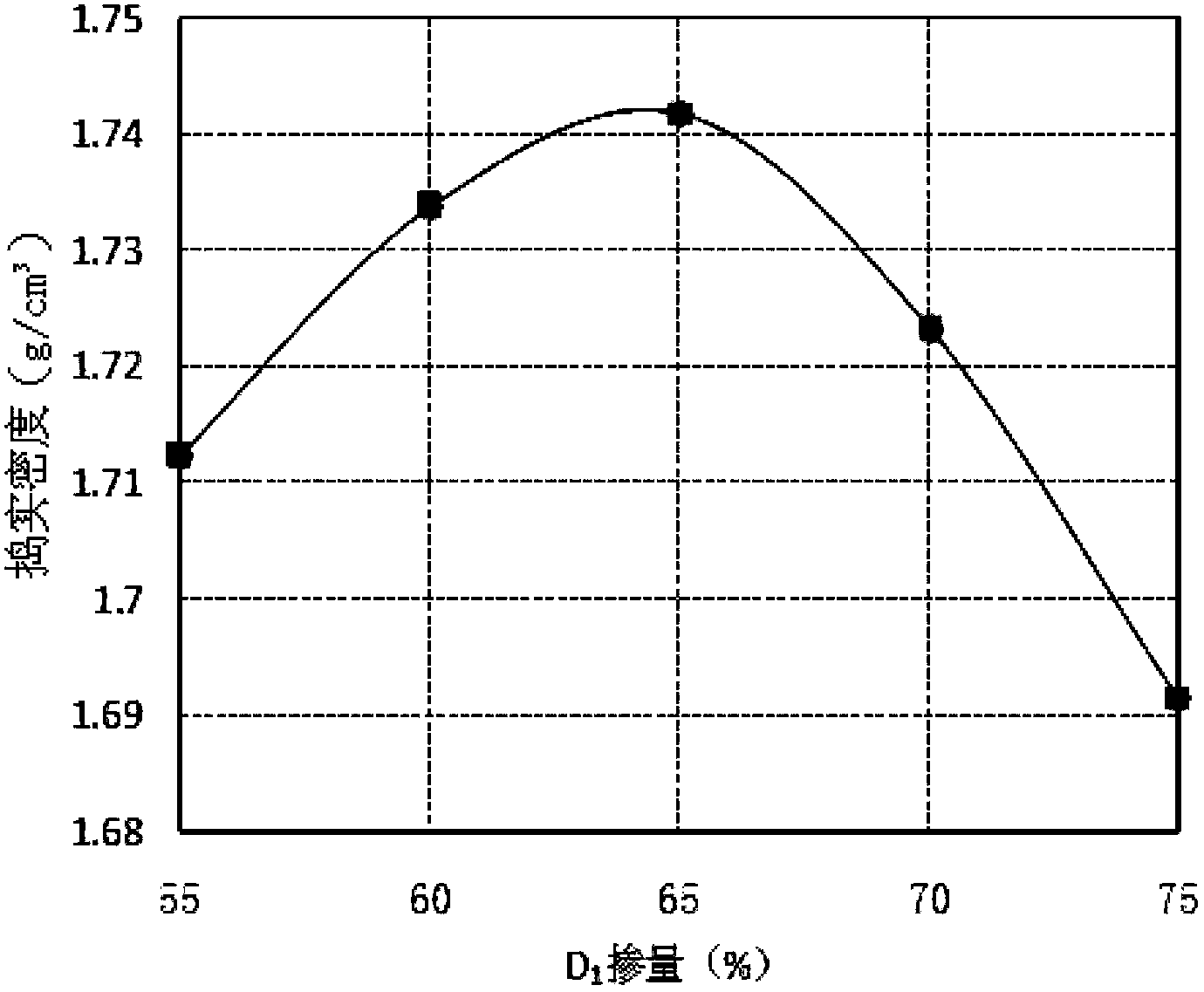

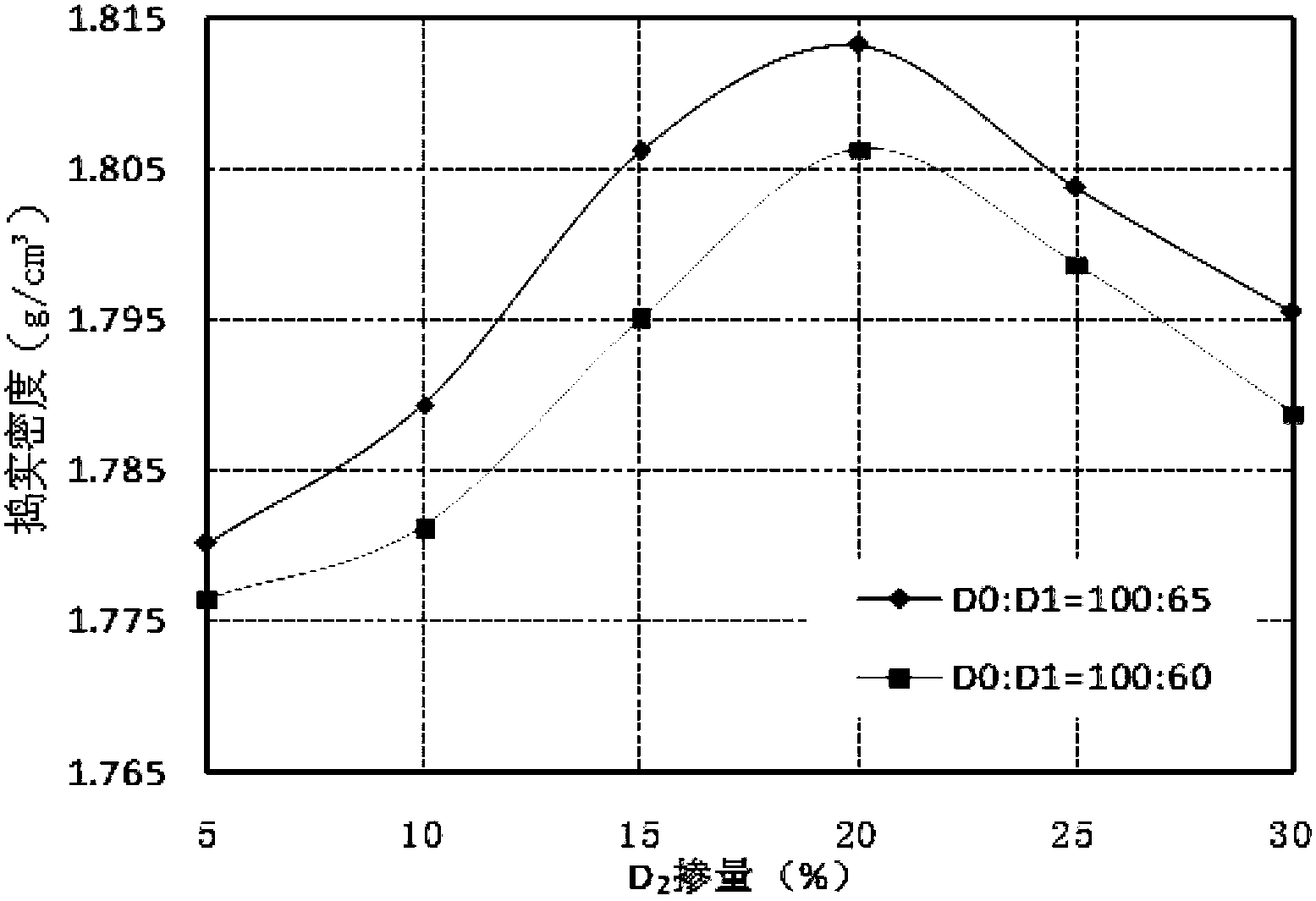

[0063] see Figure 2 ~ Figure 6 , a lime fly ash stabilized crushed stone mix design method based on the mortar theory, the method is carried out according to the following steps:

[0064] 1. Selection of raw materials

[0065] 1.1 Testing of the technical properties of the raw materials. The lime used was fired in the ash plant of Huangbaoyi in Tongchuan City, Shaanxi Province. The effective CaO+MgO content was 60.94%. The fly ash was produced in Tongchuan City Huaneng Power Plant. The chemical composition is shown in Table 2. The aggregate is limestone from Sunyuan Stone Factory in Tongchuan City, Shaanxi Province, which is divided into four specifications: 19-37.5mm, 9.5-19mm, 4.75-9.5mm, and stone chips. The screening results are shown in Table 3, and the indicators are shown in Table 4;

[0066] Table 2 Chemical composition of fly ash

[0067]

[0068] Table 3 aggregate screening results

[0069]

[0070] Table 4 aggregate technical indicators

[0071]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com