Mix proportion design method of cement stabilized regenerated gravel containing waste brick fine aggregate

A mix ratio design, cement stabilization technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of low strength and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

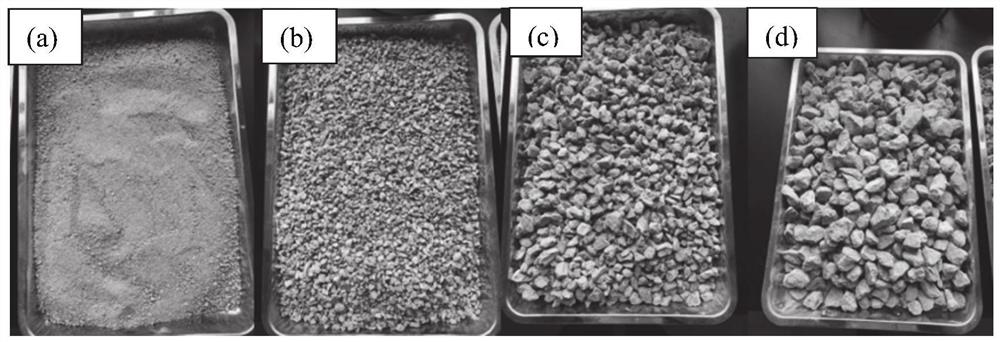

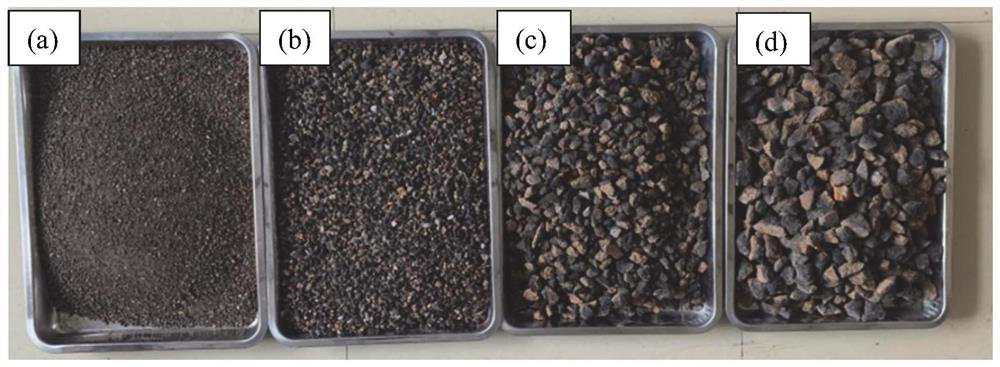

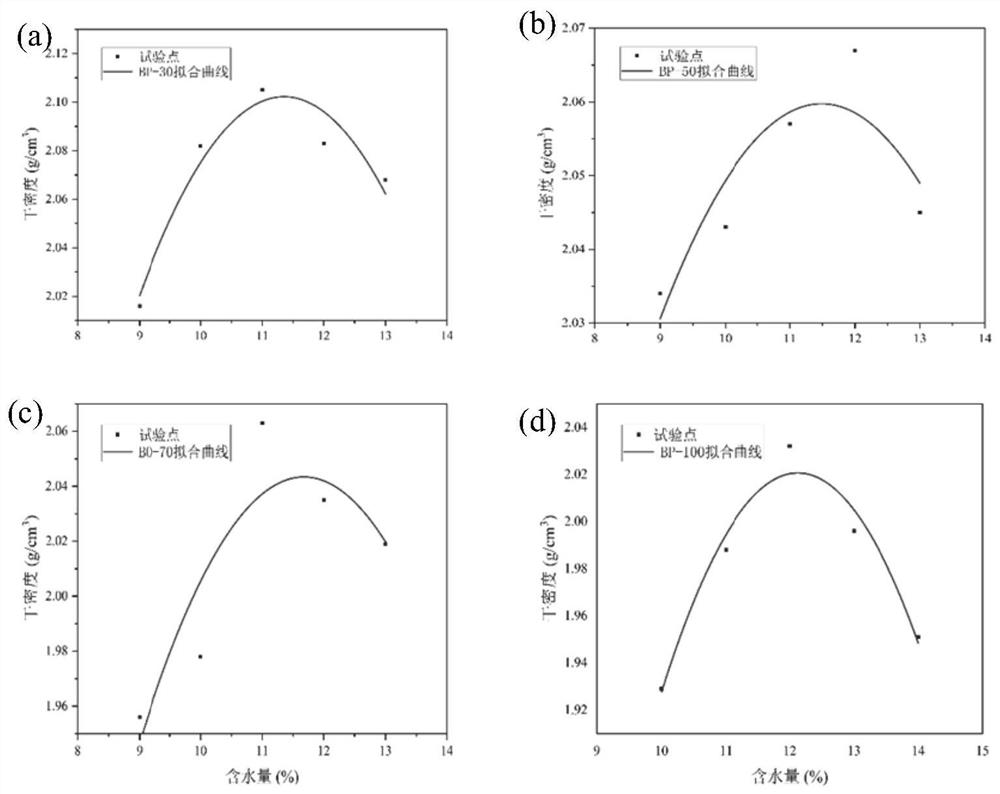

[0050] A design method for the mix ratio of cement-stabilized recycled crushed stone containing waste brick fine aggregate is proposed to solve the problems of high waste brick content and difficult sorting in urban construction waste, and a heavy-duty compaction test of the mixture is carried out according to the synthetic gradation And 7d age unconfined compressive strength experiment, to verify the use of waste brick fine aggregate instead of waste concrete recycled aggregate in the field of cement stabilized base, especially the performance of cement stabilized recycled gravel containing waste brick fine aggregate.

[0051] In the following examples, the heavy compaction test of the mixture and the unconfined compressive strength test at 7d age were carried out according to the synthetic gradation to verify the performance of the mixture. In this test, composite Portland cement with the label number 42.5 was used, and the cement dosage was 5%. The test chose a mineral mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com